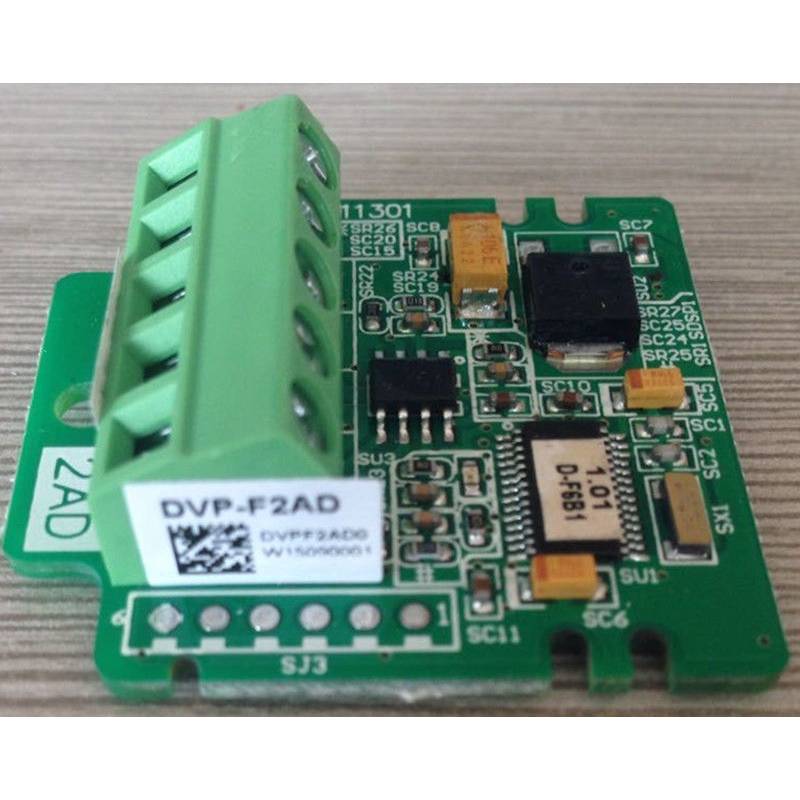

Delta DVP-F2AD: Precision Analog Signal Acquisition for Industrial Automation

The Delta DVP-F2AD is a high-performance, 2-channel analog signal input module designed to seamlessly integrate with Delta's DVP series Programmable Logic Controllers (PLCs). This module excels in providing accurate and reliable analog-to-digital conversion for a wide array of industrial applications. Key advantages include its precise 12-bit resolution, flexible input signal configuration, and robust construction, ensuring stable operation in demanding environments. Technical specifications highlight its broad input voltage and current ranges, making it adaptable to various sensor outputs and control signals.

Product Specifications

| Parameter | Specification |

| :-------------------- | :--------------------------------------------- |

| Number of Channels | 2 |

| Resolution | 12-bit |

| Input Signal Types | Voltage (e.g., ±10V, 0-10V, 0-5V) |

| | Current (e.g., ±20mA, 0-20mA, 4-20mA) |

| Input Voltage Range | Typically ±10V, 0-10V, 0-5V (configurable) |

| Input Current Range | Typically ±20mA, 0-20mA, 4-20mA (configurable) |

| Conversion Time | Varies by model, often < 10ms |

| Isolation | Channel-to-channel and channel-to-ground |

| Power Consumption | Typically < 1W |

| Operating Temperature | -10°C to 55°C |

| Dimensions | Compact module size for DIN rail mounting |

Core Features & Market Positioning

The DVP-F2AD distinguishes itself through its superior accuracy and versatility, essential for applications requiring precise measurement of physical parameters. Its 12-bit resolution offers a granular level of detail in data acquisition, which is critical for advanced process control and monitoring. Market positioning places the DVP-F2AD as a cost-effective yet highly capable solution for expanding the analog input capabilities of Delta's widely adopted DVP PLC series. It competes effectively by offering a balance of performance, reliability, and ease of integration, making it a preferred choice for system integrators and OEMs seeking dependable analog signal processing. Competitively, it provides a robust alternative to more expensive or complex solutions for standard analog input requirements.

Key Application Scenarios

The Delta DVP-F2AD analog input module is ideally suited for a multitude of industrial automation tasks where accurate sensing and measurement are paramount. It is frequently employed in process control systems for monitoring variables such as temperature, pressure, flow rates, and level sensors. In manufacturing, it facilitates precise control of machinery by converting analog signals from potentiometers, joysticks, or load cells into digital values usable by the PLC. Common applications include environmental monitoring systems, chemical dosing apparatus, precise motor speed control via variable frequency drives (VFDs), and automated assembly lines where feedback loops are crucial for optimal performance.

Practical System Integration Guidance

Integrating the Delta DVP-F2AD into a DVP PLC system is a straightforward process, typically involving direct connection to the PLC's expansion slot. Wiring requires careful attention to the input signal type (voltage or current) and the corresponding terminal connections on the module. Configuration is usually performed via the Delta ISPSoft programming software, where users define the input range, filtering, and other parameters to match the connected sensors. For example, configuring the module for a 4-20mA current loop input involves correctly wiring the sensor to the current input terminals and setting the appropriate mode within the PLC's I/O configuration in the software. It's vital to ensure proper grounding to mitigate noise interference and maintain signal integrity.

Operation and Risk Mitigation

Safe operation of the DVP-F2AD module hinges on adhering to standard electrical safety protocols. Before any wiring or configuration changes, always ensure power to the PLC system is safely de-energized. Proper installation within an appropriate enclosure is recommended to protect against environmental hazards such as dust, moisture, and electrical shock, especially since it is an open-type device. Incorrect wiring, such as applying AC power to analog terminals, can cause irreparable damage. Troubleshooting typically involves verifying wiring continuity, checking PLC program logic for correct data handling, and confirming module configuration parameters. Common issues can arise from signal noise, which can be mitigated by using shielded cables and proper grounding techniques. Fault codes, if generated by the PLC, should be cross-referenced with the PLC's system manual for specific diagnostic information.

Scalability & Long-Term Value

The DVP-F2AD offers significant long-term value through its compatibility with the extensive Delta DVP PLC ecosystem. As an expansion module, it enhances the analog input capabilities of existing DVP series PLCs, such as the EH3 series, without requiring a full system replacement. This modular approach allows for scalable system design, enabling users to add more analog I/O as application demands grow. Furthermore, the DVP-F2AD integrates seamlessly with other Delta automation components, including HMIs, AC drives, and servo systems, forming a cohesive "Delta Solution". This interoperability supports the adoption of Industrial IoT (IIoT) and digital transformation initiatives by providing a solid foundation for data acquisition and control.

Frequently Asked Questions (FAQs)

Q1: What are the primary advantages of the Delta DVP-F2AD module?

The DVP-F2AD offers high-precision 12-bit analog-to-digital conversion, ensuring accurate signal acquisition. It supports versatile input ranges for both voltage and current signals, adapting to diverse sensor types. Its compact design and direct integration with Delta DVP PLCs simplify system expansion.

This module enhances the control capabilities of industrial automation systems by providing reliable analog data. It is designed for industrial environments, offering robust performance and longevity in demanding applications. Its cost-effectiveness makes it an attractive option for expanding I/O without significant capital investment.

The key advantage lies in its seamless integration within the Delta automation ecosystem, allowing for a unified system approach. This facilitates easier programming, troubleshooting, and maintenance when used alongside other Delta products.

Q2: How do I configure the input type (voltage or current) on the DVP-F2AD?

Input type configuration is typically done via software using Delta's ISPSoft programming environment. Within the PLC's hardware configuration, you select the DVP-F2AD module and define its operating mode.

This involves setting parameters for voltage or current input, and specifying the exact range (e.g., 0-10V or 4-20mA). Consult the module's specific datasheet or the DVP PLC operation manual for precise instructions.

Physical wiring also dictates the input type. Ensure the sensors are connected to the correct terminals designated for voltage or current signals as per the module's wiring diagram.

Q3: What is the resolution of the Delta DVP-F2AD module?

The Delta DVP-F2AD module features a 12-bit analog-to-digital converter. This means it can distinguish between 4096 discrete levels for the full input signal range.

A 12-bit resolution provides a good balance between accuracy and cost for many industrial applications. It allows for fine-grained measurement of analog signals, crucial for precise process control.

For applications requiring even higher precision, Delta may offer modules with higher resolutions, such as 14-bit or 16-bit converters, though the DVP-F2AD is optimized for general-purpose analog input tasks.

Q4: Can the DVP-F2AD be used with PLCs other than Delta's DVP series?

While the DVP-F2AD is designed as an expansion module for Delta DVP series PLCs, its use with other PLC brands is generally not supported or recommended. It relies on proprietary communication protocols and addressing schemes specific to Delta's PLC hardware and software.

Attempting to integrate it with non-Delta PLCs would likely require custom interface development and complex communication protocols, negating its plug-and-play advantages. Such integration would also void warranties and support.

For other PLC systems, it is best to use analog input modules specifically designed for those respective brands and platforms to ensure compatibility and reliable operation.

Q5: What voltage or current signals can the DVP-F2AD accept?

The DVP-F2AD module typically accepts standard industrial analog signals. For voltage, common ranges include ±10V, 0-10V, and 0-5V, which can be configured through software.

For current signals, it usually supports ±20mA, 0-20mA, and the widely used 4-20mA industrial standard, also selectable via software settings. Always verify the exact supported ranges in the product's technical specifications.

The versatility in signal input allows it to interface with a broad spectrum of sensors, transmitters, and analog output devices commonly found in industrial automation.

Q6: How is the DVP-F2AD module installed and wired?

Installation involves physically mounting the module onto a DIN rail adjacent to a compatible DVP PLC CPU or another expansion module. Wiring connections are made to the module's terminal blocks, which are clearly labeled for power, ground, and analog input channels.

Specific wiring depends on the signal type (voltage or current). For voltage signals, connect the sensor's output to the appropriate V+ and V- terminals. For current signals, connect the sensor to the I+ and I- terminals, ensuring correct polarity.

Always refer to the official Delta DVP-F2AD installation manual for detailed wiring diagrams and terminal assignments to prevent incorrect connections and potential damage.

Q7: What programming software is used with the DVP-F2AD module?

The Delta DVP-F2AD module is programmed and configured using Delta's ISPSoft software. This integrated development environment supports ladder logic, function block diagrams, and other IEC 61131-3 standard programming languages.

ISPSoft allows engineers to configure the module's input parameters, set scaling factors, and implement logic for processing the analog data within the PLC program. It also handles hardware configuration and communication management.

You can download the latest version of ISPSoft from the Delta Electronics official website, often bundled with other development tools like COMMGR for communication management.

Q8: What are the typical environmental operating conditions for the DVP-F2AD?

The DVP-F2AD is designed for industrial environments and typically operates within a temperature range of -10°C to 55°C. It also has specific humidity tolerance, usually around 5% to 95% non-condensing.

It is crucial to install the module within an enclosure that provides adequate protection against dust, moisture, vibration, and extreme temperatures. This ensures reliable performance and extends the module's operational lifespan.

Proper ventilation within the enclosure is also important to prevent overheating, especially when the PLC system is under heavy load or operating in a warm ambient environment.

Q9: Does the DVP-F2AD module provide isolation?

Yes, the Delta DVP-F2AD module typically provides isolation between the analog input channels and between the channels and ground. This isolation is critical for preventing ground loops and protecting the PLC and connected devices from electrical noise and voltage surges.

Isolation enhances the signal integrity by minimizing interference from external electrical sources. It also adds a layer of safety by electrically separating the low-voltage PLC circuitry from potentially higher voltages in the field.

Refer to the specific product datasheet for confirmation of isolation specifications and voltage ratings, as different versions or revisions might have slight variations.

Q10: How does the DVP-F2AD contribute to system scalability?

The DVP-F2AD contributes to system scalability by being a modular expansion component for the DVP PLC series. Users can add multiple DVP-F2AD modules to a single PLC to increase the number of analog input channels as needed.

This modularity allows systems to grow without requiring a complete overhaul of the PLC hardware. It provides a cost-effective way to enhance system capabilities incrementally.

Furthermore, the DVP-F2AD integrates with a wide range of Delta's other PLC modules and automation products, allowing for complex and scalable system architectures that can evolve with changing industrial demands.