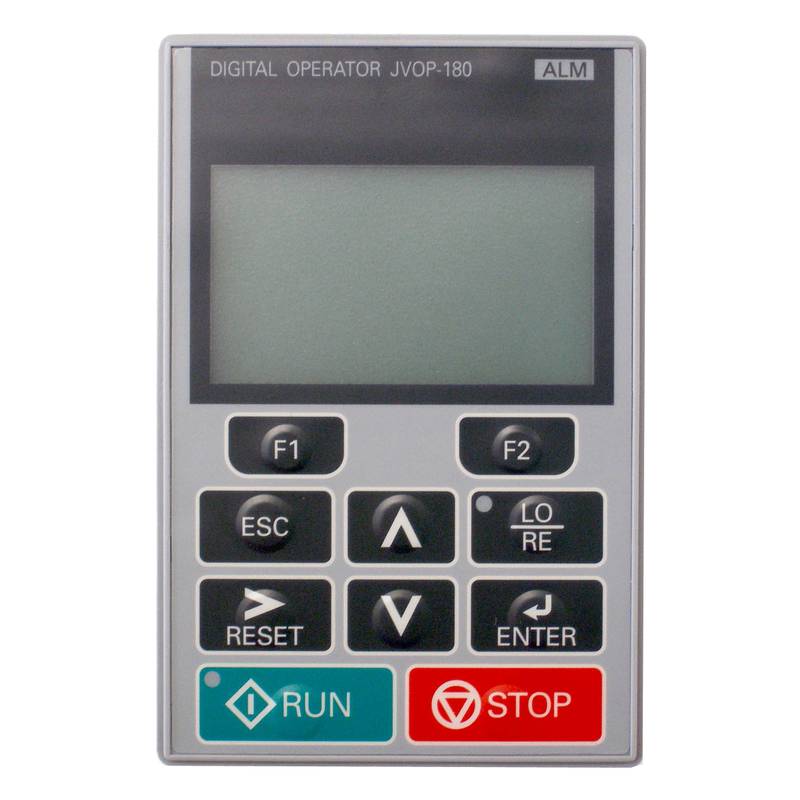

The Yaskawa JVOP-180 Portable Handy Operator is an essential interface device for Yaskawa's comprehensive range of AC drives, offering unparalleled control and monitoring capabilities for frequency converters. This compact, intuitive unit streamlines setup, operation, and troubleshooting, making it a critical component for engineers and technicians managing variable speed drives in diverse industrial applications. Key advantages include its robust design, user-friendly interface, and real-time data display, which significantly reduce commissioning time and enhance operational efficiency. The JVOP-180 boasts a 5-line LCD with 20 characters per line, allowing for clear parameter viewing and status updates, and features a 17-key keypad for easy navigation and input. Its operating temperature range of 0 to 50°C ensures reliable performance in standard industrial environments.

Product Specifications

| Feature | Specification |

| :---------------- | :----------------------------------- |

| Display | 5-line LCD (20 characters per line) |

| Keypad | 17-key |

| Operating Temp. | 0 to 50°C |

| Dimensions | Compact and portable |

| Compatibility | Yaskawa AC Drives |

Core Features & Market Positioning

The Yaskawa JVOP-180 stands out in the market due to its direct compatibility and seamless integration with Yaskawa's leading Varisol and other inverter series. This ensures optimized performance and eliminates the complexities often associated with third-party operator interfaces. Its portability allows for on-site adjustments and diagnostics, a significant advantage for maintenance teams. The device's ability to display multiple parameters simultaneously, such as frequency, voltage, current, and motor speed, provides operators with comprehensive system insight. This real-time feedback loop is crucial for fine-tuning machine performance and identifying potential issues before they escalate, positioning the JVOP-180 as a cost-effective solution for enhancing productivity and drive reliability.

Key Application Scenarios

The JVOP-180 Portable Handy Operator finds extensive use across various industrial sectors where precise motor control is paramount. In manufacturing, it facilitates the adjustment of conveyor belt speeds, pump flow rates, and fan volumes, optimizing production processes. For the food and beverage industry, it ensures consistent mixing speeds and packaging line synchronization. In the water and wastewater treatment sector, it allows for precise control of pump and fan speeds to manage flow and pressure efficiently. Machine builders also leverage the JVOP-180 for easy setup and parameterization of drives integrated into their equipment, simplifying the commissioning phase for end-users.

Practical System Integration Guidance

Integrating the Yaskawa JVOP-180 into a Yaskawa frequency converter system is straightforward. The operator typically connects via a dedicated communication port on the drive, often using a standard cable. For initial setup, technicians will navigate the intuitive menu structure to configure essential drive parameters like motor data, speed references, and acceleration/deceleration times. Many Yaskawa drives allow for parameter copying between units using the JVOP-180, significantly reducing the time required to set up multiple identical systems. Referencing the specific drive's manual is recommended for detailed wiring diagrams and advanced configuration options, ensuring proper interconnection and operational integrity.

Operation and Risk Mitigation

Operating the JVOP-180 involves navigating its menu system using the keypad to monitor drive status, adjust settings, and diagnose faults. Safety is a critical consideration; always ensure that the drive and connected machinery are properly de-energized before making any physical connections or significant parameter changes. Common troubleshooting steps involve checking error codes displayed on the operator's screen. For instance, an "OL" (Overload) warning might indicate a motor issue or an undersized drive, while an "E.OC" (Overcurrent) fault suggests a potential short circuit or rapid acceleration. Understanding these fault codes and their corresponding resolutions, often detailed in the drive's user manual, is key to minimizing downtime and preventing equipment damage.

Scalability & Long-Term Value

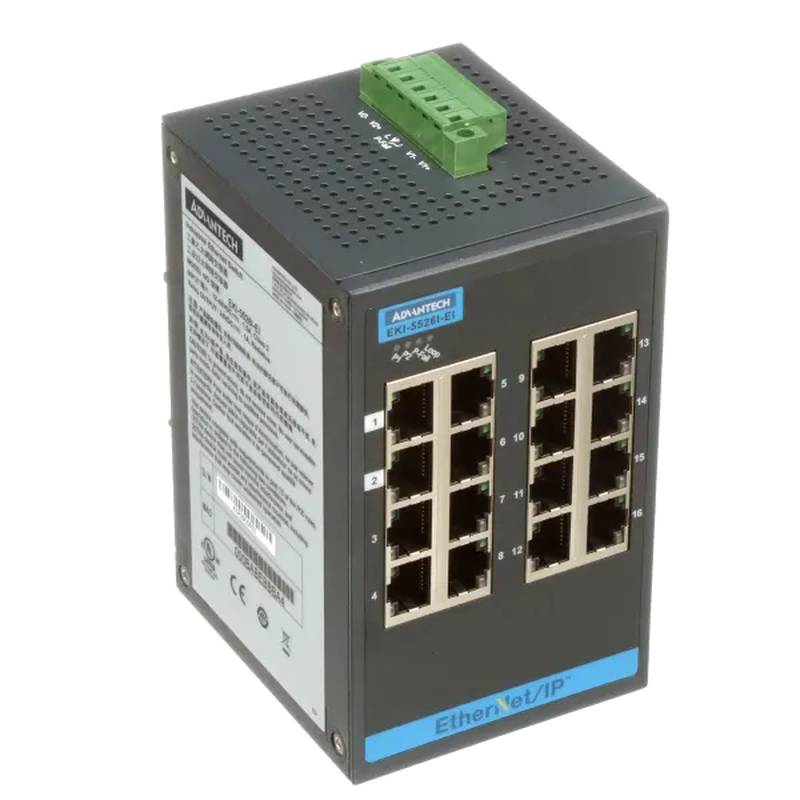

The long-term value of the Yaskawa JVOP-180 is rooted in its compatibility with a wide range of Yaskawa AC drives, ensuring it remains a relevant tool as systems evolve. While the JVOP-180 is a powerful portable operator, Yaskawa's ecosystem also supports more advanced network integration for Industrial Internet of Things (IIoT) and Industry 4.0 initiatives. This means that drives controlled by the JVOP-180 can often be integrated into supervisory control and data acquisition (SCADA) systems or cloud-based monitoring platforms, allowing for centralized data analysis and predictive maintenance strategies. This forward-looking compatibility ensures that investments in Yaskawa drive technology, including the use of the JVOP-180, provide enduring operational benefits.

Frequently Asked Questions

What is the primary function of the Yaskawa JVOP-180?

The JVOP-180 serves as a portable human-machine interface for Yaskawa AC drives. It allows users to monitor real-time operating data and adjust drive parameters directly from the operator panel. This enables precise control over motor speed, torque, and other essential functions for various industrial applications.

This portable operator is crucial for efficient commissioning and on-site adjustments. Its user-friendly design simplifies complex drive configurations. The device facilitates quick diagnostics and troubleshooting, minimizing operational interruptions.

Its core purpose is to provide a direct, intuitive link to Yaskawa frequency converters. This enhances operational flexibility and control in diverse manufacturing and process environments.

How do I connect the JVOP-180 to a Yaskawa frequency converter?

Connection is typically made through a dedicated communication port on the Yaskawa drive. You will need a specific Yaskawa communication cable designed for this purpose. Ensure the drive is powered off before connecting the operator to prevent damage.

Consult the specific Yaskawa drive model's user manual for the exact port location and recommended cable type. Proper cable selection ensures reliable data transmission and communication integrity.

Once physically connected, power on the drive and the JVOP-180 will usually initialize automatically. Parameters can then be accessed and modified via the operator's keypad and display.

What are some common error codes displayed on the JVOP-180?

Common error codes include "OL" (Overload), indicating the motor is drawing too much current, and "E.OC" (Overcurrent), suggesting a potential short circuit or rapid acceleration. Other frequent codes might relate to input/output phase loss or drive overheating.

Each error code signifies a specific fault condition within the drive or connected motor system. The Yaskawa drive's manual provides a comprehensive list of these codes and their corresponding troubleshooting procedures.

Interpreting these codes is vital for effective problem-solving. Addressing the root cause promptly prevents further equipment damage and minimizes costly downtime.

Can the JVOP-180 be used with Yaskawa drives other than specific models?

The JVOP-180 is designed for compatibility with a wide range of Yaskawa AC drives, particularly within the Varisol series and other compatible inverter families. However, specific compatibility should always be verified.

Check the specifications of both the JVOP-180 and your Yaskawa drive model. Yaskawa provides compatibility charts or technical documentation to confirm if they can be used together.

Using an incompatible operator can lead to communication errors or operational failures. Always refer to official Yaskawa documentation for definitive compatibility information.

What is the main advantage of using a portable operator like the JVOP-180?

The primary advantage is enhanced operational flexibility and ease of use for technicians and engineers. Its portability allows for direct interaction with drives in various locations, streamlining setup and maintenance tasks.

This direct interface enables real-time monitoring and parameter adjustments without needing to access the drive's internal controls or a remote control panel. This saves significant time and effort.

The intuitive keypad and clear LCD display simplify complex drive programming, making it accessible even for those less familiar with advanced control systems. This reduces the learning curve and improves efficiency.

How does the JVOP-180 display information to the user?

The JVOP-180 features a 5-line liquid crystal display (LCD). Each line can show up to 20 characters, providing clear visibility of parameters, status messages, and error codes.

This multi-line display allows users to view multiple critical data points simultaneously. This context is essential for understanding the drive's operating state and making informed adjustments.

The combination of the LCD and the 17-key keypad forms a straightforward navigation system. Users can easily scroll through menus and select options to access the desired information.

What are the operating temperature limitations for the JVOP-180?

The Yaskawa JVOP-180 Portable Handy Operator is designed to operate within a temperature range of 0 to 50 degrees Celsius. This specification ensures reliable performance in typical industrial environments.

Exposing the device to temperatures outside this range can affect its functionality and potentially cause permanent damage. It's important to consider ambient conditions during installation and operation.

Proper ventilation and avoiding direct sunlight or proximity to heat sources are recommended to maintain the JVOP-180 within its specified operating temperature limits.

Can I program complex motion control sequences using the JVOP-180?

While the JVOP-180 is excellent for configuring standard drive parameters, it is primarily an operator interface for basic to intermediate control functions. Complex, high-speed motion control sequences often require more advanced Yaskawa controllers or software.

The JVOP-180 allows for setting speed references, acceleration/deceleration ramps, and basic I/O configurations. It’s ideal for variable speed applications like pumps, fans, and conveyors.

For advanced applications involving precise positioning or multi-axis synchronization, consider Yaskawa's servo drives and dedicated motion controllers, which offer greater programming flexibility.

How does the JVOP-180 contribute to system reliability?

The JVOP-180 enhances system reliability by enabling precise parameter setting and real-time monitoring. Accurate configuration of motor data, protection limits, and operational profiles prevents drive faults.

Its ability to display error codes quickly helps in rapid troubleshooting. This allows maintenance personnel to identify and resolve issues before they lead to system failure or production stoppages.

By facilitating optimal performance tuning, the JVOP-180 ensures the drive operates within safe and efficient limits. This proactive approach minimizes stress on the motor and drive components, extending their lifespan.

Is the JVOP-180 compatible with older Yaskawa drive models?

Compatibility with older Yaskawa drive models can vary. While Yaskawa aims for backward compatibility where feasible, it's crucial to verify specific model support.

Older drive series might use different communication protocols or physical connectors. Always cross-reference the JVOP-180's capabilities with the documentation for your specific older Yaskawa drive.

For very old or discontinued drive models, an adapter or a different operator panel might be necessary. Contacting Yaskawa support or consulting their legacy product information is advisable.