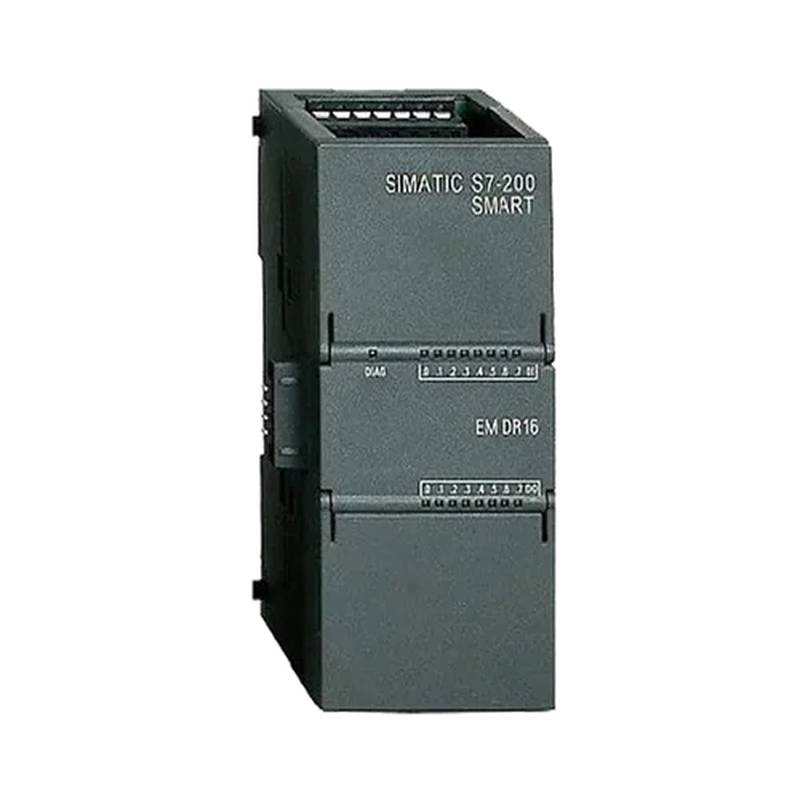

The Siemens 6ES7288-2DR16-0AA0 is a high-performance, industrial-grade relay output module designed to enhance automation control systems with its robust capabilities and reliability. This module offers a substantial number of digital outputs, ensuring broad connectivity for diverse industrial applications. Its advanced design facilitates seamless integration into Siemens' extensive automation portfolio, providing users with a powerful solution for managing complex operational demands.

| Feature | Specification |

| :-------------------- | :---------------------------------------------- |

| Product Type | Digital Output Module |

| Module Name | SIMATIC ET 200SP |

| Order Number | 6ES7288-2DR16-0AA0 |

| Number of Outputs | 16 Relay Outputs |

| Output Voltage Range | 24-230 V AC/DC |

| Switching Current | 2 A per channel |

| Isolation | Yes, between groups and backplane |

| Communication Interface | IM 155-6 PN (required, not included) |

| Temperature Range | -20°C to +60°C |

| Ingress Protection | IP20 |

| Dimensions (WxHxD) | 35.5 mm x 119.5 mm x 54 mm |

| Mounting | DIN rail |

| System Compatibility | SIMATIC S7-1200, S7-1500, ET 200SP |

Core Features & Market Positioning

The Siemens 6ES7288-2DR16-0AA0 distinguishes itself through its high density of 16 relay outputs, offering significant space and cost savings compared to deploying multiple lower-density modules. Its ability to handle a wide voltage range (24-230 V AC/DC) and a robust 2A per channel switching current makes it exceptionally versatile for controlling various actuators, contactors, and pilot lights across different voltage systems. This module is positioned as a premium solution within the SIMATIC ET 200SP distributed I/O system, emphasizing Siemens' commitment to industrial robustness, reliability, and seamless integration within their comprehensive automation ecosystem. Its industrial-grade construction ensures dependable operation in harsh environments, a critical factor for applications demanding high uptime and minimal maintenance.

Key Application Scenarios

This relay output module is ideally suited for a wide array of industrial automation tasks where robust switching capabilities are paramount. It excels in controlling high-power machinery and equipment in manufacturing plants, such as managing conveyor belts, pumps, and motor starters. In building automation, the 6ES7288-2DR16-0AA0 can reliably switch lighting circuits, HVAC systems, and other auxiliary equipment, offering centralized control and monitoring. Furthermore, its suitability for diverse voltage levels makes it a flexible choice for process industries, including water treatment and chemical processing, where controlling a variety of electrical loads is essential for operational efficiency and safety.

Practical System Integration Guidance

Integrating the Siemens 6ES7288-2DR16-0AA0 into a SIMATIC system is streamlined due to its design for the ET 200SP distributed I/O system. The module connects to the backplane via a bus adapter, which is crucial for establishing communication with the central controller (e.g., S7-1500 or S7-1200 CPU). Wiring is straightforward, with clearly labeled terminals for each of the 16 relay outputs, accommodating standard industrial wiring practices. For commissioning, the module is recognized automatically by the TIA Portal engineering software, where its I/O addresses are configured and diagnostic functions are set up. Proper grounding and adherence to voltage/current ratings are essential for safe and reliable operation.

Operation and Risk Mitigation

Operating the Siemens 6ES7288-2DR16-0AA0 requires adherence to electrical safety standards. The module features internal isolation between output groups and from the backplane, enhancing safety and reducing the risk of electrical interference or damage during operation. Users must ensure that the connected loads do not exceed the 2A per channel rating or the overall module capacity to prevent overheating and premature failure. In the event of a fault, diagnostic LEDs on the module provide immediate visual feedback, aiding in rapid troubleshooting. While specific fault codes are typically managed at the controller level, understanding the module's operational status indicators is key to proactive maintenance and risk mitigation.

Scalability & Long-Term Value

The Siemens 6ES7288-2DR16-0AA0 offers significant long-term value through its seamless scalability within the SIMATIC ET 200SP ecosystem. This platform allows for the easy addition of further I/O modules, including digital inputs, analog I/O, and specialized modules, to expand system capabilities as automation needs evolve. Its compatibility with current and future Siemens controllers ensures that investments in this hardware remain relevant. Furthermore, as industries increasingly adopt Industrial Internet of Things (IIoT) solutions, the ET 200SP system's integration capabilities, often facilitated through PROFINET communication, enable the 6ES7288-2DR16-0AA0 to be part of a connected, data-driven industrial environment, enhancing overall operational intelligence and efficiency.

Frequently Asked Questions

What is the primary function of the Siemens 6ES7288-2DR16-0AA0?

This module serves as a robust interface for digital control signals in industrial automation. It provides 16 individual relay outputs to switch higher voltage or current loads.

It allows your central controller to command external devices like motors, lights, or contactors. The relay mechanism offers electrical isolation for enhanced safety and flexibility.

It is designed for high reliability in demanding industrial environments, ensuring consistent performance.

Can the Siemens 6ES7288-2DR16-0AA0 be used with non-Siemens PLCs?

While primarily designed for Siemens SIMATIC systems, it may be possible with extensive custom engineering. This typically involves using a compatible industrial communication gateway or protocol converter.

Such integration requires advanced knowledge of industrial networking and PLC programming. It's generally not a plug-and-play solution outside the Siemens ecosystem.

For optimal performance and support, it is strongly recommended to use this module with Siemens controllers like the S7-1200 or S7-1500.

What is the maximum switching capacity of each relay in the 6ES7288-2DR16-0AA0?

Each individual relay output on this module can handle a maximum switching current of 2 Amperes. This rating is crucial for determining the type and size of loads it can directly control.

It is also important to consider the voltage rating, which allows for operation with 24-230V AC or DC loads. Exceeding these limits can lead to module damage or failure.

Always consult the full technical documentation for specific inductive load considerations and required protection circuitry to ensure longevity.

How do I wire the Siemens 6ES7288-2DR16-0AA0 for a 230V AC load?

Connect your 230V AC supply and the device to be controlled to the appropriate output terminals. Ensure the common terminal for the relevant group is connected to the neutral or common side of your AC supply.

Adhere strictly to electrical codes and safety regulations during wiring. Use appropriate wire gauges for the expected current draw to prevent overheating.

Verify all connections before powering up the system to avoid short circuits or electrical hazards. Proper grounding of the system is also paramount.

What diagnostic information is available for the Siemens 6ES7288-2DR16-0AA0?

The module is equipped with diagnostic LEDs that provide real-time status of each output channel. These LEDs indicate whether an output is active, a fault condition, or a general module status.

More detailed diagnostic information, such as error codes and operational status, can be accessed via the TIA Portal software when connected to the PLC. This allows for sophisticated troubleshooting.

Understanding these diagnostics is key to quickly identifying and resolving issues, minimizing downtime in your automation process.

Is the Siemens 6ES7288-2DR16-0AA0 suitable for hazardous environments?

The 6ES7288-2DR16-0AA0 has an IP20 protection rating, which means it is protected against solid objects larger than 12.5 mm but not against water ingress. It is not inherently designed for hazardous or explosive environments.

For applications in potentially explosive areas (e.g., Zone 1 or Zone 2), specialized intrinsically safe or explosion-proof components are required. These often involve different protection concepts and certifications.

Always ensure that the chosen industrial components comply with the specific environmental and safety regulations of your operating location.

What is the typical operating temperature range for this module?

The Siemens 6ES7288-2DR16-0AA0 is designed to operate reliably within an ambient temperature range of -20°C to +60°C. This wide range makes it suitable for many industrial applications.

However, ensure proper ventilation within the control cabinet to maintain temperatures within the specified limits, especially under heavy load conditions. Overheating can reduce the lifespan of electronic components.

Consider the ambient temperature when selecting a location for the control panel and the I/O modules themselves. Extreme temperatures outside this range can lead to malfunctions.

How does the relay output differ from a transistor output?

Relay outputs use physical contacts to switch power, offering galvanic isolation and the ability to handle AC and DC loads across a wide voltage range. They are typically slower and have a limited number of switching cycles.

Transistor outputs are semiconductor-based, offering faster switching speeds and higher switching frequencies with virtually unlimited lifespan. They are generally limited to DC loads and have lower current handling capabilities.

The choice depends on the application's requirements for speed, voltage type, current capacity, and longevity of switching operations.

What is the role of the bus adapter with the 6ES7288-2DR16-0AA0?

The bus adapter is a critical component that connects the 6ES7288-2DR16-0AA0 module to the ET 200SP backplane. It facilitates communication between the I/O module and the central PLC via the communication interface (IM).

Different bus adapters are available to support various communication protocols, such as PROFINET or PROFIBUS. Selecting the correct bus adapter ensures seamless data exchange within your automation network.

Without the appropriate bus adapter, the I/O module cannot communicate with the controller, rendering it inoperable within the system.

How can I expand the number of outputs if 16 are not enough?

The SIMATIC ET 200SP system is designed for scalability. You can easily add more 6ES7288-2DR16-0AA0 modules or other digital output modules to your station.

Simply slide additional modules onto the ET 200SP backplane, ensuring correct mechanical and electrical connections. The TIA Portal software will then automatically detect and allow configuration of the new modules.

This modular approach provides flexibility to precisely match your application's I/O requirements without over-provisioning hardware.