The Siemens 3RT7025-1AN25 Industrial Motor AC Control Contactor is a robust and reliable component designed for demanding industrial environments. This contactor boasts a 200VAC operating voltage, an 18A current rating, and three normally open (NO) poles, making it ideal for a wide range of motor control applications. Its key advantages lie in its compact design, superior switching capabilities, and Siemens' renowned industrial quality, ensuring dependable operation and extended service life in critical processes.

Product Specifications

| Specification | Value |

| :-------------------- | :------------------------ |

| Product Type | Motor Contactor |

| Manufacturer | Siemens |

| Model Number | 3RT7025-1AN25 |

| Coil Voltage | 200 VAC |

| Rated Operational Current (AC-3) | 18 A |

| Number of NO Contacts | 3 |

| Auxiliary Contacts | Not specified (assumed none included in base unit) |

| Mounting Type | DIN Rail |

| Protection Class | IP20 |

| Ambient Temperature | -25 to +60 °C |

| Certifications | UL, CSA, CE |

Core Features & Market Positioning

The Siemens 3RT7025-1AN25 stands out in the competitive industrial control market due to its robust construction and engineered reliability, hallmarks of the Siemens brand. Its compact footprint allows for high-density panel layouts, a significant advantage in space-constrained industrial cabinets. The contactor's 18A rating at 200VAC, coupled with its three normally open poles, provides ample capacity for controlling medium-sized industrial motors. This product positions itself as a dependable, no-nonsense solution for applications where consistent performance and longevity are paramount, often favored in manufacturing, material handling, and HVAC systems. Siemens' established reputation for quality assurance further solidifies its market standing, offering users peace of mind against premature failures or operational inconsistencies.

Key Application Scenarios

This Siemens 3RT7025-1AN25 industrial motor contactor is extensively employed in direct-on-line (DOL) starting applications for three-phase induction motors. It is a common choice in general manufacturing for controlling conveyor belts, pumps, and fans. In the food and beverage industry, it finds use in process machinery where consistent motor operation is vital. The building automation sector utilizes these contactors for managing HVAC systems, ensuring efficient climate control. Its suitability extends to water treatment plants for pump motor control and material handling equipment such as cranes and elevators.

Practical System Integration Guidance

Integrating the Siemens 3RT7025-1AN25 into an industrial control system is straightforward, leveraging standard electrical wiring practices. For direct-on-line starting, the main power supply (200VAC) is connected to the line-side terminals (L1, L2, L3), and the motor is connected to the load-side terminals (T1, T2, T3). The coil is energized via the control circuit terminals (A1, A2) at the specified 200VAC. Proper termination using appropriate lugs and ensuring secure connections are critical for reliable operation and safety. Overload protection, typically provided by a Siemens 3RU overload relay or a solid-state motor protection relay, should be wired in series with the contactor's power circuit to safeguard the motor against overcurrent conditions.

Operation and Risk Mitigation

Safe operation of the Siemens 3RT7025-1AN25 requires adherence to electrical safety standards and proper commissioning procedures. Before energizing, verify all wiring is correct and secure, and that the ambient temperature remains within operational limits. Ensure the contactor is rated for the motor's full load current and starting characteristics. Overloading the contactor beyond its 18A AC-3 rating can lead to premature contact welding or coil burnout. In the event of erratic operation or failure to energize, check the control voltage supply to the coil (A1, A2) and ensure it is stable at 200VAC. A common troubleshooting step is to visually inspect contacts for signs of pitting or damage.

Scalability & Long-Term Value

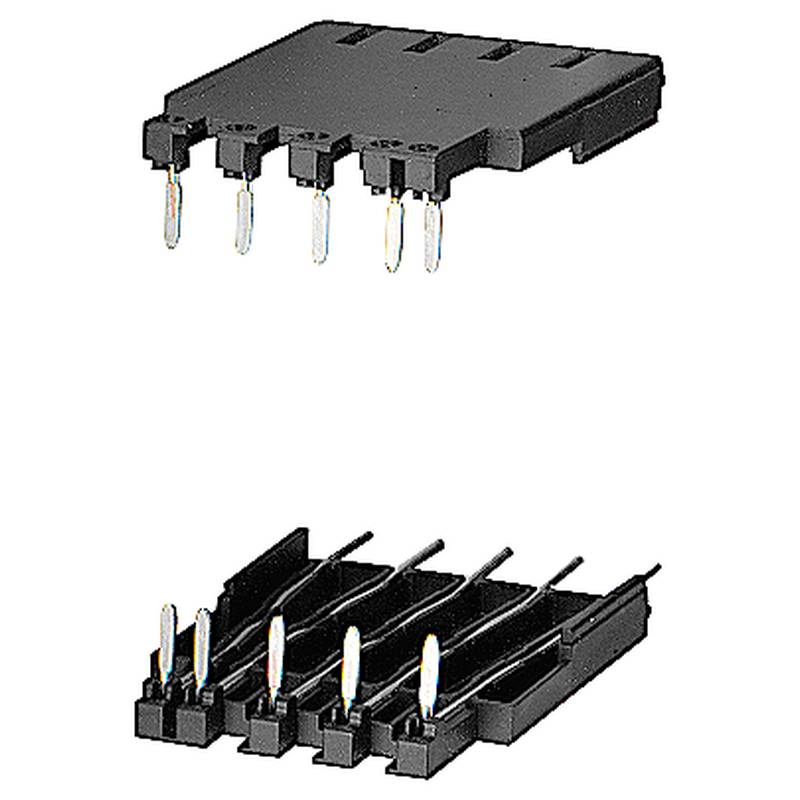

The Siemens 3RT7025-1AN25 offers inherent scalability through its compatibility with a broad range of Siemens industrial automation components. It can be seamlessly integrated into existing PLC-controlled systems, allowing for remote operation and monitoring. For future upgrades, this contactor can be part of a larger system that incorporates advanced diagnostics, predictive maintenance, or even IIoT integration, where its operational status can be communicated to cloud-based platforms for analysis. Its modular design also allows for the addition of auxiliary contact blocks (if supported by specific variants not detailed here) for feedback signaling or interlock functions, enhancing system complexity and capability without replacing the core contactor.

Frequently Asked Questions

What is the maximum voltage for the Siemens 3RT7025-1AN25?

The Siemens 3RT7025-1AN25 is designed for a coil voltage of 200VAC. This is the specific voltage required to energize the contactor's coil and enable it to close the main power contacts. It is crucial to supply the correct voltage to the coil terminals (A1, A2) for proper operation.

The power contacts are rated for general use at various industrial voltages, with the 18A rating typically specified at AC-3 duty, which implies motor control. Always consult the full datasheet for voltage limits on the main power circuit if operating at voltages other than the specified control voltage standard.

Ensuring the coil voltage matches the control power available in your system prevents coil damage and ensures reliable switching. Using a step-down transformer might be necessary if your control voltage differs significantly from 200VAC.

How do I wire the Siemens 3RT7025-1AN25 for a three-phase motor?

For a three-phase motor, connect the incoming L1, L2, and L3 power lines to the top terminals of the 3RT7025-1AN25. Then, connect the motor leads (T1, T2, T3) to the corresponding bottom terminals of the contactor. The coil is wired to A1 and A2 terminals using your 200VAC control circuit power.

Ensure you use appropriately sized conductors and terminals for both the power and control circuits to meet electrical codes and ensure safe, reliable connections. Proper torque on terminal screws is essential.

Always incorporate overload protection, such as a Siemens 3RU overload relay, wired in series with the power circuit, to protect the motor from overcurrent conditions. This often involves connecting the overload relay's sensing elements between the contactor's load terminals and the motor.

What does 18A 3NO mean for this Siemens contactor?

The "18A" signifies the rated operational current the contactor can reliably switch under AC-3 duty, which is typical for motor control applications. This means it can handle 18 amperes continuously for motor loads.

"3NO" indicates that the contactor is equipped with three normally open (NO) auxiliary contacts. These contacts are closed when the main contactor coil is energized and open when the coil is de-energized, providing signaling or interlocking capabilities.

This configuration is standard for directly switching a three-phase motor, where each phase is controlled by a separate NO contact. The three NO contacts ensure all three phases of the motor are connected to power simultaneously when the contactor is activated.