The AUBO-i20 collaborative robot redefines automation with its robust payload capacity and extended reach, designed for demanding industrial tasks. Boasting a 20kg maximum payload and an impressive 1650mm working radius, this cobot seamlessly integrates into diverse manufacturing environments. Its intuitive programming, advanced safety features, and energy-efficient design make it a superior choice for enhancing productivity and operational flexibility. Key technical specifications include a ±0.03mm repeatability, a maximum joint speed of 200°/s, and a lightweight robotic arm construction.

Product Specifications

| Parameter | Value |

| :--------------------- | :------------- |

| Payload | 20 kg |

| Reach | 1650 mm |

| Repeatability | ±0.03 mm |

| Max. Joint Speed | 200°/s |

| Degrees of Freedom | 6 |

| IP Rating | IP54 |

| Operating Temperature | 5-45°C |

| Power Consumption | < 800 W |

| Weight (Robot Arm) | 75 kg |

| Mounting | Floor, Wall, Ceiling |

| Communication | Ethernet, Modbus TCP |

Core Features & Market Positioning

The AUBO-i20 collaborative robot distinguishes itself through its exceptional payload-to-weight ratio and extensive reach, enabling it to handle substantial loads over significant distances. This capability positions it as an ideal solution for applications previously requiring larger, more complex industrial robots. AUBO's commitment to user-friendly operation is evident in its intuitive graphical programming interface, reducing the barrier to entry for automation. Furthermore, the cobot's advanced safety system, compliant with ISO 10218 and ISO/TS 15066, allows for direct human-robot collaboration, a critical differentiator in modern manufacturing settings.

Key Application Scenarios

This versatile collaborative robot excels in a wide array of industrial applications. In material handling, it efficiently manages palletizing, de-palletizing, and machine tending tasks, even with heavier components. Its precision makes it suitable for intricate assembly processes where consistent accuracy is paramount. The AUBO-i20 is also well-suited for inspection and quality control, providing reliable data capture. In the logistics sector, it can streamline order picking and sorting operations. Its robust payload and reach also make it a strong contender for welding and dispensing applications requiring a consistent path and force.

Practical System Integration Guidance

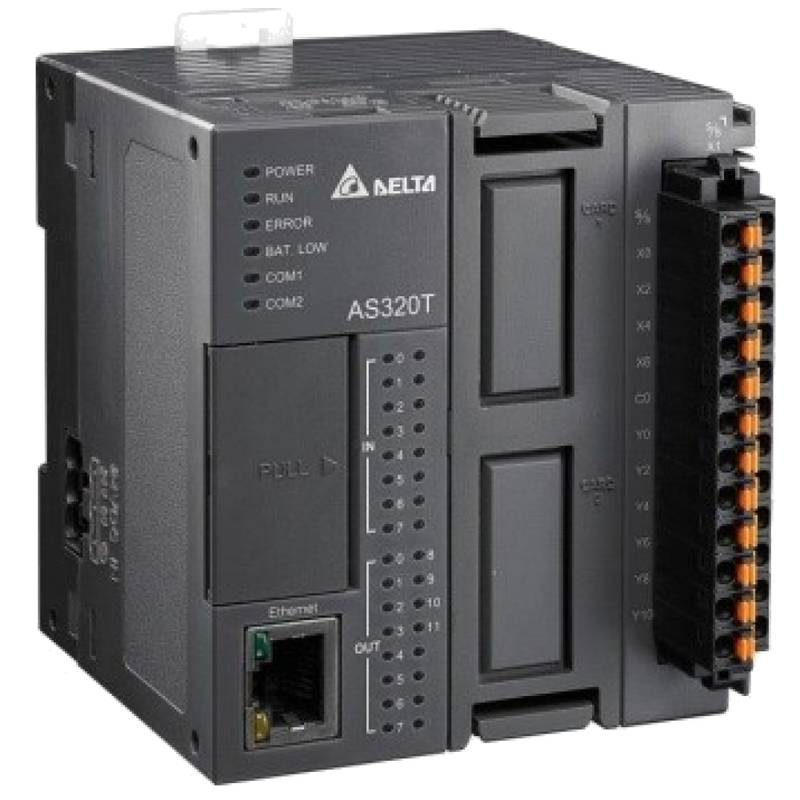

Integrating the AUBO-i20 into existing production lines is streamlined due to its flexible mounting options, including floor, wall, and ceiling configurations. The robot controller features standard Ethernet and Modbus TCP communication ports, facilitating easy connection to PLCs and other industrial network devices. Wiring for power and safety signals is designed for straightforward implementation. Initial commissioning involves a guided setup process through the teach pendant or PC-based software, allowing users to define work zones, tool orientations, and basic motion paths.

Operation and Risk Mitigation

Operating the AUBO-i20 prioritizes safety and ease of use. Its collaborative nature relies on advanced sensors and algorithms that enable it to detect human presence and automatically slow down or stop when necessary, adhering to safety standards. Common troubleshooting often involves checking payload balance, joint limits, and ensuring proper communication setup. Error codes are typically displayed on the teach pendant, with clear documentation available for diagnosing and resolving issues related to motor faults, sensor errors, or communication interruptions.

Scalability & Long-Term Value

The AUBO-i20 collaborative robot offers significant long-term value through its inherent scalability and compatibility. Its modular design allows for future upgrades and integration with a wider ecosystem of automation components. The cobot is designed to interface with Industrial Internet of Things (IIoT) platforms, enabling remote monitoring, data analytics, and predictive maintenance. This forward-looking architecture ensures that the AUBO-i20 can adapt to evolving production demands and technological advancements, providing a sustainable return on investment.

Frequently Asked Questions

What is the maximum payload of the AUBO-i20?

The AUBO-i20 collaborative robot is engineered to handle a substantial maximum payload of 20 kilograms. This capacity makes it suitable for lifting and manipulating heavier parts or tools. It can efficiently manage tasks like palletizing or transferring larger components.

This impressive payload capability is a key feature for industries dealing with heavier items. It allows for greater flexibility in application design. You can confidently automate processes that require moving significant weight.

Its 20kg capacity ensures that the robot can be a central piece in many automated work cells. This reduces the need for multiple, smaller robots or manual intervention for heavier tasks.

What is the working reach of the AUBO-i20?

The AUBO-i20 collaborative robot offers an extensive working reach of 1650 millimeters. This broad operational radius allows the robot to cover a large workspace. It can access machines or work areas from various positions.

This long reach is advantageous for tasks requiring the robot to operate across a wider area. It's beneficial for applications like machine tending or complex assembly. It enables greater flexibility in cell layout.

With a 1650mm reach, the AUBO-i20 can effectively service multiple stations or machines. This maximizes its utility and reduces the need for extensive repositioning. It enhances overall cycle times.

What industries can benefit from the AUBO-i20?

The AUBO-i20 collaborative robot serves a wide range of industries. Manufacturing sectors like automotive, electronics, and general manufacturing are prime beneficiaries. Its versatility also extends to logistics and warehousing operations.

Specific applications include material handling, assembly, quality inspection, and palletizing. Industries requiring high precision and repeatability also find it valuable. It's designed for adaptable automation.

Logistics companies can use it for order picking or sorting. It's also applicable in sectors needing consistent dispensing or welding. Its robust capabilities make it a general-purpose automation solution.

How is the AUBO-i20 programmed?

Programming the AUBO-i20 is designed for user-friendliness. It utilizes an intuitive graphical interface accessible via a teach pendant or PC software. Users can easily create and modify robot paths through direct teaching or a visual drag-and-drop system.

The programming environment supports simple motion commands, logic operations, and I/O control. This allows for the creation of complex tasks without extensive coding knowledge. It simplifies automation deployment.

Advanced users can also leverage script-based programming for more intricate functions. The system is designed to accommodate varying levels of user expertise. It ensures flexibility in automation strategies.

What are the safety features of the AUBO-i20?

The AUBO-i20 collaborative robot is equipped with advanced safety mechanisms. It adheres to international safety standards like ISO 10218 and ISO/TS 15066. Built-in sensors detect human proximity and can initiate speed reduction or a full stop.

It includes features like power and force limitation, as well as collision detection. These enable safe human-robot interaction in shared workspaces. The robot is designed for collaborative environments.

The safety system ensures that the robot can operate alongside human workers without requiring extensive safety caging in many applications. This enhances operational flexibility and efficiency. It prioritizes worker well-being.

What is the repeatability of the AUBO-i20?

The AUBO-i20 collaborative robot offers a high degree of precision with a repeatability of ±0.03 mm. This ensures that the robot can return to programmed positions with exceptional accuracy time after time. Such precision is critical for repetitive tasks.

This level of repeatability is essential for applications like delicate assembly, precise placement, or automated inspection. It guarantees consistent performance throughout the production cycle. It minimizes errors in intricate operations.

The ±0.03 mm repeatability ensures quality control and reduces scrap rates. It is a key specification for manufacturing processes where exact positioning is paramount. This makes it reliable for demanding tasks.

What is the IP rating of the AUBO-i20?

The AUBO-i20 collaborative robot has an IP54 rating. This indicates it offers protection against dust ingress to a limited extent. It also provides defense against splashing water from any direction.

This IP54 rating makes the robot suitable for many industrial environments. It can withstand typical factory conditions, including some dust and moisture. It ensures reliable operation in common settings.

While not fully waterproof, the IP54 rating allows the AUBO-i20 to operate effectively in most manufacturing facilities. It offers a good balance of protection for general industrial automation. It is suitable for typical assembly lines.

How can the AUBO-i20 be integrated into existing systems?

Integration is simplified with standard communication protocols like Ethernet and Modbus TCP. This allows easy connection to PLCs, SCADA systems, and other factory automation equipment. The controller is designed for network compatibility.

Flexible mounting options (floor, wall, ceiling) allow it to fit into various cell layouts. This reduces the need for significant infrastructure changes. Installation is adaptable to space constraints.

Wiring for power and safety is designed for straightforward implementation. The robot's open architecture supports integration with third-party end-effectors and vision systems. It enhances adaptability.

What is the power consumption of the AUBO-i20?

The AUBO-i20 collaborative robot features an energy-efficient design with a power consumption of less than 800 Watts. This low power draw contributes to reduced operating costs and a smaller environmental footprint. It is ideal for sustainable manufacturing.

Its efficient operation makes it suitable for applications where energy savings are a priority. The robot utilizes power effectively during its operation. This keeps utility expenses down.

The < 800W consumption aligns with modern demands for greener automation solutions. It provides significant robotic capability with minimal energy impact. This makes it an economical choice.

What are common troubleshooting steps for the AUBO-i20?

Common troubleshooting involves verifying payload balance and ensuring the robot arm is not exceeding its limits. Check all communication connections and ensure the teach pendant is properly connected. Review error messages on the controller.

Pay attention to joint limits and speeds, as exceeding these can trigger faults. Ensure end-effector wiring and pneumatic lines are secure and correctly connected to prevent operational issues. Software updates should also be checked.

If persistent issues arise, consult the detailed error code list in the AUBO-i20 manual. For complex problems, contacting AUBO support or a certified integrator is recommended. Proper maintenance is key.