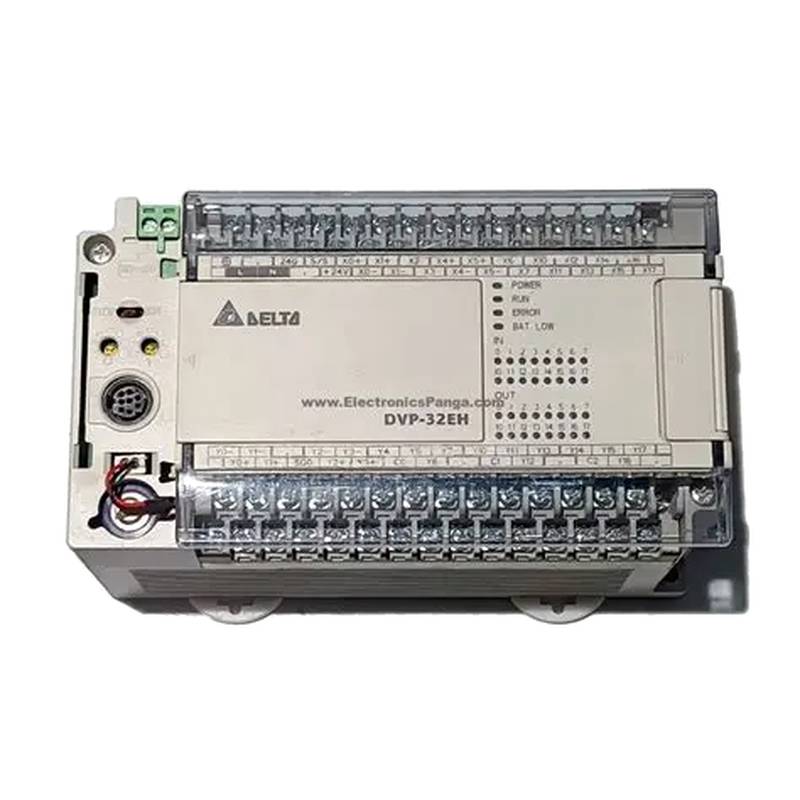

The Delta DVP32EH00M3 stands as a robust 32-point CPU Main Unit, engineered for demanding industrial automation control applications. This PLC (Programmable Logic Controller) unit offers exceptional performance, reliability, and flexibility, making it a cornerstone for modern manufacturing and process control systems. Its core advantages lie in its high-speed processing capabilities, extensive I/O capacity, and seamless integration potential. Key technical parameters include a substantial program memory, a broad operating temperature range, and efficient power consumption, ensuring stable operation in diverse industrial environments.

Product Specifications

| Feature | Specification |

| :---------------- | :------------------------------------------ |

| Model | DVP32EH00M3 |

| CPU Type | 32-point CPU Main Unit |

| Digital Input | 16 points |

| Digital Output | 16 points (Relay Type) |

| Program Capacity | 16k steps |

| Data Registers | 10k words |

| Communication Ports| Built-in RS-232, RS-485 |

| Power Supply | 100-240VAC, 50/60Hz |

| Operating Temp. | 0°C to 50°C |

| Dimensions (WxHxD)| 140mm x 90mm x 60mm |

Core Features & Market Positioning

The Delta DVP32EH00M3 distinguishes itself through its high-speed execution, crucial for time-sensitive automation tasks. Its extensive point count (32 I/O) on a compact main unit reduces panel space and wiring complexity, a significant advantage in cost-conscious projects. Delta's established reputation for reliable industrial automation hardware further solidifies its market position, offering a compelling balance of performance and value. The unit supports a wide array of communication protocols, enabling facile integration into existing SCADA and HMI systems, and positioning it as a versatile solution for various industry needs.

Key Application Scenarios

This 32-point CPU unit is ideally suited for a broad spectrum of industrial applications. It excels in controlling machinery in discrete manufacturing, such as assembly lines, packaging equipment, and material handling systems. In process industries, it can manage basic batch control, fluid handling, and temperature regulation. Its robust design and comprehensive I/O make it a practical choice for building automation, water treatment plants, and HVAC control systems where reliable, straightforward automation is paramount. The DVP32EH00M3 is particularly relevant for users searching for "Delta PLC for machine control" or "industrial automation 32 I/O controller."

Practical System Integration Guidance

Integrating the Delta DVP32EH00M3 involves careful wiring and programming. The digital inputs and outputs are clearly labeled for straightforward connection to sensors, actuators, and control devices. For communication, users typically employ RS-232 or RS-485 ports to connect with HMIs, other PLCs, or supervisory systems, often utilizing Modbus RTU protocol. Programming is typically done using Delta's proprietary ISPSoft software, which supports ladder logic, instruction list, and structured text, allowing engineers to develop control logic efficiently. Proper grounding and power supply considerations are essential for optimal performance and longevity.

Operation and Risk Mitigation

Operating the Delta DVP32EH00M3 requires adherence to standard industrial safety practices. Ensure that power is disconnected before performing any wiring or maintenance. Avoid exposing the unit to extreme temperatures, humidity, or conductive dust. Common troubleshooting often involves checking input/output status via the programming software or status LEDs on the unit. While specific fault codes depend on the application logic, common issues can arise from incorrect wiring, power fluctuations, or program errors. Users should consult the official Delta documentation for detailed error code explanations and preventative maintenance guidelines to mitigate risks.

Scalability & Long-Term Value

The Delta DVP32EH00M3 offers excellent scalability through its ability to expand I/O capacity using Delta's extensive range of expansion modules. This allows systems to grow with evolving production needs without requiring a complete PLC replacement. Compatibility with Delta's broader automation ecosystem, including HMIs, servo drives, and inverters, provides a unified platform for advanced control solutions. Furthermore, its support for modern communication protocols facilitates integration into Industrial Internet of Things (IIoT) frameworks, enabling data acquisition for performance monitoring and predictive maintenance, thereby enhancing long-term operational value.

Frequently Asked Questions

1. What are the primary advantages of the Delta DVP32EH00M3 PLC?

The Delta DVP32EH00M3 offers high-speed processing for critical applications. It features a generous 32-point I/O count on a compact main unit. Delta's reputation for reliability in industrial automation provides users with confidence.

This PLC is cost-effective for many automation tasks. Its robust design ensures stable operation in challenging environments. Users benefit from its ease of integration with other Delta products.

The unit supports flexible communication options, enhancing connectivity. Its scalability via expansion modules adds long-term value to automated systems.

2. How do I connect sensors and actuators to the DVP32EH00M3's digital I/O?

Digital inputs on the DVP32EH00M3 receive signals from sensors like proximity switches or pushbuttons. Ensure correct voltage levels and polarity are maintained during wiring. Connect the common terminal of the sensor to the appropriate PLC common.

Digital outputs can control devices such as relays, indicator lights, or motor starters. Pay close attention to the output type (relay or transistor) and its voltage/current ratings. Overloading outputs can lead to failure.

Always refer to the DVP32EH00M3's wiring diagrams in the user manual for precise connection details. Proper grounding is critical for signal integrity and safety.

3. What programming software is used for the Delta DVP32EH00M3?

The primary programming software for the Delta DVP32EH00M3 is ISPSoft. This integrated development environment supports multiple programming languages, including ladder logic diagrams (LD).

Engineers can also utilize instruction list (IL) and structured text (ST) within ISPSoft. The software provides tools for simulation, debugging, and project management.

Users must download and install ISPSoft from Delta's official website. Ensure you have the correct version compatible with the DVP32EH00M3 firmware.

4. Can the Delta DVP32EH00M3 communicate with other devices like HMIs or SCADA systems?

Yes, the DVP32EH00M3 is equipped with built-in RS-232 and RS-485 communication ports. These ports are ideal for connecting to Human Machine Interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems.

The unit commonly uses the Modbus RTU protocol for serial communication. This allows for seamless data exchange with a wide range of third-party devices and software platforms.

Configuration of communication parameters, such as baud rate and parity, is done within the PLC programming software. This ensures reliable data transfer between the PLC and other connected systems.

5. What is the program memory capacity of the DVP32EH00M3?

The Delta DVP32EH00M3 CPU Main Unit comes with a program memory capacity of 16k steps. This capacity is sufficient for a wide range of complex automation control logic.

This allows for detailed sequencing, intricate logic, and the implementation of advanced functions required in industrial automation. It provides ample space for user programs and system instructions.

While 16k steps is substantial, complex applications may require careful optimization of code to fit within this limit or consideration of expansion modules for larger projects.

6. How does the Delta DVP32EH00M3 handle power fluctuations and environmental conditions?

The DVP32EH00M3 is designed to operate within a specific voltage range of 100-240VAC, 50/60Hz. It incorporates internal power conditioning to mitigate minor fluctuations.

For extreme power variations or noise, external power conditioners or UPS systems are recommended. The unit's operating temperature range is 0°C to 50°C, and it should be protected from direct sunlight and moisture.

Ensuring proper ventilation around the PLC is crucial to prevent overheating. Adhering to these environmental guidelines maintains the unit's reliability and lifespan.

7. What are common troubleshooting steps for the DVP32EH00M3?

Begin by verifying power supply stability and correct wiring connections to all I/O points. Check the status LEDs on the PLC for any abnormal indications.

Use the ISPSoft software to monitor program execution and input/output status in real-time. Look for logical errors in the ladder logic or program.

Consult the DVP32EH00M3 user manual for specific error codes or diagnostic information. Ensure the firmware is up-to-date and compatible with your project.

8. How can I expand the I/O capabilities of the DVP32EH00M3?

The DVP32EH00M3 supports Delta's range of expansion modules. These modules can add more digital or analog inputs and outputs to the system.

Connection of expansion modules is typically done via a dedicated communication bus on the side of the PLC. Ensure module compatibility and adhere to the maximum number of expansion modules allowed per CPU.

Carefully plan your expansion strategy based on current and future I/O requirements to ensure seamless system integration and scalability.

9. What is the typical response time or scan time for the DVP32EH00M3?

The Delta DVP32EH00M3 features a high-speed CPU that offers efficient scan times. While specific scan times vary based on program complexity and I/O configuration, it is optimized for performance in demanding applications.

Delta's EH series PLCs are known for their rapid execution speeds, crucial for applications requiring quick responses, such as high-speed motion control or intricate sequencing. Expect scan times in the sub-millisecond range for simple programs.

For precise performance metrics, users should refer to Delta's technical documentation or perform benchmarking tests with their specific application logic within the ISPSoft simulation environment.

10. Is the Delta DVP32EH00M3 suitable for IIoT integration?

Yes, the DVP32EH00M3 can be integrated into IIoT solutions. Its communication ports (RS-232/RS-485) can connect to gateways or edge devices that facilitate data acquisition and cloud connectivity.

By leveraging protocols like Modbus TCP/IP via an appropriate gateway, the PLC data can be sent to IIoT platforms for analysis, monitoring, and remote management. This enables smart manufacturing capabilities.

Integration allows for advanced features such as predictive maintenance, remote diagnostics, and process optimization, enhancing the overall value and intelligence of the automated system.