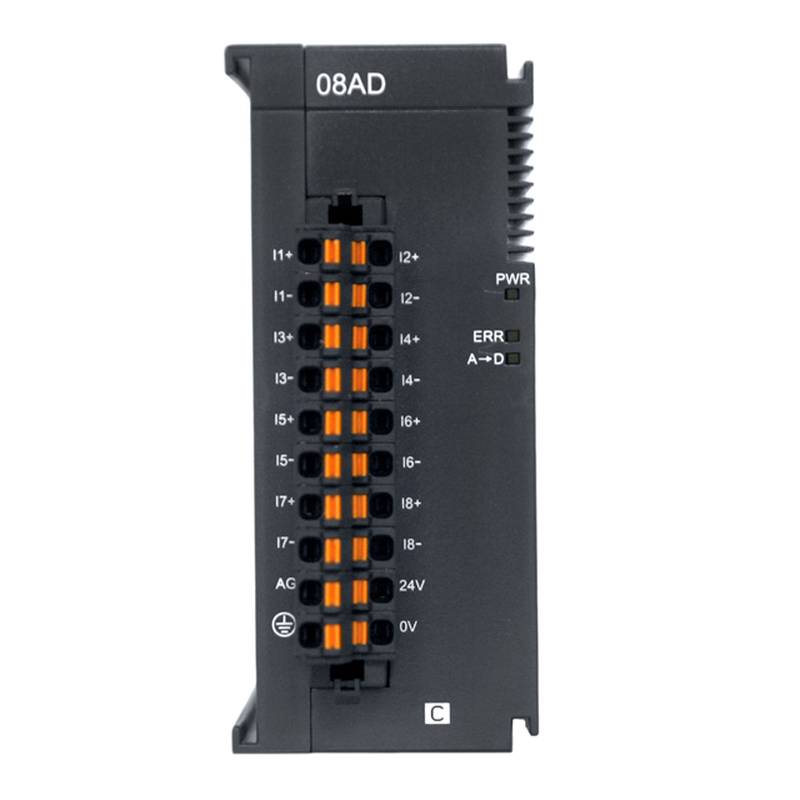

The Delta AS08AD-C is an 8-channel enhanced high-precision analog input module designed for robust industrial automation applications. It offers a 16-bit hardware resolution, ensuring precise signal acquisition, and a rapid 2ms conversion time per channel, crucial for real-time control systems. This module supports multiple current input modes, including 0/4–20mA and -20 to +20mA, providing flexibility for various sensor integrations. Key advantages include its non-backplane design for direct DIN rail mounting and plug-in, screwless terminals that simplify wiring and maintenance, enhancing overall operational efficiency and reducing downtime.

Product Specifications

| Feature | Specification |

| :--------------------- | :------------------------------------------------- |

| Manufacturer | Delta |

| Product Number | AS08AD-C |

| Module Type | 8-channel Analog Input Module |

| Analog Input Channels | 8 |

| Input Signal Type | Current (0/4–20mA, -20 to +20mA) |

| Hardware Resolution | 16-bit |

| Conversion Time | 2ms/channel |

| Supply Voltage | 24 VDC |

| Power Consumption | 1.2W / 2.5W (Internal) |

| Mounting Type | Direct DIN rail mounting (Plug-in) |

| Terminal Type | Screwless (push-in) removable terminal blocks |

| Dimensions (H x W x D) | 88 mm x 35 mm x 95 mm |

| Operating Temperature | Not specified in provided data |

| Storage Temperature | Not specified in provided data |

| IP Rating | IP20 |

| Compatibility | Delta AS Series PLC |

| Wire Break Detection | Supported (1-5V, 4-20mA modes) |

Core Features & Market Positioning

The Delta AS08AD-C distinguishes itself within the industrial automation market through its high precision and enhanced capabilities, positioning it as a premium analog input solution. Its 16-bit resolution offers superior accuracy over standard 12-bit modules, making it ideal for applications demanding meticulous measurement, such as in sophisticated process control or quality inspection systems. The rapid 2ms conversion time per channel is a significant competitive advantage, enabling faster response times and improved dynamic control for high-speed machinery. Furthermore, the module's plug-in, screwless terminals represent a user-centric design choice, reducing installation complexity and maintenance overhead, which translates to lower total cost of ownership for end-users. This combination of performance, ease of use, and reliability aligns with Delta's reputation for delivering advanced yet practical automation components.

Key Application Scenarios

The Delta AS08AD-C analog input module finds extensive utility across a broad spectrum of industrial sectors where precise signal acquisition is paramount. Its 8-channel capacity makes it highly efficient for consolidating multiple sensor inputs into a single PLC controller. Common applications include:

Electronics Manufacturing: High-precision monitoring of current signals from testing equipment, power supplies, or process parameters requiring tight tolerances. Food and Beverage Processing: Accurate measurement of flow rates, pressure, and temperature for quality control and process optimization in complex production lines. Textile Machinery: Precise control of motor speeds and actuator positions where subtle variations in analog signals dictate product quality and operational efficiency. Packaging Equipment: Real-time monitoring of sensor feedback for filling, sealing, and labeling processes, ensuring consistent product output and minimizing waste. Automated Equipment: Integration into various custom-built machinery for diverse tasks, from labeling to precise material handling, benefiting from its versatile current input capabilities. Process & Control Industries: General-purpose analog signal acquisition in chemical plants, water treatment facilities, and power generation, where reliable data is critical for operational stability.

Practical System Integration Guidance

Integrating the Delta AS08AD-C into an industrial control system is streamlined due to its design and compatibility with the Delta AS Series PLC. The module features direct DIN rail mounting and utilizes plug-in, screwless (push-in) terminals, eliminating the need for screw-tightening and simplifying wiring considerably. This push-in connection method ensures secure connections and allows for quick module replacement or addition without extensive rewiring. For system configuration, the AS08AD-C is programmed and configured using Delta's ISPSoft software, specifically within the HWCONFIG utility. Users can manually set parameters such as input mode (e.g., 4-20mA) and perform channel calibration via offset adjustments through the software interface. Ensuring proper 24 VDC power supply and correct wiring of the analog signal source to the designated input terminals is fundamental for successful operation. Compatibility is primarily with the Delta AS Series CPUs, allowing seamless expansion of I/O capabilities.

Operation and Risk Mitigation

Operating the Delta AS08AD-C module requires adherence to standard industrial safety practices and careful attention to its specifications. The module is designed for use within a 24 VDC power supply system; incorrect voltage application can lead to module damage. Its IP20 rating indicates it is protected against solid objects larger than 12.5mm and dripping water, necessitating installation in a control cabinet or protected enclosure to prevent ingress of dust, moisture, or foreign objects. Troubleshooting common issues often involves verifying power supply, checking analog signal wiring integrity, and confirming correct configuration within the PLC programming software. While specific error codes are not detailed in the provided snippets, wire break detection for 1-5V and 4-20mA modes is a built-in feature that aids in diagnosing signal interruptions, enhancing operational reliability and reducing potential system failures. Always consult the official Delta AS Series Module Manual for comprehensive operational guidelines and troubleshooting procedures.

Scalability & Long-Term Value

The Delta AS08AD-C module offers significant scalability and long-term value as part of the Delta AS Series PLC ecosystem. The AS Series architecture supports up to 32 extension modules or a total of 1,024 inputs/outputs, allowing systems to grow substantially from a compact base configuration. This inherent scalability means that as application requirements expand, additional I/O modules, including more analog inputs, digital I/O, or specialized modules like temperature or load cell inputs, can be seamlessly added. Compatibility with Delta's robust AS Series CPUs and network communication protocols like CANopen and EtherNet/IP ensures that the AS08AD-C can integrate into modern, connected industrial environments, including future IIoT and Industry 4.0 initiatives. This forward-looking design ensures that investments in Delta automation hardware retain their value and can adapt to evolving industrial demands.

*

Frequently Asked Questions (FAQs)

1. What are the primary advantages of using the Delta AS08AD-C module?

The Delta AS08AD-C offers 16-bit precision for accurate data acquisition. Its 8 channels provide high input density. It boasts a fast 2ms conversion time per channel for real-time applications. Enhanced features include wire break detection for improved diagnostics.

This module simplifies installation with its plug-in, screwless terminals. It also features a non-backplane design for direct DIN rail mounting. These elements reduce wiring complexity and maintenance time, lowering operational costs.

Its integration with the Delta AS Series PLC ensures a cohesive and expandable automation solution. This makes it suitable for diverse industrial needs requiring reliable analog signal processing.

2. Can the Delta AS08AD-C module handle different types of analog current signals?

Yes, the AS08AD-C module supports multiple industrial current input ranges. It is configurable for 0-20mA and 4-20mA standard signals. It also supports bipolar ranges like -20 to +20mA.

This flexibility allows it to interface with a wide array of sensors and transmitters commonly used in industrial settings. Users can select the appropriate range during system configuration via software.

By supporting these varied current inputs, the module ensures broad compatibility and suitability for many different process control applications without needing specialized modules.

3. What is the conversion time of the Delta AS08AD-C and why is it important?

The Delta AS08AD-C module features a conversion time of 2 milliseconds per channel. This is a critical parameter for applications requiring rapid response to changing process variables.

A faster conversion time means the PLC receives updated analog data more quickly. This enables more precise closed-loop control and faster reaction to dynamic events on the plant floor.

For high-speed machinery or critical control loops, this 2ms speed is essential for maintaining accuracy, stability, and performance, distinguishing it from slower modules.

4. How is the Delta AS08AD-C module installed and wired?

Installation is straightforward with its direct DIN rail mounting capability. The module slides onto a standard 35mm DIN rail without requiring a backplane.

Wiring is simplified using plug-in, screwless (push-in) terminals. This design eliminates the need for screwdrivers and speeds up connections, reducing installation errors.

Simply strip the wire and insert it into the terminal for a secure connection, facilitating quick setup and maintenance.

5. What PLC series is the Delta AS08AD-C compatible with?

The AS08AD-C is designed specifically for the Delta AS Series PLC. This includes support for AS200 and AS300 series CPUs.

This ensures seamless integration within Delta's modular PLC architecture. It allows for easy expansion of analog input capabilities for these controllers.

Users can expand their AS Series system by adding multiple AS08AD-C modules to meet their specific I/O requirements.

6. What is the resolution of the Delta AS08AD-C module?

The Delta AS08AD-C module features a high hardware resolution of 16 bits. This provides a fine-grained measurement of analog input signals.

A 16-bit resolution offers a significantly higher level of detail compared to standard 12-bit modules. It results in more precise readings and better process control accuracy.

This high resolution is crucial for applications where even small variations in analog signals need to be accurately detected and processed.

7. Does the Delta AS08AD-C have any diagnostic features?

Yes, the AS08AD-C includes built-in wire break detection capabilities. This feature enhances system diagnostics and reliability.

Wire break detection is supported for specific analog signal modes, including 1-5V and 4-20mA. It helps identify signal interruptions quickly.

This diagnostic function alerts operators or the PLC to potential issues, allowing for faster troubleshooting and minimizing downtime.

8. What are the power requirements for the Delta AS08AD-C module?

The Delta AS08AD-C module operates on a standard 24 VDC supply voltage. This is a common power standard in industrial automation.

It draws a relatively low internal power consumption, rated at 1.2W or 2.5W depending on usage. This efficiency contributes to overall system energy management.

Users must ensure a stable and correct 24 VDC power source is provided to the module for reliable operation.

9. What is the physical size and mounting method of the AS08AD-C?

The module has compact dimensions of approximately 88mm (H) x 35mm (W) x 95mm (D). This small footprint saves valuable space in control cabinets.

It is designed for direct mounting onto a standard 35mm industrial DIN rail. This is a common and convenient mounting standard in control panels.

The plug-in design further simplifies installation by allowing modules to be easily added or removed.

10. Where can I find more detailed technical information or documentation for the AS08AD-C?

Comprehensive technical specifications and operational details can be found in the official Delta AS Series Module Manual. This manual is the authoritative source for all module functions.

Datasheets and product catalogs from Delta Electronics or authorized distributors provide overview information, specifications, and application examples. These are typically available for download.

For specific configuration and programming guidance, users should refer to the ISPSoft software documentation and the HWCONFIG utility instructions provided by Delta.