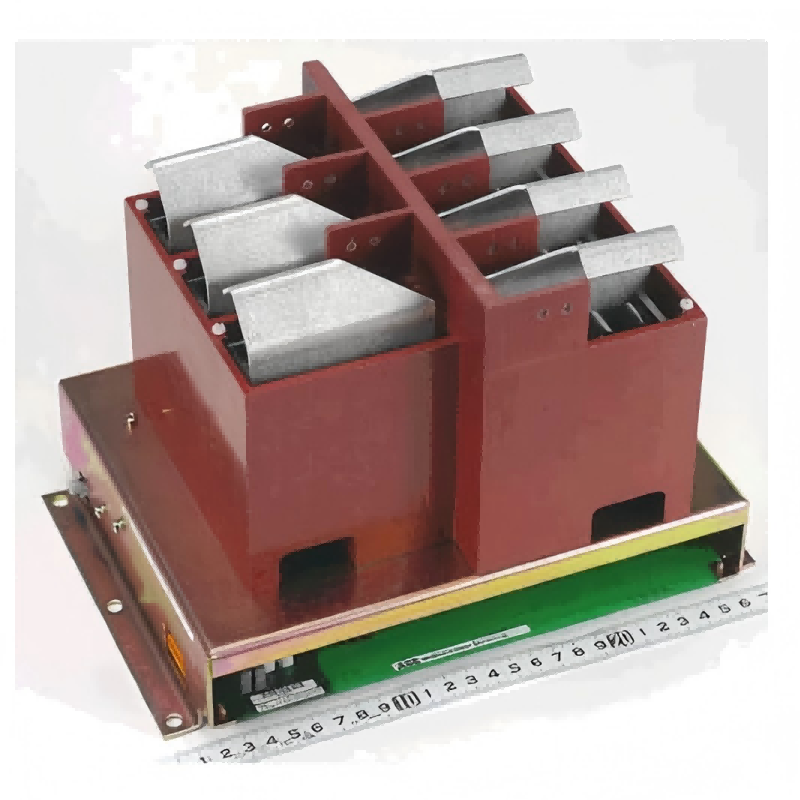

The SIEMENS 6SL5100-0EE21-6AD0 is a 16kW Booksize D-Type Reactor specifically designed for the SINAMICS S220 drive system, operating on a 3-phase, 480V AC supply. This essential component plays a crucial role in optimizing drive performance and system reliability. It functions as a line reactor, effectively limiting line harmonics and protecting the SINAMICS S220 Smart Line Module from potential power quality issues. The D-Type designation signifies its suitability for highly dynamic, intermittent duty cycles with overload capabilities of up to 300%, making it ideal for applications demanding rapid acceleration and deceleration. Its compact "booksize" form factor ensures efficient use of space within control cabinets, a hallmark of modern industrial automation design.

Product Specifications

| Specification | Value |

| :------------------- | :---------------------------------------------------- |

| Manufacturer | Siemens |

| Part Number | 6SL5100-0EE21-6AD0 |

| Product Type | Line Reactor for SINAMICS S220 Smart Line Module |

| Power Rating | 16 kW |

| Input Voltage | 380-480 V 3 AC |

| Form Factor | Booksize D-Type |

| Rated Current | 29 A |

| Weight | 9.00 Kg (approx.) |

| Country of Origin | Germany |

| RoHS Compliance | Device RoHS compliant (environmentally compatible) |

| Standard Delivery Time | 15 Days |

Core Features & Market Positioning

The SIEMENS 6SL5100-0EE21-6AD0 is positioned as a premium component within Siemens' robust SINAMICS drive ecosystem. Its primary advantage lies in its specific design for the SINAMICS S220, ensuring seamless integration and optimized performance. The D-Type reactor's ability to handle high dynamic loads and significant overloads up to 300% differentiates it for demanding applications where precise and powerful motion control is paramount. This feature directly translates to increased machine productivity and longevity. Furthermore, its booksize form factor aligns with the trend towards space-saving solutions in control cabinet design, making it a preferred choice for machine builders and system integrators focused on efficiency and compact integration. Its RoHS compliance also underscores Siemens' commitment to environmental standards.

Key Application Scenarios

This 16kW booksize D-type reactor is indispensable in a variety of industrial automation settings requiring high dynamic performance. It is particularly well-suited for:

Machine Tools: Applications demanding precise and rapid axis movements, such as CNC machines, milling centers, and lathes, benefit from the reactor's ability to manage rapid acceleration and deceleration profiles. Packaging Machinery: High-speed and intermittent operations common in packaging lines, including filling, sealing, and labeling stations, can leverage the D-Type reactor's overload capacity. Material Handling Systems: Automated guided vehicles (AGVs), robotics, and conveyor systems that require frequent starts, stops, and speed changes will experience enhanced performance and reliability. Printing Presses: The need for precise speed control and dynamic response in printing applications makes this reactor an ideal fit. Complex Motion Control: Any application with sophisticated multi-axis synchronization and dynamic torque demands will find the 6SL5100-0EE21-6AD0 to be a critical enabling component.

Practical System Integration Guidance

Integrating the SIEMENS 6SL5100-0EE21-6AD0 into a SINAMICS S220 system is designed for efficiency. The reactor serves as a line-side power component that connects between the mains supply and the SINAMICS S220 Smart Line Module. Proper grounding and equipotential bonding are critical for ensuring good electromagnetic compatibility (EMC) and safe operation, as detailed in Siemens' application planning guidelines and EMC installation manuals. For DRIVE-CLiQ connections, it is essential to use only genuine Siemens DRIVE-CLiQ wiring and cabinet bushings to maintain signal integrity and system performance. Referencing the SINAMICS S220 Equipment Manual for detailed wiring diagrams and terminal connections is recommended for successful installation. The standard delivery time is approximately 15 days, and it is crucial to factor this into project planning.

Operation and Risk Mitigation

Safe operation of the SIEMENS 6SL5100-0EE21-6AD0, like all industrial electrical components, requires adherence to established safety protocols. Qualified personnel, possessing the necessary training and experience, should perform installation, commissioning, and maintenance. It is imperative to observe all warning notices and safety instructions provided in the relevant Siemens documentation to prevent injury to persons and damage to property. The line reactors can reach high surface temperatures during operation; therefore, proper mounting and adequate ventilation are crucial to avoid burns. Siemens strongly recommends applying product updates as soon as they become available to mitigate cybersecurity risks and ensure optimal performance. Regular checks for condensation or conductive contamination in the installation environment are also advised.

Scalability & Long-Term Value

The SIEMENS 6SL5100-0EE21-6AD0 is an integral part of the scalable SINAMICS S220 platform, which is an evolution from the well-established SINAMICS S120. This inherent compatibility ensures that the reactor can be integrated into systems that may evolve over time, offering long-term value. The SINAMICS family is designed to support sophisticated drive tasks and can be configured with various harmonized components, allowing for system expansion and adaptation to future requirements. Siemens' commitment to continuous innovation on platforms like SINAMICS S220, coupled with the availability of engineering tools like SIZER, supports efficient system design and potential upgrades, contributing to the overall longevity and return on investment for users. Integration into IIoT and digital solutions is a key aspect of modern Siemens offerings, ensuring that drive systems can contribute to smart factory initiatives.

Frequently Asked Questions (FAQs)

What is the primary function of the SIEMENS 6SL5100-0EE21-6AD0?

The SIEMENS 6SL5100-0EE21-6AD0 functions as a line reactor for the SINAMICS S220 drive system. Its main purpose is to limit harmonic currents on the supply line, thereby improving the power quality delivered to the SINAMICS S220 Smart Line Module. This protection helps prevent premature aging and potential damage to the drive components caused by harmonic distortion.

This reactor also plays a role in electromagnetic compatibility (EMC) by reducing high-frequency noise emitted back onto the power grid. By filtering these disturbances, it contributes to the overall stability and reliability of the automated system. It is an essential component for meeting specific industrial standards for power quality.

The 6SL5100-0EE21-6AD0 is specifically designed for the 16kW SINAMICS S220 Smart Line Module, ensuring optimal impedance matching and performance characteristics. Its integration is crucial for applications requiring precise motor control and efficient power utilization.

What are the key advantages of using the D-Type reactor for SINAMICS S220?

The D-Type designation of the SIEMENS 6SL5100-0EE21-6AD0 signifies its optimization for highly dynamic and intermittent duty cycles. This means it can effectively handle frequent and rapid changes in motor speed and load.

A significant advantage is its ability to tolerate overloads of up to 300% for short durations, which is critical for applications involving high acceleration and deceleration demands. This capability enhances the responsiveness and performance of the drive system.

The D-Type reactor ensures that the SINAMICS S220 drive can achieve its full potential in dynamic applications, contributing to increased machine throughput and productivity without compromising the integrity of the drive components.

How does the booksize form factor benefit system integration?

The booksize form factor of the SIEMENS 6SL5100-0EE21-6AD0 is a key design feature for modern industrial control cabinets. It allows for highly compact and space-efficient installations, which is increasingly important in densely populated automation environments.

This compact design enables machine builders to create smaller overall machine footprints or to fit more functionality within the same cabinet space. This can lead to cost savings in terms of cabinet size and associated electrical infrastructure.

The standardized booksize dimensions also facilitate modularity and ease of assembly. Components with this form factor can be efficiently arranged and interconnected, streamlining the installation and commissioning process for system integrators.

What input voltage and power rating does this reactor support?

The SIEMENS 6SL5100-0EE21-6AD0 is designed to operate with a 3-phase AC input voltage range of 380 to 480 Volts. This voltage range is common in many industrial power grids worldwide, making it a versatile choice for various installations.

The reactor is rated for a 16 kW motor power output. This specification indicates the maximum power of the SINAMICS S220 Smart Line Module that it is designed to protect and complement effectively.

This combination of voltage and power rating makes the 6SL5100-0EE21-6AD0 a specific solution for 16kW SINAMICS S220 applications operating on standard industrial power supplies.

What are the typical applications for the SIEMENS 6SL5100-0EE21-6AD0?

This reactor is ideal for applications requiring high dynamic performance and frequent load changes, such as in machine tools, robotics, and automated assembly lines. Its D-Type designation is key here.

Industries like packaging, material handling, and printing, which often involve high-speed intermittent operations, will benefit from the reactor's overload handling capabilities. This ensures consistent performance under demanding cycles.

Essentially, any scenario demanding precise motor control, rapid acceleration/deceleration, and protection against line harmonics can leverage the SIEMENS 6SL5100-0EE21-6AD0 for enhanced reliability and operational efficiency.

Is this reactor compatible with other Siemens SINAMICS drives?

The SIEMENS 6SL5100-0EE21-6AD0 is specifically designed and optimized for the SINAMICS S220 Smart Line Module. Its primary role is to interface with and protect this particular drive series.

While the SINAMICS S220 platform is an evolution from the SINAMICS S120, and there's commonality in the overall SINAMICS family, direct compatibility of this specific reactor with older or different SINAMICS models is not guaranteed without verification.

For best performance and guaranteed compatibility, it is always recommended to use the SIEMENS 6SL5100-0EE21-6AD0 exclusively with the SINAMICS S220 system as intended by Siemens.

What are the safety considerations when installing this reactor?

Installation of the SIEMENS 6SL5100-0EE21-6AD0 must only be performed by qualified personnel who understand electrical systems and safety procedures. It is crucial to follow all provided documentation, including safety instructions and manuals.

The reactor can become hot during operation, posing a burn risk. Adequate ventilation and clearance around the unit are necessary, and personnel should be aware of this hazard when working in its vicinity.

Proper grounding and equipotential bonding are essential for both safety and electromagnetic compatibility (EMC). Adhering to Siemens' installation guidelines for grounding is critical to prevent electrical shock and ensure system integrity.

What is the typical lead time for the SIEMENS 6SL5100-0EE21-6AD0?

The standard delivery time for the SIEMENS 6SL5100-0EE21-6AD0 is typically around 15 days from the order placement. This lead time is important for project planning and ensuring timely procurement for industrial automation projects.

Availability can fluctuate, and it is advisable to check with distributors or Siemens directly for the most current delivery information, especially for larger quantities or specific project timelines. Expedited shipping options might be available in some cases.

Planning for this lead time helps avoid project delays and ensures that the necessary components are on-site when needed for installation and commissioning of the SINAMICS S220 system.

How does this reactor contribute to system reliability and longevity?

By limiting harmonic currents on the power supply line, the SIEMENS 6SL5100-0EE21-6AD0 significantly reduces stress on the SINAMICS S220 Smart Line Module. This protection helps prevent premature component failure and extends the overall operational lifespan of the drive system.

The reactor also helps mitigate voltage distortions and fluctuations on the mains, leading to more stable and predictable drive performance. This reduced variability contributes to greater system reliability and fewer unexpected shutdowns or errors.

Its robust design, typical of Siemens industrial components, ensures it can withstand demanding operating conditions, further enhancing the overall reliability and long-term value of the automated system it's integrated into.

Are there any specific maintenance requirements for this line reactor?

While line reactors are generally low-maintenance components, regular visual inspections are recommended. Check for any signs of physical damage, loose connections, or unusual noise during operation.

Ensure that the ventilation pathways around the reactor remain clear of dust and debris to prevent overheating and maintain optimal performance. This is particularly important in environments prone to dust accumulation.

Adhering to the general operational guidelines provided by Siemens, such as ensuring proper ambient conditions and avoiding operation outside specified parameters, will contribute to the longevity and reliability of the SIEMENS 6SL5100-0EE21-6AD0 and the entire SINAMICS S220 system.