The OULU EV510A-0900G/1100P-T4 Ultra High Power Heavy Duty Drive VFD 180A 110kW stands as a formidable solution for demanding industrial applications, offering robust performance and advanced control capabilities. This Variable Frequency Drive (VFD) is engineered for superior power management, efficiency, and reliability in heavy-duty operations. Its core advantages lie in its exceptional power density, precise motor control, and comprehensive protection features, making it ideal for sectors requiring high torque and consistent performance under extreme conditions. Key technical parameters include a rated output current of 180A, a maximum power output of 110kW, and compatibility with a 400V-class power system, supporting the "T4" designation indicative of its power and voltage class. The drive's sophisticated design ensures optimal energy savings and extended equipment lifespan, positioning it as a leading choice for critical industrial automation.

Product Specifications

| Parameter | Specification |

| :-------------------- | :------------------------------------------- |

| Model Number | EV510A-0900G/1100P-T4 |

| Rated Output Current | 180A |

| Rated Power Output | 110kW |

| Input Voltage Class | 400V Class |

| Control Method | Vector Control, V/f Control |

| Frequency Range | 0-3000 Hz |

| Overload Capacity | 150% for 60s, 180% for 10s (Heavy Duty) |

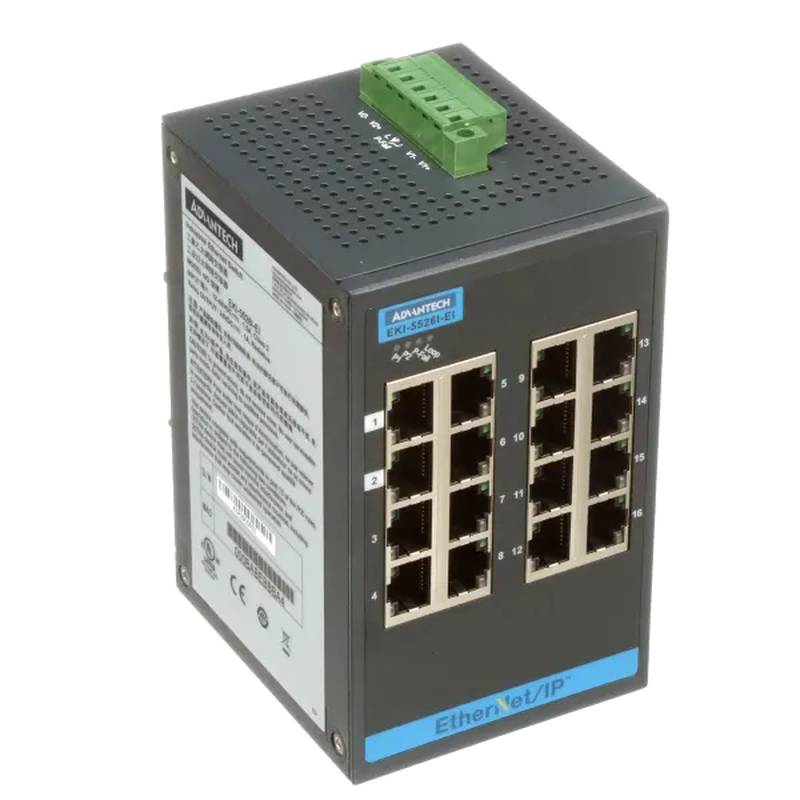

| Communication Options | Modbus RTU, PROFIBUS DP, EtherNet/IP (Optional) |

| Protection Features | Over-voltage, Under-voltage, Over-current, Overload, Overtemperature, etc. |

| Ambient Temperature | -10°C to 40°C (without derating) |

| Dimensions (approx.) | Varies by enclosure; consult datasheet |

Core Features & Market Positioning

The OULU EV510A-0900G/1100P-T4 distinguishes itself through its advanced field-oriented vector control, which provides precise speed and torque regulation even under rapidly changing load conditions. This capability is crucial for applications requiring dynamic response, such as cranes, extruders, and high-power pumps. The drive's robust heavy-duty design ensures it can withstand demanding industrial environments, offering a significant competitive advantage over standard-duty VFDs. Its high overload capacity (150% for 60 seconds) means it can handle transient peak loads without tripping, ensuring uninterrupted operation. OULU's commitment to innovation is evident in its comprehensive communication options, enabling seamless integration into modern industrial control networks and supporting the shift towards Industry 4.0.

Key Application Scenarios

This ultra-high power heavy-duty drive is specifically engineered for applications where extreme performance and reliability are paramount. It excels in controlling large induction motors in industries such as mining, metallurgy, and heavy manufacturing. Common use cases include powering large conveyor systems, industrial fans and blowers, crushers, mixers, and high-capacity pumps for water treatment or oil and gas operations. The drive's ability to provide smooth acceleration and deceleration, coupled with its energy-saving capabilities, makes it an ideal choice for optimizing the operation of energy-intensive machinery, leading to significant operational cost reductions. Its precise torque control also makes it suitable for applications like winding and unwinding machinery where consistent tension is critical.

Practical System Integration Guidance

Integrating the OULU EV510A-0900G/1100P-T4 into existing systems requires careful attention to power wiring and control signal connections. For heavy-duty applications, ensure the power supply is adequately sized and protected with appropriate circuit breakers and fuses as per local electrical codes and the drive's manual. The drive's terminals are clearly marked for line (L1, L2, L3), load (T1, T2, T3), and ground connections. Control wiring, including digital inputs for start/stop and speed selection, analog inputs for speed reference, and relay outputs for fault indication, should be shielded to prevent electromagnetic interference. For advanced integration, optional communication modules allow for network connectivity via protocols like Modbus RTU or EtherNet/IP, requiring proper network cabling and IP address configuration. Referencing the OULU installation manual is crucial for detailed wiring diagrams and specific parameter settings for commissioning.

Operation and Risk Mitigation

Safe and efficient operation of the OULU EV510A-0900G/1100P-T4 hinges on adherence to operating procedures and understanding potential fault conditions. Before powering up, verify all connections, ensure proper grounding, and confirm the input voltage matches the drive's rating to prevent damage. During operation, monitor drive parameters such as output current, voltage, and temperature to detect anomalies early. Common fault codes, such as OC (Over-current), OV (Over-voltage), and OL (Overload), indicate specific issues that need prompt attention, typically requiring a power cycle after the root cause is addressed. Implementing appropriate ventilation and ensuring the ambient temperature stays within the specified limits are critical for preventing thermal overloads and maintaining the drive's long-term reliability.

Scalability & Long-Term Value

The OULU EV510A-0900G/1100P-T4 offers excellent scalability and long-term value by supporting integration with modern industrial automation architectures. Its modular design and available communication interfaces allow for seamless connection to PLC systems and SCADA platforms, enabling centralized monitoring and control. For future upgrades or expansion, the drive's compatibility with a wide range of motor types and its ability to operate in multi-drive configurations provide flexibility. Furthermore, OULU's commitment to developing IIoT-ready solutions means that drives like the EV510A can be incorporated into predictive maintenance programs and smart factory environments, extracting greater value through data analytics and remote diagnostics. This forward-looking approach ensures sustained performance and adaptability to evolving industrial demands.

Frequently Asked Questions

Q1: What is the primary advantage of the OULU EV510A-0900G/1100P-T4 drive?

This drive offers superior torque control for heavy loads.

It provides robust performance in harsh industrial environments.

Its advanced features ensure high energy efficiency and reliability.

Q2: Can this VFD be used with any motor?

It is designed for standard AC induction motors.

Compatibility with specific motor types should be verified.

Consult the product manual for detailed motor parameter settings.

Q3: What is the maximum power output of this drive?

The drive can deliver up to 110kW of power.

This rating is suitable for demanding industrial machinery.

Ensure your motor's power rating does not exceed this limit.

Q4: How does the drive handle sudden load changes?

Its advanced vector control ensures precise torque response.

This minimizes speed fluctuations under dynamic loads.

The high overload capacity also aids in transient situations.

Q5: What are the typical industries that use this drive?

Mining and metallurgy operations frequently use it.

It's also common in heavy manufacturing and processing plants.

Water treatment and oil & gas sectors also benefit from its capabilities.

Q6: Does the drive support network communication?

Yes, it supports popular industrial protocols.

Optional modules enable Modbus, PROFIBUS, and EtherNet/IP.

Network integration allows for remote monitoring and control.

Q7: What are the essential safety considerations during installation?

Proper grounding and adequate power protection are vital.

Always refer to the installation manual for detailed wiring.

Ensure the drive is installed in a well-ventilated area.

Q8: How can I troubleshoot an over-current fault (OC)?

Check for motor short circuits or mechanical jamming.

Verify that the motor's current rating is within the drive's limits.

Reduce the acceleration time or load if necessary.

Q9: What is the environmental operating range for this VFD?

It operates within an ambient temperature of -10°C to 40°C.

Ensure proper ventilation to maintain optimal operating temperatures.

Extreme environmental conditions may require derating or enclosures.

Q10: How does this drive contribute to energy efficiency?

It optimizes motor speed based on load requirements.

This reduces energy consumption compared to fixed-speed operation.

Its advanced control algorithms enhance overall system efficiency.