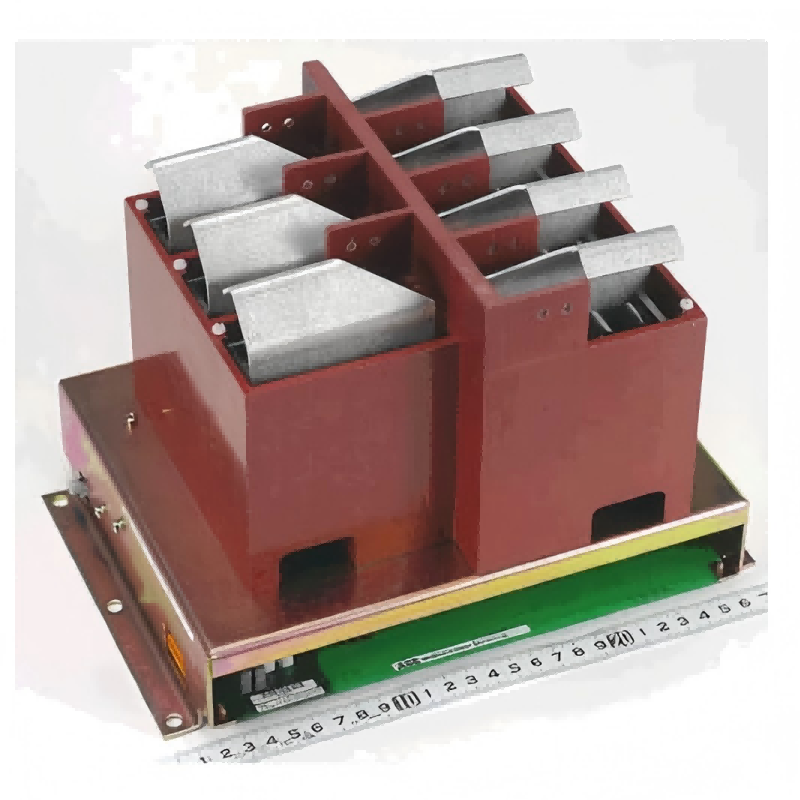

YOULI SN-4/10S Universal Hydraulic Multiple Control Valve: Precision Engineering for Demanding Applications

The YOULI SN-4/10S Universal Hydraulic Multiple Control Valve stands as a testament to advanced hydraulic control technology, engineered for unparalleled precision and reliability in diverse industrial environments. This sectional directional control valve offers robust performance, characterized by its compact construction, low pressure drop, and exceptional efficiency. Designed for longevity, the SN-4/10S features a high-accuracy, hardened spool ensuring sustained operational accuracy over its service life. With a nominal flow rate of 80 L/min (21 US gpm) and a maximum operating pressure of 315 bar (4600 psi) for parallel or tandem circuits, and 250 bar (3050 psi) for series circuits, this valve is a formidable component in high-performance hydraulic systems. The maximum back pressure on the outlet port T is rated at 25 bar (360 psi). Its operational temperature range extends from -20°C to 80°C (with NBR seals) or -20°C to 100°C (with FPM seals), accommodating a wide spectrum of working conditions.

Product Specifications

| Specification | Value |

| :---------------------- | :----------------------------------------- |

| Model | SN-4/10S |

| Nominal Flow Rate | 80 L/min (21 US gpm) |

| Max. Operating Pressure | 315 bar (4600 psi) (Parallel/Tandem) |

| | 250 bar (3050 psi) (Series) |

| Max. Back Pressure (T) | 25 bar (360 psi) |

| Fluid Temperature Range | -20°C to 80°C (NBR seals) |

| | -20°C to 100°C (FPM seals) |

| Ambient Temperature | -40°C to 60°C |

| Viscosity Operating Range | 15-75 mm²/s (cSt) |

| Spool Positions | Various (e.g., 3-position, 4-position) |

| Operation Methods | Manual, Pneumatic, Hydraulic, Electro-hydraulic |

Core Features & Market Positioning

The YOULI SN-4/10S distinguishes itself in the market through its sophisticated design and versatile functionality. Its sectional nature allows for modular configurations, enabling tailored solutions for complex hydraulic circuits. The valve's commitment to quality is underscored by YOULI's long-standing reputation as a professional manufacturer with over three decades of experience in hydraulic control valves since 1975. This dedication is evident in their rigorous quality control processes and meticulous attention to detail at every production stage, ensuring adherence to the finest tolerances. The SN-4/10S is positioned as a high-efficiency, durable component for applications demanding precise fluid power control, offering a competitive edge through its reliability and adaptability.

Key Application Scenarios

The robust design and adaptability of the YOULI SN-4/10S make it suitable for a wide array of demanding industrial applications. Its versatility shines in sectors such as:

Agricultural Machinery: Providing precise control for implements like harvesters, tractors, and sprayers, enhancing operational efficiency and field performance. Construction Equipment: Integral to the operation of excavators, loaders, cranes, and concrete pumps, where accurate and powerful hydraulic actuation is critical. Material Handling and Logistics: Utilized in forklifts, industrial lifts, and automated warehousing systems for reliable load manipulation and movement. Manufacturing and Industrial Automation: Employed in assembly lines, robotic systems, and specialized machinery requiring sophisticated hydraulic control for actuation and positioning. Waste Management Vehicles: Commonly found in garbage trucks and recycling equipment, managing complex hydraulic functions for collection and compaction. Drilling Rigs and Mining Equipment: Its rugged construction and precise control are essential for the demanding conditions in drilling and excavation operations.

Practical System Integration Guidance

Integrating the YOULI SN-4/10S into existing or new hydraulic systems is facilitated by its sub-plate mounting design and comprehensive configuration options. The valve supports various port types, including BSP (e.g., G-3/8, G-1/2, G-3/4) and SAE (e.g., SAE 8, SAE 10). System designers can select from a wide range of spool options, including different configurations for neutral position (e.g., A and B open to tank, A and B closed, single acting with one port plugged) and specific circuit types like series or parallel configurations. The inclusion of optional features such as main pressure relief valves, independent load check valves in each section, and port relief valves further enhances system flexibility and safety. For electro-hydraulic operation, pilot pressure requirements are typically a minimum of 10 bar (145 psi) and a maximum of 50 bar (725 psi), with a solenoid power rating of 21W and a 100% duty cycle.

Operation and Risk Mitigation

Safe and efficient operation of the YOULI SN-4/10S relies on adherence to system design principles and proper maintenance. Key considerations include ensuring the hydraulic fluid is within the specified viscosity and temperature ranges. For instance, the operating viscosity range is 15-75 mm²/s (cSt), with a minimum of 12 cSt and a maximum of 400 cSt. Fluid temperature limits vary based on seal material: -20°C to 80°C for NBR and -20°C to 100°C for FPM. The maximum permissible back pressure on the outlet port T is 25 bar (360 psi), and this should not be exceeded to prevent internal damage or performance degradation. Systems should be designed to operate within the valve's pressure ratings, with appropriate pressure relief settings to safeguard against over-pressurization. Regular inspection of connections, seals, and moving parts will help preemptively address potential issues and ensure the longevity and safety of the hydraulic system.

Scalability & Long-Term Value

The modular, sectional design of the YOULI SN-4/10S inherently supports scalability. Users can configure systems with varying numbers of sections, from one up to twelve. This flexibility allows for system expansion or modification as operational demands change. YOULI Hydraulic’s commitment to quality and durability, backed by decades of manufacturing experience, ensures the SN-4/10S offers significant long-term value. While direct integration with IIoT platforms is not explicitly detailed for this specific valve model, its role as a critical control element in industrial machinery makes it a foundational component for any data acquisition or smart manufacturing initiatives. The precision and reliability of the SN-4/10S contribute to overall system uptime and performance, aligning with the goals of Industry 4.0 initiatives focused on efficiency and predictive maintenance.

*

Frequently Asked Questions (FAQs)

1. What are the primary advantages of the YOULI SN-4/10S valve?

The SN-4/10S offers a compact design, leading to space savings. It boasts a low pressure drop, enhancing system efficiency. Its hardened spool ensures long-term accuracy and durability. The valve supports diverse actuation methods for versatile application.

The modular, sectional construction allows for customized configurations. Users can select from a wide array of spool and port options. This adaptability makes it suitable for numerous complex hydraulic systems.

Its high efficiency and long service life contribute to reduced operational costs. The robust build quality, stemming from YOULI's extensive experience, ensures reliable performance in demanding environments.

2. What is the maximum flow rate and pressure handling capability of the SN-4/10S?

The YOULI SN-4/10S is rated for a nominal flow rate of 80 liters per minute. This equates to approximately 21 US gallons per minute.

Regarding pressure, it can handle up to 315 bar (4600 psi) for parallel or tandem circuits. For series circuits, the maximum operating pressure is 250 bar (3050 psi).

Additionally, the maximum back pressure on the outlet port T is limited to 25 bar (360 psi). Exceeding these limits can compromise performance and component integrity.

3. Can the YOULI SN-4/10S valve be configured for different types of hydraulic circuits?

Yes, the SN-4/10S is designed for flexible circuit integration. It supports parallel, tandem, and series circuit configurations.

Users can specify spool options to achieve desired neutral positions, such as A and B open to tank or closed. This allows for precise control over actuator behavior.

Optional features like port relief valves and independent load check valves further enhance its applicability in various circuit designs, ensuring safety and efficiency.

4. What are the operating temperature and viscosity ranges for the SN-4/10S?

The valve can operate within a fluid temperature range of -20°C to 80°C when equipped with NBR seals. For applications requiring higher temperature resistance, FPM seals extend this range to -20°C to 100°C.

The recommended operating viscosity range for the hydraulic fluid is between 15 and 75 mm²/s (cSt). It can handle a minimum viscosity of 12 cSt and a maximum of 400 cSt.

Maintaining fluid within these parameters is crucial for optimal performance and longevity of the valve and the hydraulic system.

5. What are the available options for spool actuation and configuration on the SN-4/10S?

The SN-4/10S offers a variety of spool options for tailored functionality. This includes configurations for double-acting cylinders with different neutral positions.

It also supports single-acting functions with specific port configurations. Furthermore, options for floating circuits in a fourth position are available for specialized applications.

Actuation methods can be manual, pneumatic, hydraulic, or electro-hydraulic, providing comprehensive control flexibility across different operational needs.

6. How is the SN-4/10S valve typically mounted and integrated into a hydraulic system?

This valve is designed for sub-plate mounting, simplifying installation and maintenance. This mounting style ensures a secure and leak-free connection to the hydraulic manifold.

The inlet and outlet ports are available in standard thread types like BSP (G series) and SAE, facilitating easy interconnection with hydraulic lines. The exact port sizes depend on the specific model configuration.

Multiple working sections can be assembled to create a custom valve assembly tailored to the specific requirements of the hydraulic system.

7. What are the benefits of the sectional design of the SN-4/10S valve?

The sectional design allows for a modular approach to building hydraulic control assemblies. This means you can combine multiple valve sections to create a single unit tailored to your specific needs.

This modularity provides excellent scalability, as you can add or remove sections to adapt to changing system requirements. Configurations can range from a single section up to twelve sections.

It simplifies system design by allowing for a consolidated control unit rather than multiple individual valves, reducing potential leak points and assembly complexity.

8. Does the YOULI SN-4/10S valve come with integrated pressure relief?

Yes, the SN-4/10S can be configured with an integrated main pressure relief valve in the inlet cover. This provides crucial over-pressure protection for the entire valve assembly.

Additionally, optional port relief valves can be specified for individual working sections. These offer localized over-pressure protection for specific actuator lines.

The presence and type of relief valves should be confirmed based on the specific model number and application requirements.

9. What kind of maintenance is recommended for the YOULI SN-4/10S?

Regular visual inspection of the valve and its connections for any signs of leakage is fundamental. Checking the hydraulic fluid level and condition is also essential, ensuring it meets viscosity and cleanliness standards.

Pay attention to the actuation mechanism, whether manual lever or solenoid, for smooth operation. Ensure electrical connections are secure if operating electro-hydraulically.

While designed for longevity, consult the manufacturer's documentation for detailed service intervals. Prompt attention to any anomalies will help maintain optimal performance and prevent potential failures.

10. Where is the YOULI SN-4/10S valve typically used in industrial applications?

The SN-4/10S finds extensive use in mobile hydraulic equipment. This includes agricultural machinery, construction vehicles, and material handling equipment like forklifts.

It is also prevalent in various industrial automation systems. Applications range from manufacturing assembly lines to specialized industrial machinery requiring precise hydraulic control.

Its adaptability makes it suitable for specialized equipment such as garbage trucks and drilling rigs, where robust and reliable hydraulic actuation is paramount.