The INVT GD350A-800G-4 is an advanced Variable Frequency Drive (VFD) engineered for demanding industrial applications, delivering superior motor control and energy efficiency. This robust drive boasts a nominal power rating of 75kW (100HP) and operates on a 400V class power supply, making it suitable for a wide range of heavy-duty machinery. Its key advantages lie in its sophisticated vector control algorithms, comprehensive protection features, and flexible communication options, positioning it as a high-performance solution for optimizing industrial processes.

| Specification | Value |

| :---------------------------- | :----------------------------------------- |

| Model | GD350A-800G-4 |

| Rated Power Output | 75kW (100HP) |

| Input Voltage Class | 400V |

| Control Method | Sensorless Vector Control, V/f Control |

| Overload Capacity | 150% for 60s, 180% for 3s |

| Output Frequency Range | 0-400Hz |

| Braking Unit | Integrated (optional external resistor) |

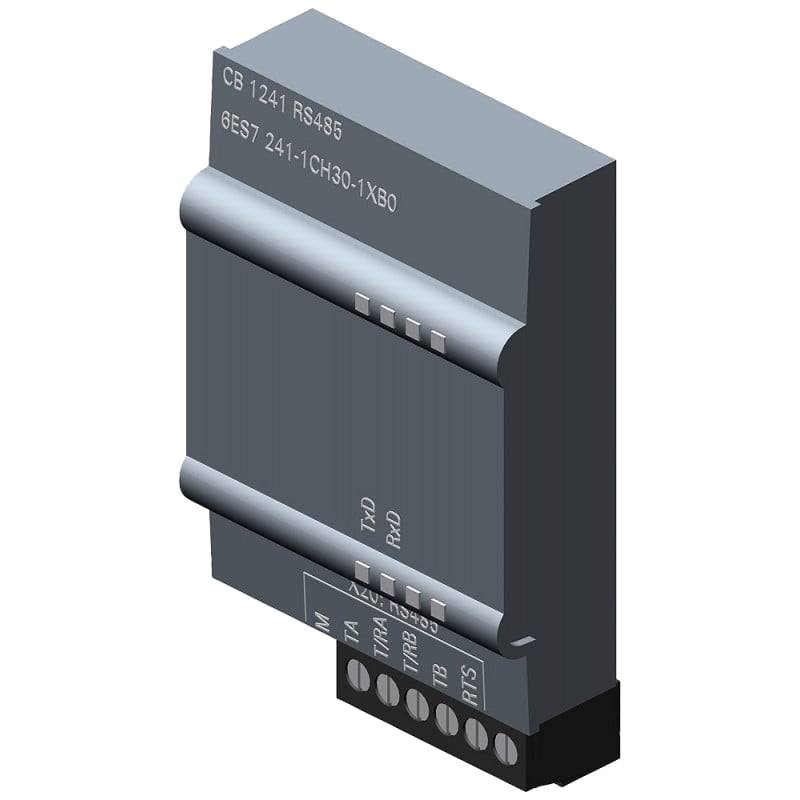

| Communication Interfaces | RS485 (Modbus), optional fieldbus modules |

| Protection Features | Over-voltage, Under-voltage, Overload, etc. |

| Ambient Temperature Operating | -10°C to 40°C |

| Altitude | Up to 1000m without derating |

Core Features & Market Positioning

The INVT GD350A-800G-4 distinguishes itself through its advanced sensorless vector control, providing exceptional torque response and precision even under fluctuating load conditions. This technology is critical for applications requiring dynamic speed and torque regulation, such as cranes, extruders, and material handling systems. Its robust design, incorporating a powerful heatsink and advanced thermal management, ensures reliable operation in harsh industrial environments. The integrated braking unit offers robust deceleration capabilities, enhancing safety and process control. Furthermore, the GD350A-800G-4 supports a wide array of communication protocols, including Modbus RTU via its standard RS485 interface, with options for integrating various fieldbus modules, facilitating seamless integration into sophisticated automation networks and contributing to its strong market positioning for high-performance industrial automation.

Key Application Scenarios

This advanced VFD finds its optimal application in sectors demanding high precision and reliability. In manufacturing, it excels in controlling conveyors, mixers, and centrifugal pumps where precise speed and torque are paramount. The GD350A-800G-4 is particularly well-suited for the textile industry, powering looms and spinning machines with its accurate motor control. In the plastics industry, it is invaluable for extruders and injection molding machines, ensuring consistent product quality. Furthermore, its robust performance makes it an excellent choice for HVAC systems, managing fan and pump speeds efficiently to optimize energy consumption in large commercial and industrial buildings.

Practical System Integration Guidance

Integrating the INVT GD350A-800G-4 into an existing system is streamlined due to its user-friendly interface and comprehensive documentation. Proper wiring is crucial for optimal performance and safety. Ensure the main power terminals (L1, L2, L3) are connected to the appropriate AC supply, and the motor terminals (U, V, W) are securely connected to the motor. For digital inputs/outputs (DI, DO) and analog inputs (AI), follow the terminal diagrams precisely to configure functions like start/stop, speed commands, and feedback signals. Parameter programming is typically performed via the drive's keypad or through serial communication using INVT's dedicated software. Initial setup should involve configuring motor parameters (e.g., rated voltage, current, frequency) and control mode (sensorless vector control is recommended for most applications).

Operation and Risk Mitigation

Operating the INVT GD350A-800G-4 requires adherence to safety protocols. Always ensure power is completely disconnected before performing any wiring or maintenance. The drive features numerous protection mechanisms to prevent damage to itself and the connected motor. Common fault codes, such as "Overcurrent" (OC), "Overvoltage" (OV), and "Overload" (OL), indicate abnormal operating conditions that require immediate attention. For instance, an OC fault might suggest an acceleration ramp that is too steep or a motor with insufficient torque capability for the load. Addressing these requires reviewing drive parameters, load characteristics, and motor specifications to identify the root cause and implement corrective actions, such as adjusting acceleration times or selecting a more appropriately sized motor.

Scalability & Long-Term Value

The INVT GD350A-800G-4 offers significant long-term value through its inherent scalability and compatibility with modern industrial automation trends. Its modular design allows for the addition of optional communication cards, enabling integration with diverse industrial networks like PROFIBUS, PROFINET, or EtherNet/IP, essential for smart factory initiatives. This flexibility ensures the drive can adapt to evolving automation architectures and remain a viable component in upgraded systems. Furthermore, the drive's robust construction and INVT's commitment to firmware updates contribute to its longevity, minimizing the need for premature replacement and supporting sustainable industrial operations. Its compatibility with cloud-based monitoring solutions also opens avenues for predictive maintenance and enhanced operational efficiency within an IIoT framework.

---

Frequently Asked Questions

Q1: What are the primary benefits of using the INVT GD350A-800G-4?

The GD350A-800G-4 offers precise motor control via advanced sensorless vector technology. It significantly enhances energy efficiency by optimizing motor speed and torque output. This drive also features robust overload capacity and comprehensive protection, ensuring operational reliability and longevity for critical industrial machinery.

Q2: Can the INVT GD350A-800G-4 be used with any type of motor?

Primarily, this VFD is designed for three-phase induction motors, which are standard in industrial settings. It supports a wide frequency range and torque control, making it versatile. Always verify motor compatibility, including voltage, current, and power ratings, against the drive's specifications for optimal performance.

Q3: How do I perform initial parameter setup for the GD350A-800G-4?

Begin by inputting the motor's nameplate data: voltage, frequency, rated current, and pole numbers. Then, select the control mode, typically sensorless vector control for best performance. It is crucial to adjust acceleration and deceleration times to match the mechanical system's inertia and response capabilities.

Q4: What are common causes for an "Overcurrent" (OC) fault on this VFD?

An OC fault can stem from excessively fast acceleration settings, a load exceeding the motor's torque capability, or motor winding issues. It may also indicate a short circuit in the motor or cabling. Checking the motor's current rating against the drive's output and reviewing load dynamics is essential for diagnosis.

Q5: Does the GD350A-800G-4 support communication with PLCs?

Yes, the drive includes a standard RS485 port for Modbus RTU communication, allowing seamless integration with most PLCs. Optional communication cards are available to support other industrial protocols like PROFIBUS, PROFINET, and EtherNet/IP for advanced networking needs.

Q6: What is the overload capacity of the INVT GD350A-800G-4?

The drive can handle 150% of its rated current for 60 seconds, and an impressive 180% for 3 seconds. This robust overload capability ensures stable operation during transient load peaks and start-up sequences in demanding applications, preventing nuisance tripping.

Q7: How does the integrated braking unit function?

The integrated braking unit allows for controlled deceleration of the motor by dissipating excess regenerative energy as heat, usually through an external braking resistor. This feature is vital for applications where quick stopping is required, preventing dangerous overvoltage conditions.

Q8: What is the typical operating temperature range for this VFD?

The INVT GD350A-800G-4 is designed to operate reliably within an ambient temperature range of -10°C to 40°C (14°F to 104°F). Operating outside this range, especially at higher temperatures, may require derating or enhanced cooling solutions.

Q9: Can this VFD be used for high-speed applications?

Yes, the GD350A-800G-4 supports an output frequency range of up to 400Hz, making it suitable for applications requiring motor speeds above their base frequency. Ensure the motor is rated for such speeds and that proper cooling is maintained.

Q10: How can the GD350A-800G-4 contribute to energy savings?

By precisely controlling motor speed based on actual demand, rather than running at full speed, the VFD significantly reduces energy consumption. This is particularly effective in applications with variable loads, such as pumps and fans, leading to substantial operational cost savings over time.