The Delta DVP20EX200T EX Series Compact Programmable Controller Main Unit stands as a robust and versatile solution for a wide array of industrial automation tasks. Engineered for efficiency and reliability, this PLC offers exceptional processing power within a compact form factor, making it ideal for applications where space is at a premium. Its core advantages lie in its high-speed performance, extensive I/O capabilities, and seamless integration potential with other industrial systems. Key technical parameters include a generous memory capacity, a wide operating temperature range, and support for various communication protocols, ensuring adaptability across diverse operational environments.

Product Specifications

| Feature | Specification |

| :----------------------- | :--------------------------------------------------- |

| Product Series | DVP-EX2 Series |

| Model Number | DVP20EX200T |

| Type | Compact Programmable Controller Main Unit |

| Digital Inputs | 12 |

| Digital Outputs | 8 (Transistor Output) |

| Power Supply | 100-240VAC |

| Max. Program Steps | 16k Steps |

| Communication Ports | RS-232, RS-485 |

| Built-in Functions | High-speed counting, Pulse train output |

| Operating Temperature | 0°C to 50°C (32°F to 122°F) |

| Storage Temperature | -40°C to 60°C (-40°F to 140°F) |

| Ambient Humidity | 5% to 95% (non-condensing) |

| Dimensions (W x H x D) | 140mm x 90mm x 60mm |

Core Features & Market Positioning

The Delta DVP20EX200T distinguishes itself in the competitive PLC market through its superior processing speed and flexible I/O configuration. Its transistor output type is particularly well-suited for high-speed switching applications, such as those found in packaging machinery and advanced assembly lines. This unit excels in providing precise control over complex motion sequences, a critical factor for manufacturers seeking to optimize throughput and product quality. Delta's EX Series is positioned as a high-performance, cost-effective solution for small to medium-sized automation projects, offering capabilities that rival larger, more expensive controllers. The built-in high-speed counting and pulse train output functions eliminate the need for additional specialized modules, further reducing system cost and complexity.

Key Application Scenarios

The versatility of the Delta DVP20EX200T makes it a prime choice for a broad spectrum of industrial applications. It is frequently deployed in standalone machine control, where its compact size and integrated functionality streamline panel design and reduce wiring. Common use cases include precise control for conveyor systems, automated material handling, textile machinery, and sophisticated process control loops requiring rapid response times. For industries such as food and beverage, pharmaceuticals, and printing, the unit's reliability and ability to manage intricate sequences are invaluable for ensuring consistent production and compliance with stringent quality standards. Its adaptability also makes it suitable for building automation and HVAC control systems demanding efficient and reliable operation.

Practical System Integration Guidance

Integrating the Delta DVP20EX200T into an existing or new system is straightforward, leveraging Delta's user-friendly ISPSoft programming software. For typical wiring, ensure proper grounding and adherence to voltage specifications for the power supply and I/O points. The RS-232 and RS-485 ports allow for straightforward communication with HMIs, SCADA systems, and other intelligent devices, often using Modbus RTU protocol. When implementing high-speed I/O, careful consideration of signal integrity and shielding is recommended to prevent noise interference. For pulse train output applications, ensure the connected drives or servo controllers are compatible with the DVP20EX200T's output frequency and signal format.

Operation and Risk Mitigation

Safe operation of the Delta DVP20EX200T requires adherence to electrical safety standards and proper handling procedures. Always disconnect power before performing any wiring or maintenance. Ensure the ambient operating environment remains within the specified temperature and humidity ranges to prevent component degradation. Potential troubleshooting scenarios often involve checking power supply stability, verifying wiring integrity, and reviewing program logic for common errors such as incorrect addressing or data type mismatches. While specific fault codes are detailed in the user manual, common issues might relate to input signal faults, output overloads, or communication errors, all of which can be diagnosed through status indicators and diagnostic tools within ISPSoft.

Scalability & Long-Term Value

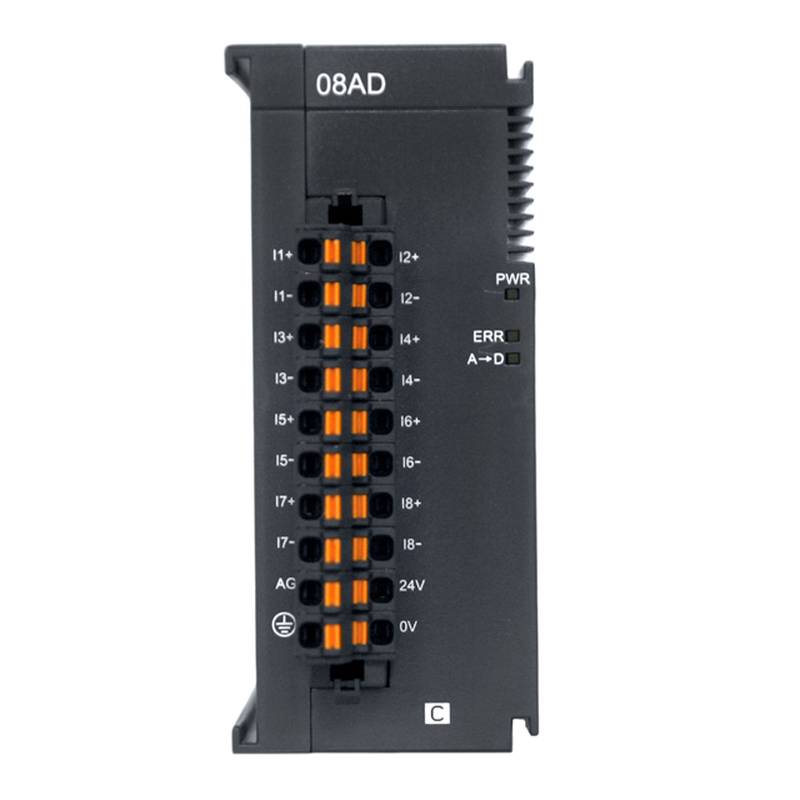

The Delta DVP20EX200T offers significant scalability, allowing systems to grow alongside production demands. While it is a compact unit, it can be networked with other Delta PLCs or expansion modules to increase I/O count or communication capabilities. Its compatibility with Delta's broader automation ecosystem, including HMI panels and servo drives, provides a cohesive platform for advanced automation solutions. For businesses embracing Industry 4.0 initiatives, the DVP20EX200T can be integrated into IIoT platforms through appropriate communication gateways, enabling remote monitoring, data logging, and predictive maintenance strategies. This forward-thinking design ensures long-term value by supporting evolving technological requirements and enhancing overall operational intelligence.

FAQs

1. What are the primary advantages of the Delta DVP20EX200T EX Series PLC?

This PLC offers high-speed processing capabilities essential for demanding control tasks. Its compact design is perfect for space-constrained automation panels. The unit provides a versatile mix of digital inputs and transistor outputs for flexible I/O configuration.

2. What types of industrial applications are best suited for the DVP20EX200T?

It excels in standalone machine control applications needing precise motion. Common uses include packaging, printing, and material handling equipment. The PLC is also ideal for process control requiring rapid response times.

3. How does the DVP20EX200T facilitate system integration?

The PLC supports standard communication protocols like RS-232 and RS-485 for easy HMI/SCADA connectivity. It integrates smoothly with Delta's own automation product lines. Programming is simplified using the intuitive ISPSoft software environment.

4. What are the key technical specifications regarding I/O for this PLC?

The DVP20EX200T features 12 digital inputs for sensor interfacing. It is equipped with 8 digital outputs of the transistor type, ideal for high-speed switching. This configuration supports advanced functions like pulse train output.

5. What programming software is used with the Delta DVP20EX200T?

The primary software for programming this PLC is Delta's ISPSoft. This integrated development environment allows for ladder logic and function block programming. It also facilitates debugging and system diagnostics.

6. Can the DVP20EX200T handle high-speed counting and motion control tasks?

Yes, the unit has built-in support for high-speed counting functions. It also includes capabilities for pulse train output, enabling basic motion control applications. These features reduce the need for external modules.

7. What are the power requirements and operating environment considerations for this PLC?

The main unit operates on a wide AC input voltage range of 100-240VAC. It is designed for industrial environments with an operating temperature range of 0°C to 50°C. Proper ventilation is crucial to maintain optimal performance.

8. How can the DVP20EX200T be scaled for larger automation systems?

It can be networked with other Delta PLCs or expansion modules. This allows for increased digital and analog I/O points as needed. Communication options facilitate integration into larger distributed control systems.

9. What communication protocols does the DVP20EX200T support?

The PLC is equipped with built-in RS-232 and RS-485 serial communication ports. These typically support industry-standard protocols such as Modbus RTU. This enables seamless data exchange with various devices.

10. What are common troubleshooting steps for the Delta DVP20EX200T?

First, verify the AC power supply is stable and within specifications. Next, meticulously check all input/output wiring connections for correctness and security. Finally, review the program logic for errors in addressing or execution flow.