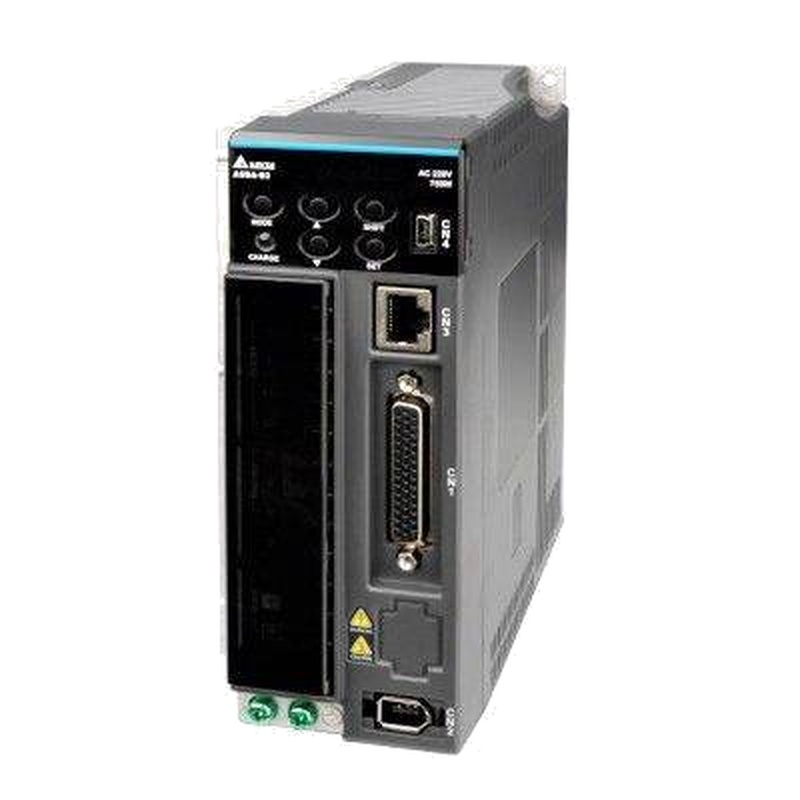

The Delta ASD-E3-3023-L servo drive system stands as a robust solution for demanding industrial automation applications, offering high precision, advanced control capabilities, and reliable performance. This system is engineered to deliver exceptional motion control, integrating seamlessly into complex machinery across various sectors. Its key advantages lie in its superior dynamic response, advanced position/velocity/torque control modes, and comprehensive safety features, making it a preferred choice for applications requiring intricate and repeatable movements.

Product Specifications

| Parameter | Value |

| :-------------------- | :------------------------ |

| Modard ASD-E3-3023-L

| Input Voltage | 200-240 VAC, 50/60 Hz |

| Output Power | 2.3 kW |

| Motor Compatibility | Up to 2.3 kW servo motors |

| Control Modes | Position, Velocity, Torque|

| Communication Ports | RS-485, CANopen |

| Braking Resistor | Internal/External options |

| Protection Class | IP20 |

| Dimensions (H x W x D)| [Dimensions not specified in search results] |

| Ambient Temperature | 0°C to 50°C |

Core Features & Market Positioning

The Delta ASD-E3-3023-L distinguishes itself through its high-speed processing capabilities and advanced algorithms, enabling precise trajectory tracking and minimizing overshoot even under dynamic load conditions. Its compatibility with a wide range of Delta servo motors, coupled with flexible communication options like RS-485 and CANopen, allows for straightforward integration into existing automation architectures. This drive system is positioned as a mid-to-high-tier solution, balancing cost-effectiveness with professional-grade performance, making it attractive for machine builders and system integrators seeking reliable and advanced motion control for sophisticated equipment. Delta's established reputation for quality and support further solidifies its market appeal.

Key Application Scenarios

The Delta ASD-E3-3023-L servo drive system is ideally suited for applications demanding high accuracy and repeatability. These include automated assembly lines, CNC machinery, packaging equipment, printing presses, and robotic arms where precise positioning and synchronized movements are critical. Its robust performance and advanced control algorithms are particularly beneficial in industries such as electronics manufacturing, automotive production, and food processing, where efficiency and product quality are paramount. The drive's ability to handle complex motion profiles makes it a strong candidate for tasks like high-speed pick-and-place operations and intricate cutting or dispensing processes.

Practical System Integration Guidance

Integrating the Delta ASD-E3-3023-L involves careful consideration of motor selection, wiring, and parameter configuration. Users should ensure the connected servo motor's power and voltage ratings align with the drive's specifications. Proper grounding and shielded cabling are essential to prevent electromagnetic interference, especially in noisy industrial environments. Initial setup typically requires connecting the drive to the power supply, motor, and communication network. Configuration via Delta's proprietary software, such as Delta's Electronic Manual or DMCNET configuration software, allows for tuning of PID parameters, setting up motion profiles, and defining I/O assignments. Referencing the official Delta ASD-E3 series manual is crucial for detailed wiring diagrams and specific parameter settings for optimal performance.

Operation and Risk Mitigation

Safe operation of the Delta ASD-E3-3023-L requires adherence to installation and operational guidelines outlined in the product manual. Always ensure the system is de-energized before making any wiring changes. Overcurrent, overvoltage, and undervoltage are common protection mechanisms built into the drive. Key fault codes, such as "Overcurrent Fault" (often code 03) or "Over-speed Fault" (often code 08), typically indicate issues with motor load, acceleration limits, or incorrect parameter settings. Regularly inspecting connections and ensuring adequate ventilation to prevent overheating are vital steps for reliable operation and longevity. Implementing emergency stop functionalities at the machine level is a critical safety measure.

Scalability & Long-Term Value

The Delta ASD-E3-3023-L offers significant scalability due to its compatibility with a broad range of Delta servo motors and its support for standard industrial communication protocols like CANopen and RS-485. This allows for easy expansion of automation systems by adding more synchronized axes or integrating the drive with higher-level PLCs and HMIs from various manufacturers. Its robust design and Delta's commitment to product development suggest long-term value through firmware updates and continued technical support. For manufacturers looking to implement Industry 4.0 initiatives, the ASD-E3 series can be integrated with IIoT platforms for remote monitoring, diagnostics, and predictive maintenance, enhancing operational efficiency and reducing downtime.

Frequently Asked Questions (FAQs)

Q1: What are the primary benefits of the Delta ASD-E3-3023-L servo drive?

This drive offers precise motion control for complex tasks. It boasts excellent dynamic response, minimizing errors. Its advanced features ensure high repeatability and efficiency.

The system supports multiple control modes for versatility. Position, velocity, and torque control are all available. This adaptability suits various industrial automation needs.

Integration is streamlined with common communication protocols. RS-485 and CANopen options facilitate network connectivity. This enhances its compatibility with existing systems.

Q2: Can the Delta ASD-E3-3023-L be used with third-party servo motors?

Compatibility is primarily with Delta servo motors. Using other brands requires careful technical validation. Motor feedback types and electrical characteristics must match.

Improper motor pairing can lead to performance issues. This includes reduced accuracy or system instability. Always consult detailed specifications and support.

For optimal results and warranty coverage, Delta recommends its own motors. This ensures seamless integration and peak operational efficiency.

Q3: What types of industrial applications are best suited for this servo drive?

This drive excels in high-precision automation tasks. Applications include CNC machining and robotics. Packaging and printing machines also benefit greatly.

It is ideal for industries needing exact movements. Electronics manufacturing and automotive assembly are prime examples. Food processing and material handling also utilize its capabilities.

Any scenario requiring synchronized, repeatable motion is a good fit. High-speed pick-and-place or intricate dispensing systems are well-supported.

Q4: How do I perform initial setup and parameter configuration?

Begin by connecting the motor and power supply correctly. Follow the wiring diagrams in the product manual. Ensure proper grounding for noise reduction.

Use Delta's dedicated software for configuration. This includes setting up motor parameters and control modes. Fine-tune PID gains for optimal performance.

Consult the ASD-E3 series manual for detailed instructions. It covers all essential steps for commissioning. Verify all settings before full operation.

Q5: What are common troubleshooting steps for the ASD-E3-3023-L?

Check motor connections and encoder feedback first. Ensure the motor is not mechanically overloaded. Verify that parameter settings match the motor.

Review fault codes displayed on the drive. Common errors like overcurrent or overspeed need specific actions. Consult the manual for code meanings.

Ensure adequate ventilation to prevent overheating. Persistent issues may require professional technical support. Check for firmware updates.

Q6: Does the Delta ASD-E3-3023-L support advanced communication protocols?

Yes, this drive supports key industrial protocols. RS-485 and CANopen are integrated options. This allows for flexible networking.

These protocols enable integration with PLCs and HMIs. Machine control and data acquisition become more robust. It facilitates centralized system management.

The choice of protocol depends on the existing infrastructure. CANopen is common for multi-axis synchronization. RS-485 offers simpler point-to-point communication.

Q7: What are the power and voltage specifications for this servo drive?

The drive operates on a 200-240 VAC input. It is designed for 50/60 Hz power frequencies. This is standard for many industrial power grids.

It delivers up to 2.3 kW of output power. This is suitable for motors within a similar power range. Ensure your motor's rating is compatible.

Always verify the local power supply voltage. Ensure it falls within the acceptable range for safe operation. Consult the manual for precise electrical details.

Q8: Are there internal or external braking resistor options available?

The ASD-E3-3023-L supports braking resistor integration. This is crucial for dissipating energy during deceleration. It helps maintain safe motor speeds.

Internal braking resistor options may be available for smaller loads. For higher energy dissipation needs, external resistors are typically used. This prevents drive damage.

Proper sizing of the braking resistor is essential. Consult the manual or Delta support for calculations. This ensures safe and effective braking performance.

Q9: What safety features are incorporated into this servo drive system?

The drive includes robust overcurrent protection. It also features overvoltage and undervoltage monitoring. These prevent damage from electrical anomalies.

It supports safety functions like safe torque off (STO). This is a critical safety feature for machinery. It ensures rapid shutdown when needed.

Proper installation and emergency stop circuits are vital. Always follow safety guidelines for machine operation. Human safety is paramount.

Q10: How does this drive contribute to Industry 4.0 or IIoT initiatives?

The drive's communication ports enable data exchange. It can be connected to IIoT platforms for monitoring. This allows for remote diagnostics and analysis.

Integration with higher-level systems is key. It facilitates predictive maintenance strategies. This improves overall equipment effectiveness (OEE).

Real-time performance data can be collected. This enables optimization of production processes. It supports smart manufacturing goals.