The Siemens 6SL3730-730-8BA3 SINAMICS S120 Cabinet ALM with AIM 235kW 380A Industrial Energy Recovery Unit (400V) represents a pinnacle of advanced motor control and energy management for demanding industrial applications. This integrated solution offers significant advantages, including substantial energy savings through regenerative braking, precise motion control, and enhanced system reliability. Its core features include a robust cabinet design, high power density, and seamless integration with Siemens' broader automation ecosystem. Key technical parameters highlight its 235kW power rating, 380A nominal current, and 400V operating voltage, making it suitable for heavy-duty machinery.

| Feature | Specification |

| :----------------------------- | :---------------------------------------------- |

| Product Number | 6SL3730-730-8BA3 |

| Product Family | SINAMICS S120 Cabinet ALM |

| Power Rating | 235 kW |

| Nominal Current | 380 A |

| Operating Voltage | 400 V |

| Functionality | Industrial Energy Recovery Unit (AIM) |

| Enclosure Type | Cabinet |

Core Features & Market Positioning

The SINAMICS S120 Cabinet ALM distinguishes itself through its sophisticated Energy Recovery Unit (AIM) functionality, a key differentiator in the industrial automation market. This feature enables the drive to actively feed generated energy back into the supply network during braking or deceleration phases, leading to significant operational cost reductions and improved environmental footprint. Its market positioning is that of a premium, high-performance solution for applications requiring precise, dynamic motor control coupled with efficient energy management. Siemens' reputation for robust engineering and reliable components further solidifies its standing as a trusted choice for mission-critical industrial processes. The integrated design minimizes external cabling and component requirements, simplifying installation and reducing potential points of failure.

Key Application Scenarios

This Siemens SINAMICS S120 unit is ideally suited for a wide array of demanding industrial applications where energy efficiency and precise motion control are paramount. Common scenarios include:

Material Handling Systems: Cranes, hoists, and conveyor belts in ports, warehouses, and heavy manufacturing benefit from the regenerative braking capabilities to reduce energy consumption during load lowering and stopping. Machine Tools: High-precision lathes, milling machines, and presses utilize the dynamic response and accurate control of the SINAMICS S120 for complex machining operations, with energy recovery contributing to lower operating costs. Extrusion and Winding Machines: Industries such as plastics, paper, and textiles leverage the smooth acceleration and deceleration profiles for consistent product quality and reduced mechanical stress, enhanced by energy regeneration. Test Benches and Dynamometers: Applications requiring precise speed and torque control, along with the ability to capture and utilize generated energy, find this unit highly effective.

Practical System Integration Guidance

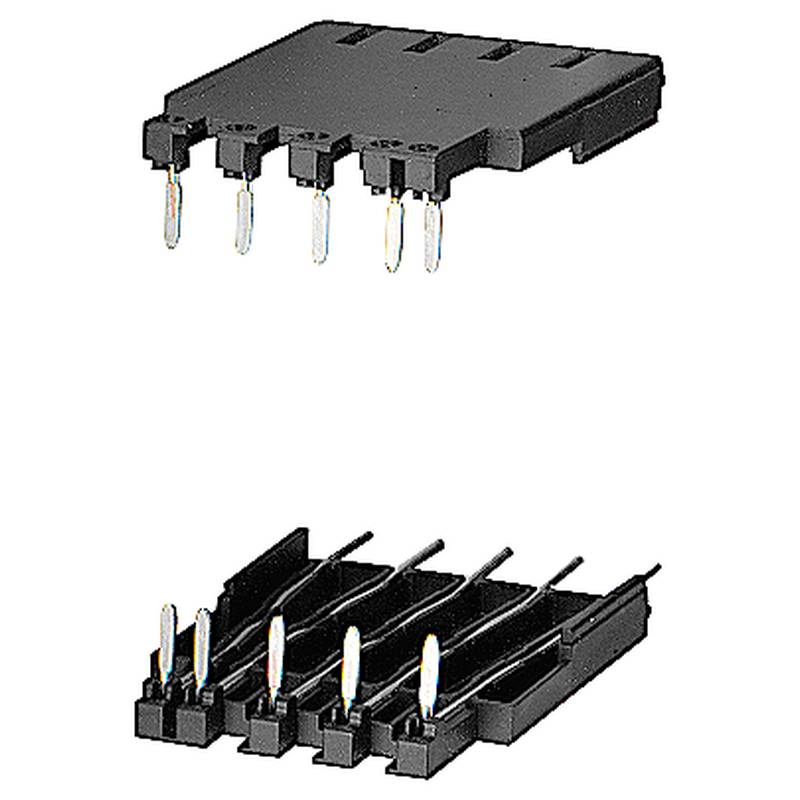

Integrating the Siemens 6SL3730-730-8BA3 SINAMICS S120 Cabinet ALM requires adherence to specific electrical and communication protocols. Proper grounding and shielded cabling are essential to mitigate electromagnetic interference (EMI) and ensure reliable operation. The unit typically connects to a higher-level control system via industrial Ethernet protocols such as PROFINET or PROFIBUS, allowing for sophisticated diagnostics and parameterization. Commissioning involves configuring motor data, application-specific parameters, and safety functions using Siemens' TIA Portal software. The AIM module requires specific wiring for energy feedback, typically connecting directly to the main power infeed point or a designated busbar.

Operation and Risk Mitigation

Safe and efficient operation of the SINAMICS S120 Cabinet ALM hinges on understanding its operational parameters and potential fault conditions. Users must ensure the drive is operated within its specified voltage (400V) and current (380A) limits to prevent overheating or component damage. During operation, monitoring drive status via the Human-Machine Interface (HMI) or TIA Portal is crucial for detecting anomalies. Common troubleshooting involves checking power supply quality, motor connections, and encoder feedback. Critical error codes, such as those related to overcurrent, overvoltage, or communication failures, should be cross-referenced with the official Siemens SINAMICS S120 documentation for detailed diagnostic and resolution procedures. Implementing appropriate safety interlocks and emergency stop functionalities is paramount for personnel safety.

Scalability & Long-Term Value

The SINAMICS S120 platform offers significant scalability and long-term value, especially when integrated within the Siemens Digital Industries portfolio. The modular design of the S120 system allows for expansion and adaptation to evolving production needs. This specific cabinet unit can be networked with other SINAMICS drives or SIMOTICS motors, facilitating complex machine configurations. Its compatibility with TIA Portal ensures that it can be easily integrated into modern automation architectures, including those leveraging IIoT (Industrial Internet of Things) for predictive maintenance, remote monitoring, and advanced analytics. This forward-thinking integration capability ensures that the Siemens 6SL3730-730-8BA3 remains a relevant and valuable asset throughout its operational lifespan.

Frequently Asked Questions (FAQs)

What is the primary function of the AIM in the Siemens 6SL3730-730-8BA3?

The AIM (Active Infeed Module) enables regenerative braking. It feeds energy back to the grid during deceleration. This significantly reduces overall energy consumption.

The AIM module actively manages power flow for efficient energy recovery. It is crucial for optimizing operational costs. This feature also enhances the environmental sustainability of industrial processes.

It contributes to a stable power grid by compensating for reactive power. This improves the power factor of the installation. It also ensures a cleaner energy supply.

How does the Siemens 6SL3730-730-8BA3 achieve energy recovery?

It utilizes advanced power electronics to invert DC to AC. This allows generated energy to be returned to the supply network. The process is controlled by sophisticated algorithms within the drive.

This energy recovery capability lowers electricity bills. It also reduces the thermal load on braking resistors. This extends the lifespan of other drive components.

The collected energy can be reused by other equipment on the same network. This creates a more efficient and self-sustaining system. It minimizes wasted energy.

What are the typical industries that benefit from this unit?

Heavy industries like material handling are primary beneficiaries. This includes cranes, elevators, and conveyor systems. Energy recovery is significant in these applications.

Machine tool manufacturers also utilize its precision. Applications include CNC machines and automated production lines. Consistent performance is key here.

Winding and unwinding machines in paper and textile sectors benefit. Test benches and dynamometers leverage its control accuracy. These sectors require precise motion.

What are the key technical specifications for the 6SL3730-730-8BA3?

It has a substantial power rating of 235 kW. The nominal current capacity is 380 A. It operates on a 400 V power supply.

This unit is part of the robust SINAMICS S120 Cabinet series. It features an integrated Active Infeed Module (AIM). This allows for regenerative capabilities.

Its robust cabinet design ensures durability in harsh industrial environments. It is engineered for high-performance and reliability. It handles demanding applications effectively.

How is the Siemens 6SL3730-730-8BA3 commissioned?

Commissioning is performed using Siemens TIA Portal software. Motor data and control parameters are configured. Safety functions are also set up during this phase.

The drive needs to be connected to the control system via PROFINET/PROFIBUS. Network communication is established. Parameters are downloaded to the unit.

The AIM module requires specific wiring for energy feedback. Proper grounding and shielding are critical. System testing validates all configurations.

What safety considerations are important for this unit?

Always ensure the system is de-energized before maintenance. Follow proper lockout/tagout procedures. Qualified personnel should perform all work.

Emergency stop circuits must be correctly implemented. Overload and overcurrent protection are essential. Adhere strictly to local electrical codes and standards.

Regular visual inspections for damage or wear are advised. Ensure adequate ventilation around the cabinet. Maintain a clean operating environment.

How does this unit integrate with other Siemens automation components?

It seamlessly integrates with Siemens SIMOTICS motors. It communicates via industrial Ethernet protocols like PROFINET. This allows for unified control.

TIA Portal provides a single engineering environment. This simplifies programming and parameterization. It supports advanced diagnostics and data exchange.

This integration enables smart factory concepts. It supports IIoT applications for predictive maintenance. It enhances overall system connectivity.

What are common troubleshooting steps for this SINAMICS S120 unit?

Check power supply voltage and phase sequence first. Verify all motor and encoder connections. Ensure adequate cooling and ventilation.

Review fault codes displayed on the HMI or in TIA Portal. Consult the official Siemens documentation for specific error resolutions. Resetting the drive after fault resolution is common.

Inspect for any loose wiring or signs of component damage. Confirm that parameters are correctly set for the application. Address any communication errors between the drive and controller.

Can this unit be used in hazardous environments?

The standard cabinet is not designed for hazardous areas. Special enclosures or modifications may be required. Consult Siemens for specific hazardous area solutions.

Proper ventilation and temperature control are crucial. Avoid environments with excessive dust or corrosive substances. Ensure compliance with environmental ratings.

Always follow safety guidelines for hazardous locations. Use appropriate personal protective equipment. Risk assessments are mandatory.

What is the expected lifespan of the Siemens 6SL3730-730-8BA3?

With proper installation and maintenance, its lifespan is extensive. Siemens components are known for their durability. Lifespan depends on operating conditions and duty cycles.

Regular preventative maintenance extends operational life. This includes cleaning, checking connections, and firmware updates. Avoid exceeding rated specifications.

The modular design allows for component replacement if needed. This can prolong the overall system usability. It's an investment in long-term operational efficiency.