The Siemens 6ES7231-5PD32-0XB0 is a high-performance 4-channel thermocouple temperature measurement module designed for demanding industrial automation applications. This module offers exceptional accuracy, rapid response times, and robust diagnostics, making it an indispensable component for precise temperature monitoring in critical processes. Its key advantages lie in its multi-channel capability, superior noise immunity, and seamless integration within the SIMATIC S7-1200 platform, ensuring reliable operation in harsh environments. Technical parameters of note include its direct thermocouple input, high resolution, and diagnostic functions for wire breakage and overflow.

Siemens 6ES7231-5PD32-0XB0: Product Specifications

| Feature | Specification |

| :----------------------- | :------------------------------------------ |

| Product Type | Analog Input Module |

| Model Number | 6ES7231-5PD32-0XB0 |

| Number of Channels | 4 |

| Input Type | Thermocouple (Types B, E, J, K, L, N, R, S, T, U, W) |

| Resolution | 16-bit |

| Accuracy | Typically ±0.1% of full scale |

| Conversion Time | Approx. 720 ms per module |

| Supply Voltage | 24 V DC |

| Interface | PROFIBUS DP (integrated) |

| Diagnostic Functions | Wire Breakage, Overflow, Underflow |

| Ambient Temperature | -20°C to +60°C |

| Dimensions (W x H x D) | 45 mm x 100 mm x 75 mm |

| Degree of Protection | IP20 |

Core Features & Market Positioning

The Siemens 6ES7231-5PD32-0XB0 distinguishes itself through its comprehensive thermocouple type support, allowing for flexibility across a wide array of temperature sensing applications. Its 16-bit resolution delivers precise temperature readings, crucial for processes requiring tight control. The integrated PROFIBUS DP interface simplifies network integration, reducing cabling complexity and enhancing data transfer efficiency, a significant advantage in distributed control systems. Furthermore, the module's robust diagnostic capabilities, including wire breakage detection, proactively alert operators to potential sensor failures, minimizing unscheduled downtime and preventing costly process deviations. This combination of accuracy, versatility, and integrated diagnostics positions the 6ES7231-5PD32-0XB0 as a premium solution for high-integrity temperature measurement within the industrial automation market.

Key Application Scenarios

This thermocouple input module finds extensive application in industries where precise and reliable temperature monitoring is paramount. It is ideally suited for process control in the chemical and petrochemical sectors, monitoring reactor temperatures, distillation columns, and heat exchangers. In the manufacturing of plastics and rubber, the 6ES7231-5PD32-0XB0 is critical for controlling extrusion and molding temperatures, ensuring product quality and consistency. The food and beverage industry benefits from its accuracy in monitoring pasteurization, sterilization, and cooking processes. Furthermore, its robustness makes it suitable for use in power generation facilities, for monitoring turbine exhaust temperatures or boiler conditions, and in metal processing for controlling furnace temperatures and heat treatment cycles.

Practical System Integration Guidance

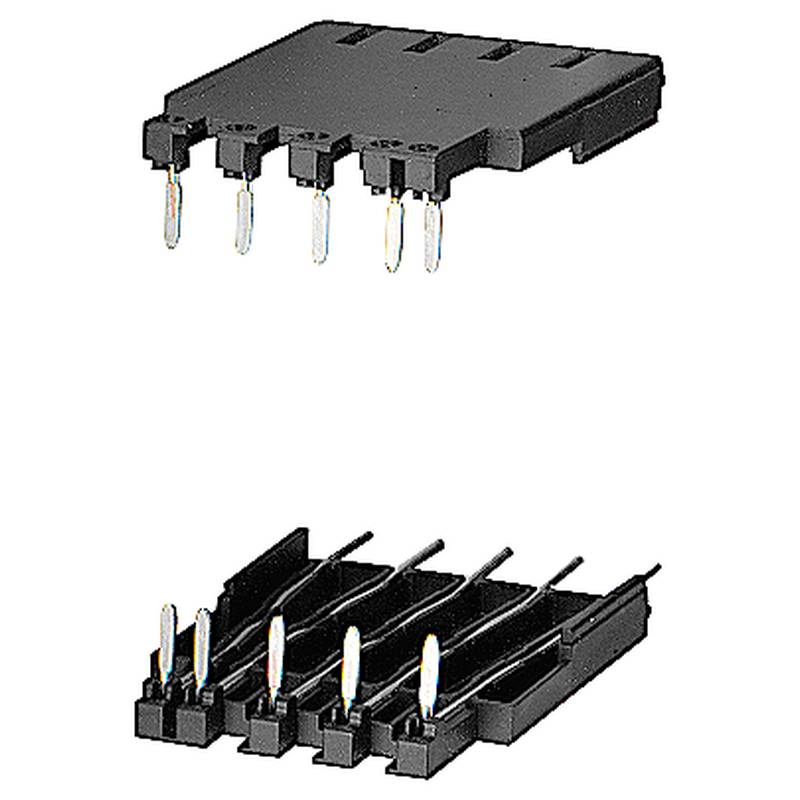

Integrating the Siemens 6ES7231-5PD32-0XB0 into a SIMATIC S7-1200 system is streamlined through the TIA Portal engineering software. Installation involves securely mounting the module onto a DIN rail and connecting the 24V DC supply. For thermocouple wiring, ensure correct polarity for each channel and use appropriate compensating cables to maintain signal integrity. The module supports various thermocouple types, which are configured in the TIA Portal hardware configuration. Programming involves reading the analog input values from the module's data blocks and implementing control logic based on these temperature readings. Diagnostic interrupts can be configured to alert the PLC to events like wire breakage, enabling rapid fault response.

Operation and Risk Mitigation

Safe operation of the Siemens 6ES7231-5PD32-0XB0 necessitates adherence to electrical safety standards and proper installation practices. Always ensure the power supply is de-energized before connecting or disconnecting the module. The module's IP20 rating indicates it should be installed in an enclosure to protect against physical contact and dust. Potential operational risks include incorrect thermocouple type selection, which leads to inaccurate readings, and improper wiring, causing signal loss or incorrect measurements. Fault codes and diagnostic messages within the TIA Portal provide crucial information for troubleshooting. For instance, a wire breakage diagnostic indicates an open circuit in the thermocouple or its wiring, requiring immediate inspection of the sensor and connections.

Scalability & Long-Term Value

The Siemens 6ES7231-5PD32-0XB0 offers significant long-term value through its compatibility with the broader SIMATIC S7-1200 ecosystem, facilitating system expansion. As processes evolve, additional I/O modules can be easily integrated to increase measurement points or control capabilities. Its PROFIBUS DP interface ensures seamless communication with other PROFIBUS-enabled devices, simplifying network upgrades and expansions. For users looking towards digitalization and the Industrial Internet of Things (IIoT), the data acquired by this module can be integrated into SCADA systems or cloud platforms for advanced analytics, predictive maintenance, and process optimization, extending its utility well into the future.

Frequently Asked Questions

What thermocouple types are supported by the Siemens 6ES7231-5PD32-0XB0?

This module supports a comprehensive range of standard thermocouple types including B, E, J, K, L, N, R, S, T, U, and W. This wide compatibility ensures flexibility for diverse industrial temperature measurement needs across various applications. Each type has a specific temperature range and characteristics suited for different environments and process requirements.

The selection of the correct thermocouple type is critical for accurate readings. Incorrect configuration can lead to significant measurement errors. Always consult the product manual for the specific temperature ranges and suitability of each thermocouple type for your intended application. Proper training on thermocouple types and their respective uses is advisable for personnel involved in system design and maintenance.

Referencing the module's technical documentation or TIA Portal hardware configuration will provide definitive details on supported types and their associated input ranges. Ensuring the thermocouple physically connected to the module matches the configured type is paramount for reliable operation and precise data acquisition.

How do I wire a thermocouple to the Siemens 6ES7231-5PD32-0XB0 module?

Wiring involves connecting the positive and negative terminals of the thermocouple to the corresponding inputs on the module. It is crucial to use appropriate compensating cables to connect the thermocouple to the terminal block, especially for longer distances, to maintain signal accuracy. Ensure correct polarity; reversing the wires will result in incorrect temperature readings or potentially a negative value.

The module's documentation or TIA Portal's hardware configuration will illustrate the specific terminal assignments for each of the four channels. Pay close attention to these diagrams to avoid miswiring. Proper strain relief and secure connections are also important to prevent intermittent faults or physical damage to the wiring.

For optimal performance, always use high-quality compensating extension wires designed for the specific thermocouple type being used. Shielded cables are recommended in environments with high electromagnetic interference (EMI) to prevent signal degradation and ensure the integrity of the temperature measurement.

What are the diagnostic capabilities of the 6ES7231-5PD32-0XB0 module?

The Siemens 6ES7231-5PD32-0XB0 features essential diagnostic functions to detect common faults. These include wire breakage detection, which alerts the system if a thermocouple connection is open-circuited. It also provides overflow and underflow diagnostics, indicating if the measured temperature exceeds or falls below the module's configured range.

These diagnostic signals can be configured as interrupts within the PLC program. This allows for immediate notification of faults to operators or for triggering automated safety responses, such as shutting down a process to prevent damage or ensure safety. Proactive detection of issues minimizes unscheduled downtime.

Troubleshooting these diagnostics typically involves inspecting the thermocouple itself, its wiring, and the connections to the module. The specific diagnostic status can be accessed through the module's I/O image in the PLC or via diagnostic tools within TIA Portal, providing valuable information for pinpointing the fault location.