The Siemens 6SL3210-1KE31-4AF1 G120 Safety Converter is engineered for demanding industrial environments, offering robust performance and integrated safety functions. This converter boasts a high-capacity 136A current rating and a powerful 75kW output, making it ideal for heavy-duty applications that require precise motor control and operational reliability. Its advanced design ensures efficient power conversion, enhanced system protection, and simplified integration into complex automation setups.

Product Specifications

| Parameter | Specification |

| :------------------------- | :------------------------------------------------ |

| Product Number | 6SL3210-1KE31-4AF1 |

| Series | SINAMICS G120 |

| Frame Size | FX (for PM250/PM350 power modules) |

| Rated Power (kW) | 75 |

| Rated Current (A) | 136 |

| Input Voltage | 380-480V 3-phase |

| Output Voltage | 3 AC, 400V (variable) |

| Safety Integrated | Yes (STO - Safe Torque Off) |

| Cooling Method | Air cooling |

| Protection Rating | IP20 |

| Dimensions (H x W x D) | Specific dimensions depend on control unit and power module pairing, but generally substantial for this power class. |

| Operating Temperature | -20°C to +50°C (derating may apply) |

Core Features & Market Positioning

The Siemens 6SL3210-1KE31-4AF1 differentiates itself through its robust construction and advanced safety features, specifically the integrated Safe Torque Off (STO) functionality. This inherent safety capability significantly reduces the complexity and cost of implementing machine safety standards, positioning it as a superior choice for applications where personnel protection is paramount. The SINAMICS G120 platform is renowned for its flexibility and high performance, and this specific model extends those benefits to heavy-duty sectors. Its ability to handle high power outputs while maintaining precise motor control underscores its premium market positioning for critical industrial processes.

Key Application Scenarios

This converter is ideally suited for heavy-duty motor control applications across various industries. Common use cases include powering large pumps and fans in chemical plants, material handling systems in warehouses, compressors in manufacturing facilities, and extruders in plastics processing. Its high power rating and reliability make it suitable for applications demanding continuous operation and significant torque, such as in mining operations or heavy construction machinery. The integrated safety functions are particularly valuable in environments where rapid shutdown is essential to prevent accidents.

Practical System Integration Guidance

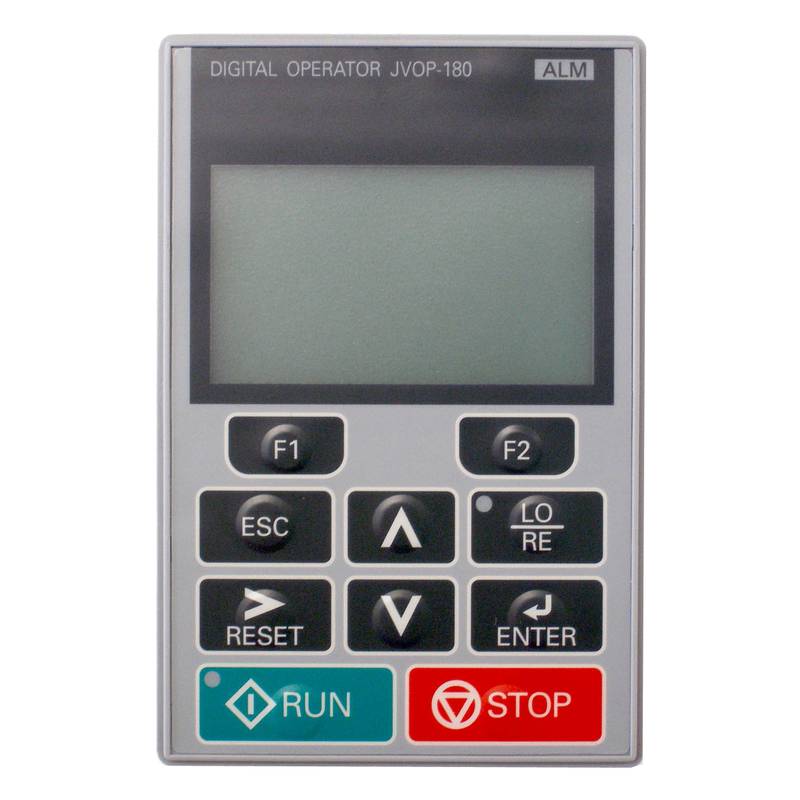

Integrating the Siemens 6SL3210-1KE31-4AF1 into an existing system involves careful consideration of power, control, and safety wiring. The converter requires a robust 380-480V three-phase power supply. For STO functionality, dedicated safety relay modules or safety PLCs must be connected to the designated safety terminals on the control unit. Parameterization is typically performed using Siemens' SIMATIC Digitalization Platform (TIA Portal) or a handheld operator panel (HMI), allowing for detailed configuration of motor data, control modes, and safety parameters. Ensuring proper grounding and ventilation is crucial for optimal performance and longevity.

Operation and Risk Mitigation

Operating the Siemens 6SL3210-1KE31-4AF1 requires adherence to its technical specifications and safety guidelines. Key operational considerations include ensuring the motor is correctly matched to the converter's power rating and environmental conditions. Risk mitigation is primarily addressed through the STO function, which effectively prevents the motor from generating torque when activated, thereby eliminating hazardous movements. Common troubleshooting may involve monitoring fault codes displayed on the operator panel. For instance, F001 indicates a general fault, while F007 might relate to an overcurrent condition, necessitating a review of motor load and parameter settings.

Scalability & Long-Term Value

The SINAMICS G120 platform, including the 6SL3210-1KE31-4AF1, offers significant scalability and long-term value through its modular design and compatibility with Siemens' broader automation ecosystem. It can be integrated into distributed control architectures or centralized systems within the TIA Portal, facilitating future expansion and upgrades. Compatibility with various industrial communication protocols (e.g., PROFINET, PROFIBUS) allows seamless integration with other intelligent devices and IIoT platforms for enhanced data acquisition and predictive maintenance strategies. This future-proofing ensures continued relevance and operational efficiency in evolving industrial landscapes.

FAQs

What is the primary advantage of the Siemens 6SL3210-1KE31-4AF1 G120 converter?

Its main benefit is the integrated Safe Torque Off (STO) capability. This feature enhances machine safety directly. It simplifies compliance with safety standards.

This integrated safety reduces the need for external safety components. It lowers overall system costs and complexity. This makes it ideal for safety-critical operations.

The converter also offers high power density and precise motor control. This combination makes it a versatile solution for demanding tasks. It ensures reliable operation in harsh industrial settings.

What are the key technical specifications for the Siemens 6SL3210-1KE31-4AF1?

This converter is rated for 75kW of power. It handles a maximum current of 136A. It operates on a 380-480V three-phase input.

The unit belongs to the SINAMICS G120 series. It utilizes the FX frame size for its power modules. This configuration is built for heavy-duty applications.

It features integrated safety with STO functionality. The cooling method is air cooling. Its protection rating is IP20.

Which industries commonly utilize the Siemens 6SL3210-1KE31-4AF1 converter?

Heavy industries like mining and manufacturing are prime users. It's employed in applications with large motors. This includes powering heavy machinery.

The converter is also vital in chemical processing. It drives large pumps, fans, and compressors. These systems require high reliability and power.

Material handling and logistics sectors benefit greatly. Think of large conveyor systems or automated warehouses. Its robust design suits these demanding environments.

How is the Siemens 6SL3210-1KE31-4AF1 converter installed and commissioned?

Installation requires proper electrical connections. Ensure correct wiring for power input and motor output. Follow wiring diagrams precisely for safety functions.

Commissioning involves parameter configuration. Use TIA Portal or an operator panel. Set motor data, control modes, and safety parameters.

A thorough system check is essential post-commissioning. Verify all functions, especially safety interlocks. Ensure smooth operation under load.

What safety features are included in the Siemens 6SL3210-1KE31-4AF1?

The standout safety feature is STO. Safe Torque Off prevents dangerous motor movement. It ensures personnel safety during maintenance or emergencies.

This integrated STO reduces external safety hardware. It simplifies safety circuit design and wiring. This lowers installation complexity and cost.

Other safety aspects include proper fault detection and diagnostics. The system monitors for anomalies. It alerts operators to potential hazards.

Can the Siemens 6SL3210-1KE31-4AF1 be integrated into a networked industrial system?

Yes, it integrates with Siemens' TIA Portal. This platform supports networking. It allows connection to PROFINET or PROFIBUS networks.

Network integration enables remote monitoring and control. It facilitates data exchange for IIoT applications. This enhances process visibility and optimization.

This connectivity allows for advanced diagnostics. It supports predictive maintenance strategies. It ensures seamless operation within a larger automation landscape.

What are the typical troubleshooting steps for common faults with this converter?

First, check the fault code displayed. Each code points to a specific issue. For example, overcurrent faults need load checks.

Inspect motor and wiring for damage or faults. Ensure correct parameter settings match the application. Verify the power supply is stable and within limits.

Consult the official Siemens manual for detailed fault code explanations. Perform systematic checks to isolate the root cause. Address the specific issue identified by the fault code.

What is the operational temperature range for this converter?

The converter operates reliably between -20°C and +50°C. This wide range suits many industrial environments. Always consider derating at higher temperatures.

Exceeding the temperature limit can cause issues. It may lead to reduced performance or component damage. Ensure adequate ventilation around the unit.

Proper thermal management is key to longevity. It maintains consistent performance. It prevents unexpected shutdowns due to heat.

How does the Siemens 6SL3210-1KE31-4AF1 contribute to long-term value?

Its modular design allows for future upgrades. This flexibility adapts to changing production needs. It extends the usable life of the equipment.

Compatibility with Siemens' automation portfolio is crucial. It integrates with newer systems and software. This ensures ongoing support and technological relevance.

Robust construction and reliable performance reduce downtime. This minimizes maintenance costs. It maximizes operational efficiency over time.

What is the protection rating of the Siemens 6SL3210-1KE31-4AF1 converter?

The converter has an IP20 protection rating. This means it is protected against solid objects. It is specifically protected against objects larger than 12.5mm.

However, it is not protected against water ingress. Therefore, it must be installed in a clean, dry environment. Avoid areas with high humidity or dust.

Proper enclosure or installation is recommended. This ensures it meets its intended protection level. It safeguards the converter from environmental contaminants.