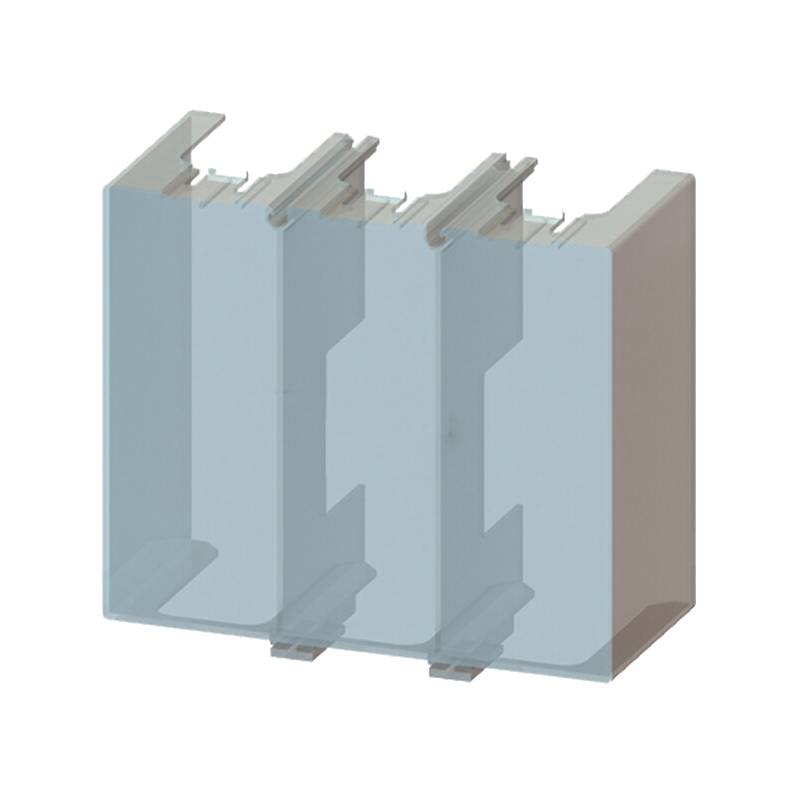

The Siemens 6SL3220-1YD26-0CB0 G120XA Industrial Grade Filter Drive System represents a robust and efficient solution for demanding industrial applications. This system boasts a 25A continuous current rating and an 11kW power output, engineered for superior performance and reliability in harsh environments. Its integrated filter design significantly reduces electromagnetic interference (EMI), ensuring clean power delivery and protecting sensitive control systems. The G120XA series is recognized for its advanced control capabilities, energy efficiency, and ease of integration, making it a preferred choice for machinery manufacturers and system integrators seeking high-performance motor control.

Product Specifications

| Parameter | Value |

| :--------------------- | :------------------------------------- |

| Product Number | 6SL3220-1YD26-0CB0 |

| Series | SINAMICS G120X |

| Type | Filter Drive System |

| Rated Current (A) | 25A |

| Rated Power (kW) | 11kW |

| Input Voltage | 380-480V AC, 3-Phase |

| Output Voltage | 0-480V AC, 3-Phase |

| Protection Class | IP20 |

| Operating Temperature | -20°C to +50°C |

| Dimensions (H x W x D) | (Varies by frame size; refer to manual) |

| Communication | PROFINET, PROFIBUS (optional modules) |

Core Features & Market Positioning

The Siemens 6SL3220-1YD26-0CB0 distinguishes itself through its integrated input filter, a critical component for minimizing harmonic distortion and complying with stringent EMC directives in industrial settings. This feature simplifies system design by eliminating the need for external filters, reducing installation time and cost. The G120XA platform is built upon Siemens' renowned SINAMICS drive technology, offering advanced vector control algorithms for precise motor speed and torque management, even under fluctuating load conditions. Its rugged construction and wide operating temperature range position it as an industrial-grade solution, capable of withstanding challenging operational environments found in manufacturing, material handling, and infrastructure projects. The system's inherent energy-saving functions, such as low-loss power modules and efficient motor control, contribute to reduced operating expenses, further enhancing its market appeal.

Key Application Scenarios

This drive system is ideally suited for a broad spectrum of industrial automation tasks requiring reliable and precise motor control. Common applications include variable speed drives for pumps and fans in building services and water treatment plants, where energy efficiency and EMI reduction are paramount. In manufacturing environments, it excels in controlling conveyor systems, extruders, and processing machinery where consistent torque and speed are essential for product quality. The system's robustness also makes it suitable for use in material handling equipment, such as cranes and hoists, and in the packaging industry for precise motion control of filling and sealing machines. Its compatibility with various industrial communication protocols facilitates seamless integration into SCADA and DCS systems for centralized monitoring and control.

Practical System Integration Guidance

Integrating the Siemens 6SL3220-1YD26-0CB0 into existing or new control architectures is facilitated by its modular design and comprehensive parameterization options. Ensure proper grounding and shielding of motor and control cables to maximize the effectiveness of the integrated EMI filter. Terminal connections should be made according to the wiring diagrams provided in the Siemens G120XA operating instructions, paying close attention to power, control, and communication interfaces. Commissioning typically involves initial parameter setup via the operator panel or a connected engineering tool like the TIA Portal. Key parameters to configure include motor data, control mode (e.g., V/f control, vector control), and safety functions. For communication integration, install the appropriate communication module (e.g., PROFINET, PROFIBUS) and configure network addressing and diagnostic settings.

Operation and Risk Mitigation

Safe operation of the Siemens 6SL3220-1YD26-0CB0 requires adherence to established electrical safety practices and the manufacturer's guidelines. Ensure all personnel are qualified and aware of the potential hazards associated with variable frequency drives, including stored energy in DC link capacitors even after power disconnection. Implement proper lockout/tagout procedures during maintenance. The system offers built-in protection functions such as overload, overvoltage, undervoltage, and short-circuit protection, which should be correctly parameterized to prevent equipment damage and ensure personnel safety. Consult the product manual for a comprehensive list of fault codes and their corresponding troubleshooting steps. Common error codes like F0001 (Overcurrent) or F0002 (Overtemperature) typically indicate issues with motor load, cable connections, or ambient conditions.

Scalability & Long-Term Value

The Siemens 6SL3220-1YD26-0CB0 G120XA drive system offers significant long-term value through its scalability and integration capabilities with broader industrial automation platforms. Its compatibility with the SINAMICS family and Siemens' TIA Portal allows for seamless integration into larger automation projects, enabling centralized engineering and diagnostics. The availability of various communication modules ensures adaptability to evolving network standards, including industrial Ethernet protocols, supporting the transition towards Industry 4.0 and Industrial Internet of Things (IIoT) concepts. Software updates and firmware upgrades are periodically released by Siemens, providing opportunities to enhance performance, add new functionalities, and maintain optimal system efficiency throughout its lifecycle. This forward-compatibility ensures the drive system remains a valuable asset for years to come.

Frequently Asked Questions

What is the primary advantage of the Siemens 6SL3220-1YD26-0CB0 filter drive system?

Its integrated input filter significantly reduces electromagnetic interference (EMI) and harmonic distortion. This compliance with EMC standards simplifies system design and installation.

The system ensures clean power delivery, protecting connected equipment and control systems from electrical noise. It's engineered for reliable performance in environments with sensitive electronics.

This feature eliminates the need for external filters, saving valuable panel space, installation labor, and overall system cost. It streamlines the overall automation solution.

How does the Siemens 6SL3220-1YD26-0CB0 handle different motor types and loads?

This drive supports advanced vector control algorithms for precise motor speed and torque regulation. It adapts dynamically to changing load conditions, ensuring optimal performance.

The system is designed to efficiently control a wide range of AC induction motors and permanent magnet synchronous motors. Its flexibility accommodates various application requirements.

Parameterization allows for fine-tuning of motor characteristics and load dynamics, maximizing efficiency and responsiveness across diverse operational scenarios.

What are the typical installation requirements for this drive system?

Proper electrical grounding and shielding of all associated cables are crucial for optimal EMI reduction. Follow strict wiring diagrams for power, control, and communication lines.

Mount the unit in a well-ventilated enclosure to maintain optimal operating temperatures, especially during high-load cycles. Adhere to clearance specifications.

Ensure all safety protocols, including lockout/tagout, are followed before and during installation and maintenance procedures. Qualified personnel must perform these tasks.

Can this drive be integrated into existing Siemens automation systems?

Yes, the drive is part of the SINAMICS G120X platform and integrates seamlessly with Siemens' TIA Portal. This allows for unified engineering and diagnostics.

It supports standard industrial communication protocols like PROFINET and PROFIBUS via optional modules. This facilitates easy network integration.

Compatibility with other Siemens components and platforms ensures a scalable and cohesive automation solution for complex projects.

What are common troubleshooting steps for error codes on the 6SL3220-1YD26-0CB0?

Consult the official Siemens G120XA operating manual for specific fault code descriptions and recommended actions. Error codes provide direct diagnostic information.

For common errors like F0001 (Overcurrent), check motor load, cable integrity, and ensure correct motor data is parameterized. Verify supply voltage.

Persistent issues may require checking internal component health or contacting Siemens technical support for advanced diagnostics and potential hardware inspection.

How energy-efficient is the Siemens 6SL3220-1YD26-0CB0 drive?

The drive employs low-loss power modules and advanced control algorithms to minimize energy consumption. It optimizes motor operation for efficiency.

Its variable speed control capability allows matching motor output precisely to demand, significantly reducing energy usage compared to fixed-speed systems. This is key for pumps and fans.

Energy-saving functions and efficient cooling design contribute to lower operational costs and a reduced environmental footprint over the product's lifespan.

What protection features are included in this drive system?

It incorporates comprehensive protection against overload, overvoltage, undervoltage, and short circuits. These safeguard both the drive and connected equipment.

The system also includes thermal monitoring and protection for the motor and the drive itself, preventing damage from excessive heat buildup.

Additional safety functions can be parameterized, such as safe torque off (STO), enhancing personnel and system safety during unexpected events.

What is the typical communication interface for this drive?

The drive typically supports communication via PROFINET and PROFIBUS when equipped with appropriate optional communication modules. These are common industrial fieldbuses.

This allows for integration into distributed control systems (DCS) and programmable logic controllers (PLCs) for remote monitoring and control.

The chosen communication protocol influences data exchange capabilities, diagnostic features, and network topology possibilities within the automation architecture.

Is the Siemens 6SL3220-1YD26-0CB0 suitable for outdoor or harsh environments?

While rated IP20, meaning it offers protection against solid objects larger than 12.5mm and no protection against water, it is built with industrial-grade components for demanding conditions.

For applications requiring higher ingress protection (IP ratings) against dust or water, it must be installed within a suitable enclosure that meets the environmental demands.

The wide operating temperature range of -20°C to +50°C makes it robust for various industrial ambient conditions when properly housed.

What is the warranty period for this Siemens industrial drive?

Siemens typically provides a standard warranty for its industrial automation products, which usually covers defects in materials and workmanship. The exact duration may vary by region and specific sales agreement.

It is recommended to consult the official product documentation or contact your Siemens sales representative for definitive warranty terms and conditions applicable to your purchase.

Proper installation, operation within specified parameters, and adherence to maintenance schedules are often prerequisites for warranty claims.