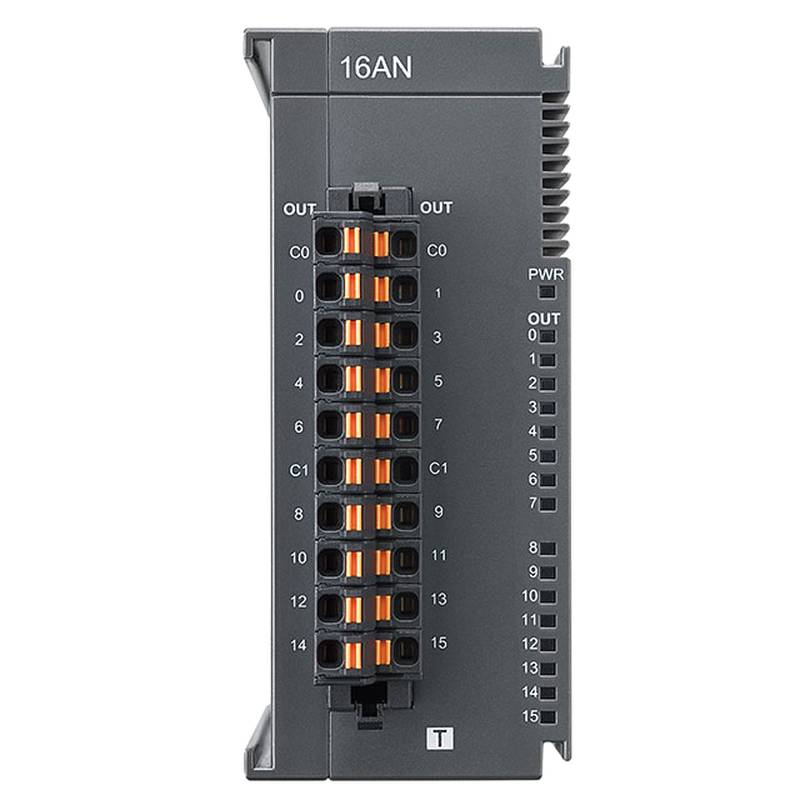

The Delta AS16AN01T-A 16-point Transistor Output Expansion Module offers a robust solution for extending the I/O capabilities of Delta's DVP series Programmable Logic Controllers (PLCs). This module is engineered for demanding industrial environments, providing 16 high-speed transistor outputs for precise control of actuators, motors, and other output devices. Its compact design and DIN-rail mountability facilitate straightforward integration into existing control panels. Key technical specifications include a voltage rating of 24VDC for its outputs, a maximum output current of 0.5A per point, and an impressive response time, ensuring efficient operation in high-frequency applications.

Product Specifications

| Feature | Specification |

| :---------------------- | :--------------------------------------------- |

| Module Type | Transistor Output Expansion Module |

| Number of Outputs | 16 points |

| Output Type | NPN (Sinking) Transistor |

| Voltage Rating (Output) | 24VDC |

| Max. Output Current | 0.5A per point |

| Common Voltage | 24VDC |

| Response Time | Max. 10µs |

| Power Consumption | Approx. 2W |

| Dimensions (W x H x D) | 57mm x 90mm x 65mm |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to 70°C |

| Mounting | DIN-rail |

| Compatibility | Delta DVP-ES2, DVP-EX2, DVP-EC2, DVP-SS2 series |

Core Features & Market Positioning

The Delta AS16AN01T-A distinguishes itself through its high-speed switching capabilities, making it an ideal choice for applications requiring rapid response times, such as packaging machinery, material handling systems, and high-frequency pulse generation. Its NPN sinking output configuration offers flexibility in wiring and component selection for output devices. Positioned as a reliable and cost-effective expansion solution, it directly addresses the growing need for increased I/O density in automated manufacturing without necessitating the upgrade to a more powerful, and expensive, PLC base unit. The module's robust build quality ensures consistent performance even under continuous operation in harsh industrial settings, a key differentiator in its market segment.

Key Application Scenarios

This transistor output expansion module finds extensive use in diverse automation tasks. In the food and beverage industry, it is crucial for controlling conveyors, filling machines, and labeling equipment where precise timing and high-speed actuation are paramount. The textile industry benefits from its rapid response for controlling high-speed looms and winding machinery. Furthermore, in general manufacturing, the AS16AN01T-A is employed in robotic cell automation, pick-and-place mechanisms, and sophisticated sorting systems that demand accurate and swift output signal delivery. Its suitability for pulse width modulation (PWM) applications also opens doors for precise motor speed control.

Practical System Integration Guidance

Integrating the Delta AS16AN01T-A into a Delta DVP PLC system is a streamlined process. Connection to the PLC is typically achieved via a dedicated expansion cable, ensuring reliable communication. Wiring of the 16 transistor outputs requires careful attention to the NPN configuration; the common terminal should be connected to the negative terminal (0V) of the 24VDC power supply, and the output devices should be connected between the output terminals and the positive terminal (+24VDC) of the power supply. Configuration within the PLC programming software, such as Delta's WPLSoft, involves simply assigning the I/O addresses for the new expansion module, allowing for intuitive control logic development.

Operation and Risk Mitigation

Safe operation of the Delta AS16AN01T-A hinges on adhering to its specified voltage and current ratings to prevent component damage and ensure system reliability. Overloading any of the 16 transistor outputs beyond their 0.5A limit can lead to premature failure. It is critical to ensure proper grounding of the PLC and the output devices to mitigate electrical noise and ground loops, which can interfere with control signals. Implementing appropriate overcurrent protection, such as fuses or circuit breakers, for the output circuits is a standard safety practice. While the module is designed for industrial robustness, avoiding exposure to excessive moisture, corrosive atmospheres, and extreme temperatures outside its operating range will significantly prolong its service life.

Scalability & Long-Term Value

The AS16AN01T-A module exemplifies scalability within the Delta DVP ecosystem. It allows users to incrementally expand their PLC's output capacity as automation requirements grow, avoiding the need for a complete system overhaul. Its compatibility with various Delta DVP series PLCs ensures that existing investments in Delta hardware and software are preserved. For facilities embracing Industry 4.0 initiatives, the high-speed transistor outputs can be leveraged for advanced data acquisition and control, feeding real-time operational data into supervisory control and data acquisition (SCADA) systems or Manufacturing Execution Systems (MES) for enhanced monitoring, analysis, and optimization.

Frequently Asked Questions (FAQs)

What are the primary advantages of using the Delta AS16AN01T-A?

This module offers high-speed switching capabilities crucial for demanding applications, ensuring rapid response times. It provides 16 additional transistor outputs, significantly expanding a PLC's control capacity without requiring a larger base unit. Its NPN sinking configuration offers wiring flexibility and broad compatibility with various output devices.

What is the maximum current rating for each transistor output on the AS16AN01T-A?

Each individual transistor output on the Delta AS16AN01T-A is rated for a maximum continuous current of 0.5 Amperes (A). Exceeding this limit can cause damage to the output transistor and potentially lead to module failure. It's essential to select output devices that operate well within this specification.

How do I wire the transistor outputs for an NPN (sinking) configuration?

For an NPN sinking configuration, connect the common terminal of the AS16AN01T-A to the negative (0V) terminal of your 24VDC power supply. Then, connect your output devices (e.g., solenoids, indicator lights) between the positive (+24VDC) terminal of the power supply and the respective output terminals of the expansion module. When the output is energized, current flows from the output device, through the device, and into the module's output transistor to ground.