The DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX 7.5kW IP55 Variable Frequency Drive (VFD) represents a pinnacle of industrial automation, engineered for demanding applications requiring precise motor control, robust performance, and exceptional energy efficiency. This three-phase, 480V VFD boasts a 7.5kW power rating and an IP55 enclosure, ensuring reliable operation in harsh environments. Its advanced features, including integrated harmonic mitigation and a user-friendly interface, position it as a superior choice for optimizing pump, fan, and general machinery performance across various industrial sectors.

Product Specifications

| Parameter | Value |

| :-------------------- | :----------------------------------------- |

| Model Number | FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX |

| Power Rating | 7.5 kW |

| Voltage | 480V (Three Phase) |

| Enclosure | IP55 |

| Protection Class | IP55 |

| Control Type | Variable Frequency Drive (VFD) |

| Manufacturer | Danfoss |

| Series | FC 301 |

Core Features & Market Positioning

The DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX distinguishes itself through its advanced control algorithms, offering superior motor performance and energy savings. Its integrated harmonic mitigation capabilities significantly reduce harmonic distortion, a common issue in VFD installations, thereby improving power quality and safeguarding other connected equipment. This focus on power quality and efficiency, coupled with Danfoss's reputation for reliability, positions the FC 301 series as a premium solution for industries prioritizing operational excellence and reduced energy expenditure. The robust IP55 enclosure further enhances its market appeal by guaranteeing protection against dust ingress and low-pressure water jets, making it suitable for challenging industrial settings.

Key Application Scenarios

This VFD is exceptionally well-suited for a broad spectrum of industrial applications where precise motor speed control and energy optimization are paramount. It excels in driving pumps in water and wastewater treatment plants, where variable speed operation directly translates to significant energy savings and reduced wear on mechanical components. In HVAC systems, the FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX effectively controls fans and compressors, maintaining desired environmental conditions while minimizing energy consumption. Beyond these, its versatility makes it an ideal choice for conveyor systems, mixers, extruders, and other general industrial machinery requiring dynamic speed adjustment.

Practical System Integration Guidance

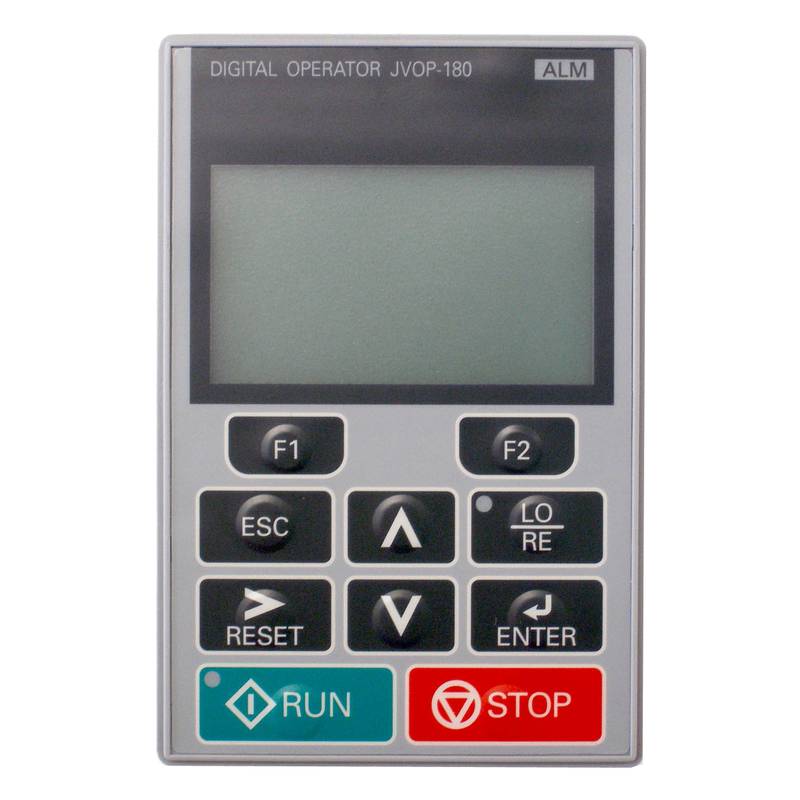

Integrating the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX into existing systems is streamlined by its user-friendly design and comprehensive documentation. Proper electrical installation is critical, adhering to local electrical codes and standards for three-phase power connections. The VFD should be installed in a location that allows for adequate ventilation to maintain its operating temperature within specified limits, especially given its IP55 rating which implies it can withstand some environmental challenges but still requires proper thermal management. For initial setup, users can leverage the intuitive control panel and digital displays to configure motor parameters, set speed references, and define operational limits. Advanced programming capabilities allow for custom logic, such as timed operations or interlocks with other machinery, further enhancing system automation and efficiency.

Operation and Risk Mitigation

Safe operation of the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX necessitates adherence to established safety protocols. Always ensure power is disconnected and locked out before performing any wiring or maintenance. The VFD's internal components can store high voltages even after power is removed, posing a shock hazard. Understanding common fault codes is crucial for efficient troubleshooting. For instance, overcurrent faults (often indicated by specific error codes) might point to motor issues, excessive load, or incorrect parameter settings, while under-voltage faults could signal power supply problems. Regular inspection of connections and ensuring the enclosure remains sealed are key to preventing ingress of contaminants that could lead to operational failures.

Scalability & Long-Term Value

The FC 301 series, including the FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX, is designed with scalability and long-term value in mind. Its modular design can accommodate various option modules, allowing for expanded communication capabilities (e.g., Profibus, Modbus TCP) or additional I/O, facilitating integration into advanced automation architectures and the Industrial Internet of Things (IIoT). This compatibility ensures that the VFD can evolve with a facility's automation strategy, protecting the initial investment. Furthermore, the inherent energy savings achieved through precise motor control contribute to a rapid return on investment and ongoing operational cost reductions, enhancing the overall long-term economic value of deploying this VFD.

FAQs

What are the primary benefits of using the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX?

This VFD offers significant energy savings through precise motor speed control. It enhances operational efficiency by providing accurate and stable motor performance.

Its robust IP55 enclosure ensures reliable operation even in challenging industrial environments. It also features integrated harmonic mitigation for improved power quality.

The advanced control features reduce mechanical stress on equipment, leading to extended component lifespan and reduced maintenance costs. This results in a lower total cost of ownership.

How do I properly install the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX?

Ensure the VFD is mounted in a clean, dry area with adequate ventilation to prevent overheating. Adhere strictly to all local electrical codes and Danfoss's installation manual for wiring safety.

Connect the three-phase incoming power and motor leads according to the specified terminal designations. Ground the VFD and motor properly to prevent electrical hazards.

Before powering up, verify all connections and confirm motor parameters are correctly entered into the VFD's setup menu. Follow the commissioning procedure outlined in the user manual.

What are common fault codes for the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX and how do I address them?

Common faults include overcurrent (OC), overvoltage (OV), and undervoltage (UV). OC faults typically indicate a motor issue or overload; check the motor and load.

UV faults can signal problems with the incoming power supply; verify the power source stability and connections. OV faults may arise during deceleration; adjust ramp times or check for regenerative braking issues.

Consult the product's technical documentation for a complete list of fault codes and their specific troubleshooting steps. Proper diagnosis based on the displayed code is key to resolution.

What type of motor is compatible with the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX?

This VFD is designed to control standard three-phase induction motors. It is compatible with motors rated for 480V operation.

Ensure the motor's nameplate data, such as power rating, full-load current, and speed, are accurately configured within the VFD parameters. This ensures optimal performance and protection.

The VFD can be used with various motor types, including standard asynchronous motors. Always confirm compatibility with specific motor designs if using non-standard motor configurations.

What is the power rating and voltage of the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX?

The VFD has a power rating of 7.5 kW. This is equivalent to approximately 10 horsepower.

It operates on a three-phase 480V power supply. This voltage is standard for many industrial applications in North America and other regions.

The combination of 7.5kW and 480V makes it suitable for a wide range of medium-duty industrial motor applications. It offers a good balance of power and efficiency.

Can the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX be used in outdoor or dusty environments?

Yes, the FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX features an IP55 enclosure. This rating means it is protected against dust ingress.

The IP55 rating also indicates protection against water jets from any direction. This allows for installation in environments where it may be exposed to occasional moisture or cleaning.

However, direct or prolonged exposure to harsh weather elements like heavy rain or extreme temperatures may still require additional protective measures or enclosure considerations. Always check specific environmental limits.

What communication protocols does this VFD support for integration into automation systems?

This specific model, with the "H2XGCXXXSXXXXAXBXCXXXXDX" suffix, often implies support for common industrial fieldbuses via optional modules. These typically include protocols like Profibus DP, DeviceNet, or Modbus TCP/IP.

To confirm the exact supported protocols, one would usually check the ordering code details or consult the product's specification sheet for available option cards. These modules are generally plug-in.

Integration into SCADA or PLC systems is a key feature, enabling remote monitoring, control, and data logging, crucial for modern industrial automation and IIoT initiatives.

What are the key advantages of the FC 301 series VFDs over older models or competitors?

The FC 301 series boasts enhanced energy efficiency algorithms and advanced motor control capabilities, optimizing performance and reducing power consumption. It offers a user-friendly interface and simpler commissioning process.

Key competitive advantages include superior harmonic mitigation, which reduces the need for external filters and improves overall system power quality. The robust design ensures reliability in demanding industrial settings.

These drives often provide greater flexibility through modular options for communication and I/O, facilitating easier integration and future upgrades compared to older or less configurable competitor products.

How does the IP55 rating benefit the operation of this VFD?

The IP55 rating signifies robust protection against dust and water, allowing the VFD to operate reliably in a variety of industrial environments that might otherwise be too harsh. It prevents the ingress of harmful dust particles.

This protection against water jets means that occasional cleaning with water or exposure to minor splashes will not compromise the VFD's functionality, increasing its suitability for process-critical areas.

Overall, the IP55 enclosure enhances the longevity and reduces the risk of premature failure due to environmental factors, contributing to a more dependable and lower-maintenance industrial operation.

What is the typical lifespan and maintenance requirement for the DANFOSS FC-301P7K5T4E55H2XGCXXXSXXXXAXBXCXXXXDX?

With proper installation and operation within specified environmental limits, these VFDs are designed for a long operational lifespan, often exceeding 10-15 years. Regular maintenance is minimal.

Key maintenance involves periodic inspection of the enclosure seal integrity, ensuring ventilation openings are clear of debris, and checking electrical connections for tightness. Filter replacement might be needed over time depending on environmental dust levels.

Preventive maintenance, such as monitoring operating temperatures and checking for any unusual noises or vibrations, can help identify potential issues early, further extending the VFD's service life and preventing unexpected downtime.