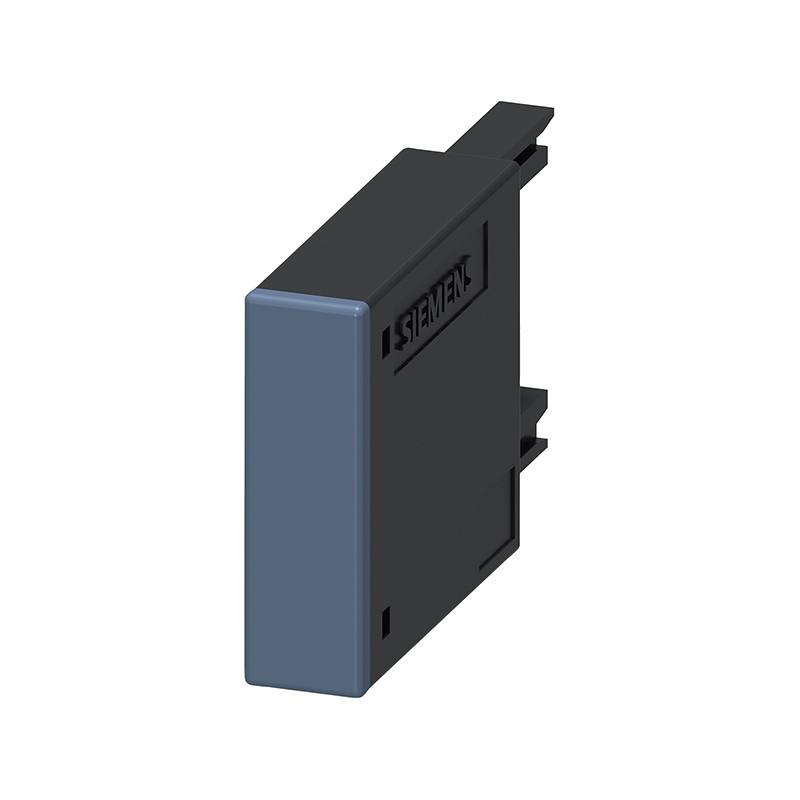

The SIEMENS JJY:023434020003 SINAMICS G120 Braking Resistor is a critical component designed for power module FSD, offering robust performance for applications requiring dynamic braking. With a power rating supporting both 9.25kW and 18.5kW applications, this resistor efficiently dissipates excess energy generated during deceleration, thereby protecting the drive system and ensuring operational stability. Its integration within the SINAMICS G120 platform underscores Siemens' commitment to modularity and high-performance motor control solutions.

Product Specifications

| Parameter | Value |

| :--------------------------- | :-------------------------- |

| Manufacturer | Siemens |

| Product Series | SINAMICS G120 |

| Component Type | Braking Resistor |

| Model Number | JJY:023434020003 |

| Compatibility | Power Module FSD |

| Rated Power (Lower Range) | 9.25 kW |

| Rated Power (Upper Range) | 18.5 kW |

| Application | Energy Dissipation (Braking) |

| Protection Type | IP20 (Typical for G120) |

| Operating Temperature Range | -20°C to +50°C (Typical) |

| Voltage Compatibility | Varies with G120 module |

| Dimensions (approximate) | Varies with module variant |

Core Features & Market Positioning

The SIEMENS JJY:023434020003 stands out due to its seamless integration with the SINAMICS G120 series, a widely recognized standard in industrial automation for its flexibility and robust control capabilities. This braking resistor is engineered to meet the demanding requirements of modern industrial processes where rapid and controlled stopping of motor loads is essential. Its core advantage lies in its ability to precisely manage kinetic energy, preventing overvoltage within the drive system during regenerative braking scenarios. This feature is crucial for maintaining the longevity of power semiconductors and ensuring uninterrupted operation in critical applications, positioning it as a premium solution for system integrators and end-users prioritizing reliability and system protection.

Key Application Scenarios

This SIEMENS braking resistor is ideally suited for applications involving frequent motor starts, stops, and speed reversals, where significant kinetic energy needs to be dissipated. Common industrial segments benefiting from its robust performance include material handling systems, such as conveyors and cranes, where precise load positioning and controlled deceleration are paramount. Manufacturing automation, including automated guided vehicles (AGVs) and robotic arms, also leverages this component to ensure smooth and safe operation. Furthermore, in the processing industries, like packaging and printing machines, where rapid cycle times and accurate stopping are critical, the SINAMICS G120 braking resistor contributes to increased throughput and reduced wear on mechanical components.

Practical System Integration Guidance

Integrating the SIEMENS JJY:023434020003 braking resistor into a SINAMICS G120 drive system involves straightforward wiring procedures. The resistor is typically connected to the DC bus terminals of the compatible power module (FSD). It is imperative to ensure that the resistor's power rating aligns with the specific application's braking energy requirements and the power module's capabilities. For optimal performance and safety, the resistor should be mounted in a well-ventilated area, adhering to Siemens' recommended clearance distances to prevent overheating. Configuration within the SINAMICS drive's parameters is essential; specifically, the braking chopper and resistor utilization settings need to be enabled and correctly adjusted within the control unit to activate the braking function when the DC bus voltage exceeds the predefined threshold.

Operation and Risk Mitigation

Proper operation of the SIEMENS JJY:023434020003 braking resistor is critical for preventing potential equipment damage and ensuring personnel safety. The resistor is activated automatically by the SINAMICS G120 drive's control logic when the DC bus voltage rises above a safe operating limit, typically during regenerative braking. This prevents overvoltage faults that could damage the power module's electronic components. Risks associated with its operation primarily stem from improper installation or parameterization. Overheating can occur if ventilation is inadequate or if the resistor is undersized for the application's braking duty cycle. It is crucial to consult the SINAMICS G120 operating manual for specific fault codes related to braking resistors, such as "Overvoltage" or "Braking Resistor Fault," which may indicate a need for system inspection or parameter adjustment.

Scalability & Long-Term Value

The SIEMENS JJY:023434020003 braking resistor offers significant long-term value through its inherent scalability and compatibility within the broader SINAMICS ecosystem. As part of the modular G120 platform, it allows for easy upgrades or modifications to the drive system without requiring a complete overhaul. This backward and forward compatibility ensures that investments in Siemens automation technology remain relevant and adaptable to evolving industrial needs. Furthermore, the integration capabilities of the SINAMICS G120, including its potential for connectivity with Industrial Internet of Things (IIoT) platforms and digital twin solutions, enhance the long-term value proposition. By enabling remote monitoring, predictive maintenance, and performance optimization, the braking resistor contributes to overall system efficiency and reduced operational costs over the lifecycle of the equipment.

Frequently Asked Questions (FAQs)

What is the primary function of the SIEMENS JJY:023434020003 braking resistor?

Its main role is to dissipate excess electrical energy generated during motor deceleration. This energy, known as regenerative energy, is converted into heat by the resistor.

This process protects the drive system from overvoltage conditions. It ensures the reliable operation of the SINAMICS G120 power module.

The resistor is vital for applications requiring quick and controlled stops. It prevents damage to drive components and prolongs system lifespan.

How do I determine if I need a braking resistor for my SINAMICS G120 drive?

Assess your application's braking requirements and duty cycle. Frequent or rapid stops often necessitate a braking resistor.

Check the drive's DC bus voltage during deceleration. If it frequently exceeds safe limits, a resistor is recommended.

Consult Siemens documentation for power module FSD and G120 series. They provide guidelines on when braking resistors are required.

What are the key technical specifications of the SIEMENS JJY:023434020003?

This resistor is designed for Siemens SINAMICS G120 power modules, specifically FSD. It supports power ratings for both 9.25kW and 18.5kW applications.

It effectively handles the energy dissipation during braking. The precise resistance value and power dissipation capacity are critical.

Its integration ensures efficient management of regenerative energy, contributing to system stability.

Can the SIEMENS JJY:023434020003 be used with other Siemens drive series?

This specific braking resistor, model JJY:023434020003, is designed for the SINAMICS G120 power module FSD. Its compatibility is explicitly tied to this platform.

While other Siemens drives may use braking resistors, this exact part number is tailored for the G120's architecture and power requirements. Always verify compatibility.

Using an incompatible resistor can lead to system failure, damage, or safety hazards. Always adhere to manufacturer specifications.

What are the installation considerations for this braking resistor?

Install the resistor in a well-ventilated area to facilitate heat dissipation. Maintain required clearances around the unit.

Connect the resistor to the designated DC bus terminals on the FSD power module. Ensure secure connections to prevent electrical issues.

Follow Siemens' mounting and wiring guidelines rigorously. Proper installation is crucial for performance and safety.

How is the braking resistor configured within the SINAMICS G120 drive?

Braking functionality is enabled and configured through the drive's control parameters. Key settings involve the braking chopper and resistor activation thresholds.

The drive control unit monitors the DC bus voltage. When it exceeds the programmed limit, the braking chopper activates, connecting the resistor.

Accurate parameterization ensures efficient energy dissipation and prevents overvoltage faults.

What kind of faults might indicate a problem with the braking resistor?

Overvoltage faults on the DC bus are a common indicator. This suggests the resistor is not adequately dissipating regenerative energy.

Braking resistor specific error codes, such as those related to thermal overload or open circuits, may appear. Consult the SINAMICS G120 fault list.

Such faults require immediate investigation into the resistor's condition and system configuration.

What is the typical lifespan of a SINAMICS G120 braking resistor?

The lifespan is dependent on the application's duty cycle and operating conditions. Frequent, heavy braking will reduce its lifespan.

With proper installation, configuration, and within its rated capacity, these resistors can last many years. Regular inspection is advised.

Preventing over-application and ensuring adequate cooling are key to maximizing operational longevity.

What is the resistance value of the SIEMENS JJY:023434020003?

The precise resistance value is a critical technical specification for proper operation. This data is typically found in the detailed product datasheet.

This resistor is designed to work with specific power ratings and voltage levels of the FSD power module. The resistance is matched to these parameters.

System integrators must refer to the official Siemens documentation for the exact Ohm rating to ensure correct system design.

Where can I find the official datasheet for the SIEMENS JJY:023434020003?

The official datasheet can usually be obtained from the Siemens Industry Online Support (SIOS) portal. This is Siemens' central repository for technical documentation.

Alternatively, authorized Siemens distributors or sales representatives can provide product documentation. Searching the Siemens website with the exact part number is also effective.

Always ensure you are referencing the most current version of the datasheet for accurate technical details.