The Delta DVP40ES200R is a medium-sized automation control CPU PLC system designed for efficient and reliable sequential control in various industrial applications. This PLC offers a robust feature set, making it a competitive choice for users seeking a balance of performance, functionality, and cost-effectiveness.

Product Specifications

| Specification | Value |

| :------------------------ | :-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- |

| MPU Points | 16 / 20 / 24 / 32 / 40 / 60 |

| Program Capacity | 16k steps |

| Communication Ports | 1 x RS-232, 2 x RS-485 (independent Master/Slave operation) |

| Max. I/O Points | 256 input points + 16 output points, or 256 output points + 16 input points |

| Built-in Analog I/O | 12-bit 4 Analog-to-Digital Converters (ADCs) / 2 Digital-to-Analog Converters (DACs) (DVP-EX2 MPU) |

| Analog Module Resolution | 14-bit |

| High-Speed Inputs | 8 points (2x 100kHz, 6x 10kHz), supporting U/D, U/D Dir, A/B counting modes |

| Power Supply Voltage | 100-240VAC, 50/60Hz |

| Power Consumption | 30VA |

| DC24V Current Output | 500mA |

| Instruction Execution Speed | 0.35 μs per basic instruction |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -25°C to 70°C |

| IP Rating | IP20 |

| Mounting | DIN rail |

| Programming Software | ISPSoft |

Core Features & Market Positioning

The Delta DVP40ES200R belongs to the DVP-ES2 series, which is positioned as a cost-effective solution for basic sequential control applications. Its market advantage lies in its high efficiency, functional versatility, and competitive pricing. The PLC boasts a 32-bit CPU for high-speed processing, crucial for demanding automation tasks. Furthermore, it features built-in analog I/O capabilities (12-bit ADCs/DACs), which are often found in higher-tier models, offering enhanced flexibility for applications requiring analog signal processing. The inclusion of multiple communication ports (RS-232 and RS-485) that can operate independently as Master or Slave further enhances its integration capabilities within complex industrial networks.

Key Application Scenarios

The Delta DVP40ES200R is well-suited for a broad range of industrial automation tasks, including:

Assembly and Packaging Machines: Its precise control and high-speed capabilities make it ideal for coordinating complex movements in automated assembly and packaging lines. Material Transfer and Storage Automation: Efficiently manages automated storage and retrieval systems (AS/RS) and material handling equipment. Batching and Process Sequencing: Executes precise batching operations and complex process control sequences in manufacturing. Machine-Level Lighting and Energy Control: Optimizes energy consumption through intelligent control of lighting and other machine-level systems. Water Treatment and Pumping Solutions: Provides reliable control for water purification, distribution, and pumping operations. Multi-device Coordination Systems: Synchronizes the operation of multiple machines or devices within a larger automated system. PV Solar Tracker Applications: Features exclusive instructions and function blocks specifically designed for photovoltaic solar tracking systems. Frequency Inverter Control: Offers handy instructions for seamless integration and control of Delta's AC motor drives, enabling forward/reverse running, RUN, and STOP functions.

Practical System Integration Guidance

Integrating the Delta DVP40ES200R into existing or new systems is streamlined by its versatile communication options and modular design. The PLC supports DIN rail mounting, simplifying installation within control panels. For wiring, standard industrial practices apply, ensuring proper connections to digital and analog inputs/outputs. The PLC utilizes the ISPSoft programming software, which is user-friendly and provides efficient program editing tools.

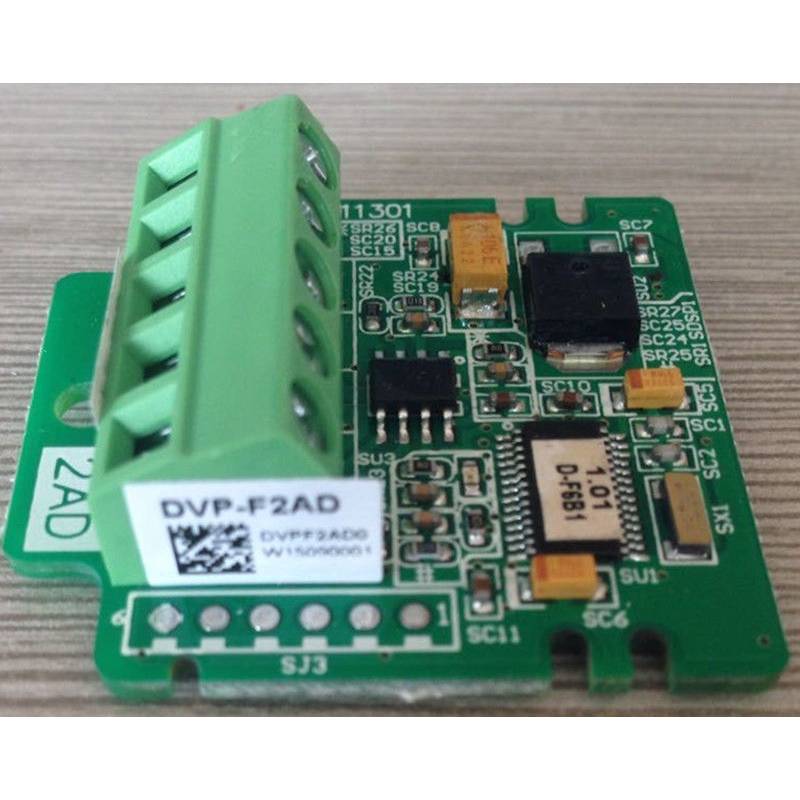

Delta's range of right-side expansion modules can be easily integrated, offering additional digital and analog I/O, load cell, temperature, and communication modules, thereby enhancing the system's scalability and functionality. The DVP40ES200R also integrates smoothly with other Delta automation products, such as Variable Frequency Drives (VFDs), Human-Machine Interfaces (HMIs), and servo drives, enabling comprehensive automation solutions. For users requiring advanced connectivity, Delta offers IIoT solutions like the DIACloud platform, which facilitates remote monitoring, data collection, and communication with devices via protocols like Modbus RTU/ASCII.

Operation and Risk Mitigation

Safe operation of the Delta DVP40ES200R involves adherence to standard electrical safety protocols. Proper grounding of the PLC is essential, especially when multiple units are in use. The PLC is designed for an operating temperature range of 0°C to 55°C and should be installed in an enclosure to protect it from dust and humidity, adhering to pollution degree 2 standards.

While specific fault codes are detailed in the operation manual, general troubleshooting often involves checking wiring integrity, ensuring correct power supply, and verifying program logic. Common issues with I/O modules, such as no signal, communication errors, or noise interference, can disrupt automation processes. Roc Industrial LLC specializes in repairing Delta PLC I/O modules, offering expertise in diagnosing and resolving such issues, often including a warranty on repairs. Password protection features are available for subroutines and user IDs, safeguarding source programs and intellectual property.

Scalability & Long-Term Value

The Delta DVP40ES200R offers significant scalability through its compatibility with Delta's extensive range of expansion modules. This allows users to expand the PLC's I/O capacity and add specialized functionalities as their automation needs evolve. The ability to integrate with Delta's VFDs, servo drives, and HMIs provides a cohesive ecosystem for building sophisticated control systems.

In terms of long-term value, the DVP-ES2 series is designed for reliability and efficient performance. Delta's commitment to developing innovative products and providing comprehensive solutions, including IIoT capabilities, ensures that systems built around the DVP40ES200R can adapt to future industry trends like smart manufacturing and Industry 4.0. The availability of programming software like ISPSoft and support for various communication protocols further enhances its long-term viability and ease of maintenance.

Frequently Asked Questions (FAQs)

1. What are the primary advantages of the Delta DVP40ES200R PLC?

The DVP40ES200R offers a strong combination of features for its class. Its key advantages include a high-speed 32-bit CPU, built-in analog I/O, and three independent communication ports.

This PLC is designed for basic sequential control, providing efficiency and functionality at a competitive price point, making it an economical choice for many industrial automation projects.

The model's versatility is further enhanced by its compatibility with Delta's expansion modules and its ability to integrate seamlessly with other Delta automation products, offering robust scalability.

2. How can I integrate the Delta DVP40ES200R into an existing network?

Integration is facilitated by its multiple communication ports. The PLC features one RS-232 and two RS-485 ports, all capable of independent Master/Slave operation.

This allows it to communicate using protocols like Modbus RTU/ASCII, enabling connection to various industrial devices and systems. You can also leverage Delta's IIoT solutions for cloud connectivity.

For networking, ensure correct wiring and configuration of communication parameters such as baud rate, parity, and slave addresses within the PLC's programming software.

3. What types of applications is the DVP40ES200R best suited for?

This PLC excels in applications requiring basic sequential control and moderate complexity. It is ideal for tasks like machine automation, assembly lines, and packaging machinery.

Its built-in analog capabilities make it suitable for processes involving analog signal inputs or outputs, such as temperature control or position feedback systems.

The DVP40ES200R also features specialized instructions for motion control and PV solar trackers, broadening its application scope in niche industrial sectors.

4. Can the Delta DVP40ES200R be expanded with additional I/O modules?

Yes, the DVP40ES200R supports expansion through Delta's right-side expansion modules. This allows for increased digital and analog I/O points.

Users can add modules for load cells, temperature sensing, and various communication interfaces, tailoring the PLC's capabilities to specific project requirements.

This modular approach ensures the system can scale as automation needs grow, offering a cost-effective way to enhance functionality without replacing the entire PLC.

5. What programming software is used for the Delta DVP40ES200R?

The primary programming software for the Delta DVP40ES200R is ISPSoft. This software is part of Delta's DIAStudio suite and is designed for efficient PLC programming.

ISPSoft supports various programming languages, including Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST), providing flexibility for different user preferences and application complexities.

The software also offers simulation capabilities, allowing engineers to test and debug their programs offline before deploying them to the PLC, thereby reducing commissioning time and potential errors.

6. How does the DVP40ES200R handle high-speed counting and motion control?

The DVP40ES200R is equipped with eight high-speed input points (two at 100kHz, six at 10kHz) that support various counting modes. This enables precise tracking of rapid events or positions.

It also includes new motion control instructions such as closed-loop control, alignment mark, and S-curve acceleration/deceleration. These instructions facilitate high-precision positioning and dynamic motion tasks.

These capabilities make the PLC suitable for applications like servo control, precise indexing, and complex coordinated motion sequences, often integrated with Delta's servo drives.

7. What are the power supply requirements for the Delta DVP40ES200R?

The DVP40ES200R operates on a wide AC power supply range of 100 to 240VAC, with a frequency tolerance of 50/60Hz ±5%. This broad range ensures compatibility with various power grids globally.

The unit has a low power consumption of approximately 30VA, contributing to energy efficiency in control panels. It also provides a 24VDC output at 500mA for powering external sensors or devices.

Proper connection to a stable AC power source and adherence to wiring guidelines are crucial for reliable operation and to prevent damage to the unit.

8. How does the DVP40ES200R support connectivity with other industrial devices?

Connectivity is a strong point, thanks to its built-in RS-232 and dual RS-485 ports, which can be configured independently. This supports communication via protocols like Modbus RTU/ASCII.

It can also interface with Delta's VFDs, HMIs, and servo drives, forming a cohesive automation solution. Expansion modules can add further communication options, such as industrial Ethernet.

For advanced applications, Delta's IIoT platform, DIACloud, can be utilized for remote monitoring and data exchange with the PLC.

9. What safety considerations should be taken when operating the Delta DVP40ES200R?

Standard industrial safety practices are paramount. Ensure proper grounding of the unit to prevent electrical hazards and signal interference.

Install the PLC within a suitable enclosure to protect it from environmental factors like dust, moisture, and extreme temperatures, adhering to its IP20 rating.

Always refer to the official operation manual for specific safety instructions, emergency stop procedures, and wiring guidelines to mitigate risks and ensure safe operation.

10. What is the difference between the DVP40ES200R and DVP40ES200T models?

The main difference lies in their output types. The DVP40ES200R features relay outputs, which are versatile and can switch higher AC or DC loads.

Conversely, the DVP40ES200T model is equipped with transistor (NPN) outputs, typically used for faster switching and lower power DC loads, often preferred in applications with frequent output changes.

Both models share the same CPU, memory, communication capabilities, and core functionalities, making the choice primarily dependent on the specific output requirements of the application.