The Delta ASD-E3-0721-E Universal Standard Servo System is engineered for robust industrial applications, delivering precision, reliability, and efficiency. This system stands out with its advanced features, including high-speed response, superior motion control accuracy, and comprehensive protection functions. Key technical specifications include a voltage range of 200-230VAC, a motor capacity of 750W (1HP), and an IP20 protection rating, making it suitable for a demanding industrial environment. The ASD-E3 series emphasizes ease of integration and operation, positioning itself as a versatile solution for a wide array of automated manufacturing processes.

Product Specifications

| Feature | Specification |

| :---------------------- | :------------------------------------------- |

| Model | ASD-E3-0721-E |

| Series | ASD-E3 Universal Standard Servo System |

| Input Voltage | 200-230 VAC |

| Motor Capacity | 750W (1 HP) |

| Output Current | 5.0 A |

| Frequency Response | 1 kHz |

| Protection Rating | IP20 |

| Communication Interfaces | CANopen, RS-485 |

| Encoder Support | Incremental, Absolute (17-bit, 20-bit) |

| Built-in Functions | Auto-Tuning, Vibration Suppression, Position |

| Operating Temperature | 0°C to 50°C |

Core Features & Market Positioning

The Delta ASD-E3-0721-E Universal Standard Servo System distinguishes itself in the competitive industrial automation market through its blend of advanced control algorithms and user-centric design. Its 1kHz frequency response ensures rapid and precise control, crucial for high-speed pick-and-place operations and complex synchronized movements. The system's inherent ability to support both incremental and absolute encoders, with resolutions up to 20-bit, provides users with flexibility in choosing feedback devices suited to their application's accuracy requirements. Furthermore, integrated auto-tuning and vibration suppression capabilities significantly reduce setup time and enhance operational smoothness, minimizing mechanical wear and tear. This positions the ASD-E3 series as a highly competitive offering for industries prioritizing performance, ease of use, and long-term reliability.

Key Application Scenarios

This versatile servo system finds extensive application across numerous industrial sectors where precise and dynamic motion control is paramount. It is ideally suited for packaging machinery, enabling high-speed filling, sealing, and labeling operations with exceptional accuracy. In the electronics manufacturing domain, the ASD-E3-0721-E excels in automated assembly lines, wafer handling, and precision component placement. Material handling equipment, such as automated guided vehicles (AGVs) and robotic arms used in logistics and warehousing, benefits from its robust performance and reliable positioning capabilities. Furthermore, its suitability for textile machinery, metalworking, and printing equipment underscores its broad applicability in achieving intricate movements and consistent operational quality.

Practical System Integration Guidance

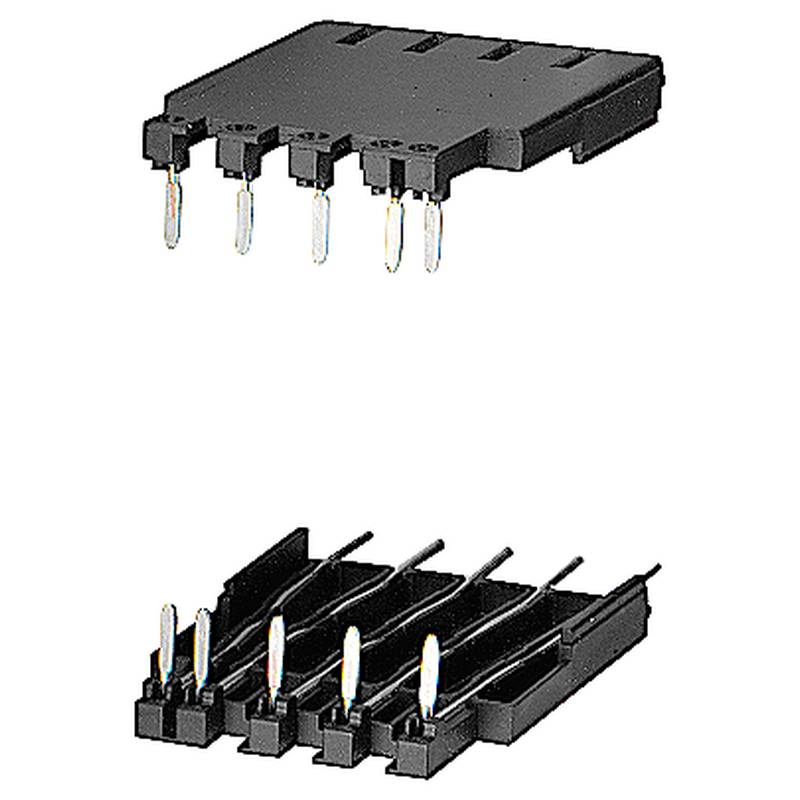

Integrating the Delta ASD-E3-0721-E into an existing industrial control architecture is streamlined due to its standard communication protocols and comprehensive documentation. The system supports both CANopen and RS-485 interfaces, allowing for seamless integration with a wide range of Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs). Wiring requires careful adherence to the provided schematics, particularly concerning power supply, motor connections, and encoder feedback. For initial setup, the Delta-Link software is essential for parameter configuration, including motor tuning, setting operational modes (position, velocity, torque), and establishing communication links. Commissioning typically involves performing the auto-tuning function to optimize servo performance based on the connected motor's characteristics.

Operation and Risk Mitigation

Operating the Delta ASD-E3-0721-E requires adherence to safety protocols and an understanding of its fault diagnostic features. Proper grounding and electrical isolation are critical to prevent damage and ensure personnel safety. The system incorporates numerous protection mechanisms, including overcurrent, overvoltage, undervoltage, and thermal overload protection, which automatically halt operation and log error codes when detected. Common troubleshooting involves consulting the user manual for specific error code explanations. For instance, an "overload" fault might indicate a mechanical binding issue or a motor operating beyond its capacity, necessitating a review of the application's load requirements and mechanical system integrity. Regular maintenance, such as checking connections and ensuring adequate ventilation, further mitigates operational risks.

Scalability & Long-Term Value

The Delta ASD-E3-0721-E Universal Standard Servo System offers significant scalability and long-term value, primarily through its compatibility and integration potential. Its modular design and support for standard industrial communication protocols like CANopen facilitate upgrades and expansion of automation systems. Users can easily integrate multiple ASD-E3 drives into a larger network controlled by a single PLC, allowing for synchronized operation of complex machinery. Furthermore, Delta's commitment to developing its product line means that the ASD-E3 series can be readily incorporated into evolving industrial Internet of Things (IIoT) and Industry 4.0 initiatives. Its robust construction and Delta's reputation for reliable industrial automation solutions ensure a long operational lifespan, minimizing total cost of ownership.

Frequently Asked Questions

Q1: What are the primary advantages of the Delta ASD-E3-0721-E servo system?

This servo system offers high-speed response for demanding tasks. It provides precise motion control for accurate automation. Its advanced protection functions enhance operational reliability and safety.

Q2: What types of encoders can be used with the ASD-E3-0721-E?

The system supports incremental encoders for basic feedback needs. It is also compatible with absolute encoders for precise position tracking. Resolutions up to 20-bit ensure high accuracy in feedback.

Q3: How does the auto-tuning feature benefit users?

Auto-tuning simplifies the setup process significantly. It optimizes servo performance automatically for the connected motor. This reduces manual configuration effort and time.

Q4: What communication protocols does the ASD-E3-0721-E support?

It integrates easily using the CANopen industrial communication standard. The RS-485 serial interface is also available for broader connectivity. This ensures compatibility with many control systems.

Q5: What are common applications for this servo system?

It is widely used in packaging and assembly machinery. Electronics manufacturing benefits from its precision for component placement. Material handling and robotics also utilize its capabilities.

Q6: What is the typical input voltage range for this servo?

The system operates with a standard industrial voltage of 200-230 VAC. This range is common in many manufacturing facilities globally. It simplifies power supply planning.

Q7: How can I troubleshoot common faults with the ASD-E3-0721-E?

Consult the official user manual for detailed error code explanations. Verify mechanical systems for binding or excessive load issues. Ensure motor and encoder connections are secure and correct.

Q8: Does the ASD-E3-0721-E support vibration suppression?

Yes, the system includes built-in vibration suppression algorithms. These algorithms help to smooth out motor movements. This leads to quieter and more stable operation.

Q9: What is the motor capacity of the Delta ASD-E3-0721-E?

This specific model is rated for a 750W motor capacity. This corresponds to approximately 1 HP of power output. It is suitable for medium-duty industrial applications.

Q10: How does this servo system contribute to IIoT and Industry 4.0 integration?

Its standard communication interfaces facilitate data exchange. It can be networked with other devices for a connected factory. This enables advanced analytics and remote monitoring capabilities.