The Delta ECM-B3M-CA1010RS1 Resolver Encoder Servo Motor is engineered for demanding industrial automation applications requiring precise motion control and robust performance. This motor boasts a rated power of 1 kW, a continuous stall torque of 4.77 Nm, and a peak stall torque of 9.55 Nm, making it suitable for dynamic and load-intensive operations. Its compact frame size 100 and IP65 protection rating ensure reliability even in harsh environments. Equipped with a resolver encoder, it provides high-resolution feedback for superior position and speed accuracy. The motor operates efficiently within a voltage range of 200-230V AC, featuring a maximum speed of 3000 RPM, and comes with a shaft diameter of 19 mm.

Delta ECM-B3M-CA1010RS1: Product Specifications

| Parameter | Value |

| :-------------------- | :------------------------------------- |

| Rated Power | 1 kW |

| Rated Voltage | 200-230V AC |

| Rated Torque | 3.18 Nm |

| Continuous Stall Torque | 4.77 Nm |

| Peak Stall Torque | 9.55 Nm |

| Rated Speed | 3000 RPM |

| Frame Size | 100 |

| Encoder Type | Resolver |

| Protection Class | IP65 |

| Shaft Diameter | 19 mm |

| Brake | Without Brake |

| Shaft Extension | Standard Keyway |

Core Features & Market Positioning

The Delta ECM-B3M-CA1010RS1 stands out in the competitive servo motor market due to its inherent ruggedness and precision feedback system. The integrated resolver encoder offers exceptional durability and resistance to environmental factors like dust and oil, which are common in industrial settings, compared to optical encoders. This makes it a preferred choice for applications where high reliability under challenging conditions is paramount. Its robust construction, highlighted by the IP65 rating, signifies its capability to withstand water jets and dust ingress, ensuring continuous operation without performance degradation. Furthermore, the motor's high torque density allows for compact system designs without compromising on power, a significant advantage for space-constrained automation solutions. Delta's reputation for quality and performance further solidifies its market position as a trusted provider of motion control components for demanding industries.

Key Application Scenarios

This servo motor is ideally suited for a wide array of industrial automation tasks that demand precise, dynamic motion control. Its high torque capabilities and reliable feedback make it an excellent choice for CNC machinery, robotic arms in assembly lines, and automated packaging equipment where accuracy and speed are critical. The ECM-B3M-CA1010RS1 is also well-suited for material handling systems, printing presses, and textile machinery that require consistent and repeatable movements. For applications operating in dirty or wet environments, such as food processing or metal fabrication, the IP65 rating ensures long-term operational integrity. Its versatility extends to industries requiring synchronized movements, like those found in automated warehousing and automated guided vehicle (AGV) systems.

Practical System Integration Guidance

Integrating the Delta ECM-B3M-CA1010RS1 servo motor into existing systems requires careful consideration of its power and feedback connections. The motor is designed to be driven by compatible Delta servo drives, ensuring optimal performance and simplified setup. For wiring, ensure proper grounding and use shielded cables to prevent electromagnetic interference, particularly with the resolver feedback signals. The standard keyway on the shaft facilitates easy mechanical coupling with various transmissions, such as gearboxes or ball screws. Commissioning typically involves configuring the servo drive parameters to match the motor's specifications, including its torque constants, inertia, and encoder resolution, to achieve precise control loops. Always refer to the specific servo drive's manual for detailed wiring diagrams and configuration steps relevant to the ECM-B3M-CA1010RS1.

Operation and Risk Mitigation

Safe operation of the Delta ECM-B3M-CA1010RS1 servo motor mandates adherence to electrical safety standards and proper application of its control system. Before performing any maintenance or wiring, always ensure the power supply to the servo drive is completely disconnected and locked out. Overheating is a potential risk; ensure adequate ventilation around the motor and drive, and monitor motor temperature during operation, especially under high load conditions. Fault codes generated by the connected servo drive often indicate issues such as overcurrent, overvoltage, or encoder faults. For example, an encoder fault might require checking the resolver wiring integrity or inspecting the encoder for physical damage. Always consult the servo drive's diagnostic information and error code listings for specific troubleshooting procedures to mitigate operational risks and ensure system longevity.

Scalability & Long-Term Value

The Delta ECM-B3M-CA1010RS1 servo motor offers significant long-term value through its integration capabilities and robust design. Its compatibility with Delta's broader range of servo drives and automation components allows for scalable solutions, enabling systems to grow and adapt to evolving production needs. This interoperability simplifies upgrades and expansions, reducing re-engineering costs. Furthermore, the durable construction and reliable resolver feedback contribute to a longer service life, minimizing downtime and maintenance expenses. For facilities looking to implement Industry 4.0 initiatives, Delta's servo systems can be integrated with IIoT platforms, providing valuable data for predictive maintenance and process optimization, thereby enhancing overall operational efficiency and return on investment.

Frequently Asked Questions

What are the primary advantages of using a resolver encoder in the Delta ECM-B3M-CA1010RS1 servo motor?

Resolver encoders offer superior robustness against harsh industrial environments, including dust, oil, and vibration. This inherent durability leads to increased reliability and reduced maintenance compared to optical encoders. The ECM-B3M-CA1010RS1 leverages this for consistent performance in demanding applications.

Resolver encoders are known for their inherent absolute positioning capabilities and fail-safe nature. This means they can often retain position information even after power cycles or unexpected shutdowns. The motor's design prioritizes operational continuity and data integrity in critical processes.

The simplified construction of resolver encoders contributes to their cost-effectiveness over the long term. While initial sensor costs might be comparable, their longevity and resistance to failure often result in lower total cost of ownership. This makes the ECM-B3M-CA1010RS1 a practical choice for budget-conscious yet performance-driven projects.

How does the IP65 protection rating benefit the Delta ECM-B3M-CA1010RS1 servo motor in industrial settings?

The IP65 rating signifies that the motor is dust-tight and protected against low-pressure water jets from any direction. This is crucial for operational continuity in environments prone to significant dust accumulation or frequent washdowns. The ECM-B3M-CA1010RS1 can therefore maintain performance in manufacturing floors, food processing plants, or chemical facilities.

This level of ingress protection significantly reduces the risk of internal component damage caused by contaminants. Preventing dust and water from reaching the motor windings and bearings extends its lifespan and minimizes unplanned downtime. This enhances the overall reliability of automated systems employing this motor.

Implementing machinery with IP65-rated components like the ECM-B3M-CA1010RS1 simplifies maintenance and cleaning protocols. Operators can clean equipment more aggressively without concern for damaging the motor's electrical integrity. This contributes to a safer and more hygienic work environment.

What type of servo drive is recommended for the Delta ECM-B3M-CA1010RS1 servo motor?

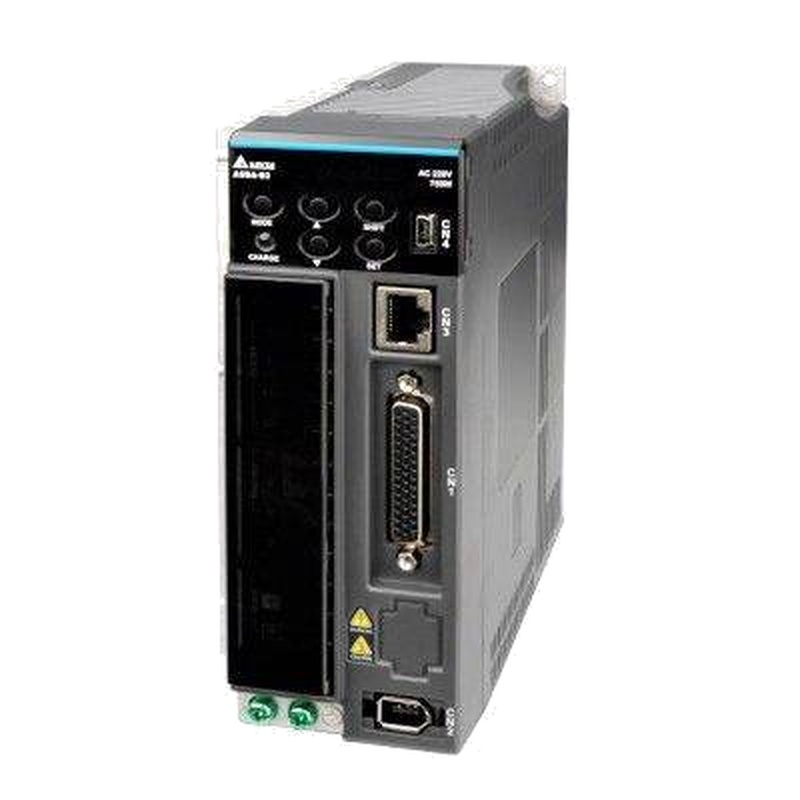

The Delta ECM-B3M-CA1010RS1 servo motor is designed for optimal performance with Delta's ASDA-B3 series servo drives. These drives are engineered to fully exploit the motor's capabilities, including its resolver feedback. Compatibility is key for achieving precise motion control.

Selecting a Delta ASDA-B3 drive ensures seamless integration of the resolver encoder signals, enabling accurate position and speed feedback loops. This facilitates advanced control features such as high-speed positioning and precise torque regulation tailored to the motor's specifications.

Using a drive from the same manufacturer typically simplifies wiring and parameter configuration. The drive's software will likely have pre-set or easily configurable profiles for the ECM-B3M-CA1010RS1, reducing commissioning time and potential setup errors.

What are the typical torque characteristics of the ECM-B3M-CA1010RS1, and why are they important?

The ECM-B3M-CA1010RS1 offers a rated torque of 3.18 Nm for continuous operation and a rated speed of 3000 RPM. This defines its standard performance envelope for consistent tasks. Understanding these figures is essential for sizing the motor appropriately for sustained workloads.

Its continuous stall torque is 4.77 Nm, indicating the maximum torque it can sustain without overheating for extended periods at zero speed. This parameter is critical for applications requiring holding torque or slow, steady movements under load.

The peak stall torque reaches 9.55 Nm, representing the motor's maximum short-duration torque capability. This is vital for applications requiring rapid acceleration, overcoming static friction, or handling transient high loads, such as those found in robotics and material handling.

Can the Delta ECM-B3M-CA1010RS1 be used in applications requiring high precision positioning?

Yes, the ECM-B3M-CA1010RS1 is specifically designed for high-precision positioning tasks. Its resolver encoder provides accurate feedback crucial for closed-loop control systems demanding exact positional accuracy. This makes it suitable for intricate automation.

The motor's ability to deliver consistent torque and speed, combined with its resolver's resolution, allows for fine adjustments in movement. This is essential for applications like pick-and-place operations, CNC machining, and automated assembly where millimeters or even microns matter.

When paired with a compatible Delta servo drive configured correctly, the ECM-B3M-CA1010RS1 can achieve very tight positioning tolerances. The drive interprets the resolver's signals to continuously correct the motor's position, ensuring it reaches and maintains the target location with minimal error.

What is the significance of the 1 kW rated power for the ECM-B3M-CA1010RS1?

The 1 kW rated power indicates the motor's continuous output power capacity under standard operating conditions. This metric is a key factor in determining the motor's suitability for various automation tasks. It defines its general performance class for sustained work.

This power rating, in conjunction with its torque and speed characteristics, helps engineers select the correct motor for their application's demands. A 1 kW motor is typically used for medium-duty industrial automation, balancing performance with physical size and energy consumption.

For tasks requiring consistent power delivery without exceeding thermal limits, the 1 kW rating ensures reliability. It suggests that the motor can handle continuous operation in many manufacturing, material handling, or robotics applications without premature wear or failure.

What are common troubleshooting steps for issues related to the resolver encoder on the ECM-B3M-CA1010RS1?

First, inspect the resolver's wiring for any signs of damage, loose connections, or corrosion. Ensure the shielded cable is properly terminated at both the motor and the servo drive ends. A faulty connection is a frequent cause of encoder errors.

Next, verify that the servo drive is correctly configured to interpret the specific resolver signals from the ECM-B3M-CA1010RS1. Incorrect parameters or incompatible drive settings can lead to communication errors or inaccurate position feedback. Consult the drive's manual for correct setup.

If wiring and configuration appear correct, the resolver itself may have failed. While robust, resolvers can be damaged by extreme impacts or severe environmental exposure over time. In such cases, the resolver may need to be replaced, often requiring replacement of the entire motor unit or a specialized repair.

How does the frame size 100 influence the motor's physical dimensions and mounting?

Frame size 100 indicates a standardized physical dimension for the motor's mounting footprint and body diameter. This size designation helps ensure interchangeability and compatibility with existing machine designs and mounting brackets that adhere to industry standards. It relates to the motor's physical build.

Motors with frame size 100 typically offer a balance between power output and compact design. This specific size designation suggests that the ECM-B3M-CA1010RS1 is suitable for applications where space is a consideration, but significant torque and power are still required.

When specifying or replacing a motor, referencing frame size 100 ensures correct mechanical fit. This standardization simplifies the integration process, reducing the need for custom modifications or adapters and ensuring that the motor will bolt directly onto compatible machine structures.

What is the role of the 19 mm shaft diameter in mechanical system integration?

The 19 mm shaft diameter is a critical mechanical interface that dictates how the motor connects to external machinery. This dimension determines the size of couplings, pulleys, sprockets, or gearbox input shafts that can be directly attached to the motor. It's a fundamental aspect of mechanical linkage.

This specific shaft diameter is common in many industrial automation applications, facilitating compatibility with a wide range of standard power transmission components. It allows for the transmission of the motor's torque to the driven load effectively and reliably.

When designing or integrating systems, ensuring that mating components are sized for a 19 mm shaft is essential. Using the correct coupling ensures efficient power transfer and minimizes stress on the motor shaft and bearings, contributing to the overall longevity and performance of the equipment.

Does the Delta ECM-B3M-CA1010RS1 servo motor include a brake, and what are the implications?

The Delta ECM-B3M-CA1010RS1 servo motor, as specified with the "CA1010RS1" model number, does not include an integrated brake. Motors without brakes are typically used in applications where external braking mechanisms are employed or where the load is always powered or held by another means. This absence affects holding capabilities.

For applications requiring the motor to hold a load in position when power is removed, an external brake or a servo drive with holding brake control capabilities would be necessary. This is crucial for safety in vertical axis applications or where unexpected power loss could lead to load movement.

When selecting a servo motor, the presence or absence of a brake is a key consideration. For the ECM-B3M-CA1010RS1, users must account for this and ensure their system design includes provisions for load holding if required, potentially adding complexity or cost to the overall solution.